- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

des . 05, 2024 03:04 Back to list

Exploring the Benefits and Applications of Aluminium Die Casting in Modern Manufacturing

The Importance of Aluminium Die Casting in Modern Manufacturing

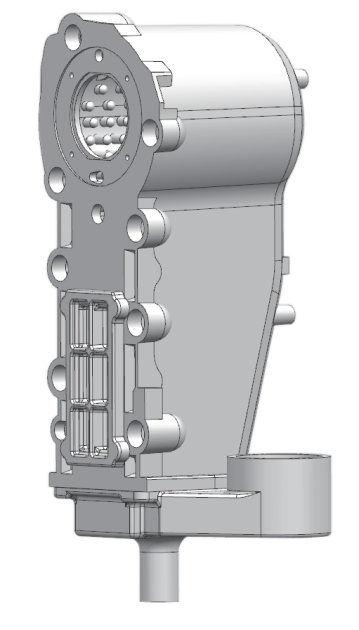

Aluminium die casting is a manufacturing process that has gained significant traction in various industries due to its many advantages, including lightweight properties, durability, and design flexibility. This technique involves forcing molten aluminium into a mold at high pressure, resulting in precision-engineered components that are essential for modern applications ranging from automotive to electronics and consumer goods.

One of the primary benefits of aluminium die casting is its lightweight nature. Aluminium is significantly lighter than other metals such as steel and iron, making it an excellent choice for applications where weight reduction is crucial. For instance, in the automotive industry, lighter components contribute to better fuel efficiency and improved performance. As manufacturers strive to meet stringent environmental regulations and consumer demands for fuel-efficient vehicles, aluminium die casting has become an integral process in producing engine blocks, transmission cases, and various other components.

Moreover, the durability of aluminium die cast parts adds significant value. Aluminium exhibits remarkable resistance to corrosion, which is particularly important in applications exposed to harsh environments. The high strength-to-weight ratio of aluminium ensures that components can withstand considerable stress without compromising on performance. This resilience makes aluminium die casting an ideal choice for industries such as aerospace and marine, where components must endure extreme conditions.

Another significant advantage of aluminium die casting is its ability to produce parts with intricate designs and thin walls

. Manufacturers can create complex shapes that would be difficult or impossible to achieve with traditional machining methods. This design flexibility allows engineers to innovate and optimize component designs, leading to better product performance and reduced manufacturing costs. Furthermore, the ability to achieve tighter tolerances means that less machining is required post-casting, which further enhances efficiency and cost-effectiveness in production.aluminium die casting

The die casting process itself is also highly efficient. Once the die (the mold) is created, it can be used repeatedly to produce thousands of identical parts, ensuring consistency and reliability in production. Automation in the die casting process has further increased efficiency, allowing manufacturers to scale production and respond quickly to changing market demands. With advancements in technology, including the use of computer-aided design (CAD) and simulation software, manufacturers can also anticipate potential issues and optimize the casting process before it even begins.

In ecological terms, aluminium die casting is considered a sustainable manufacturing process. Aluminium is highly recyclable, and recycled aluminium requires significantly less energy to produce compared to new aluminium. This aspect not only reduces the environmental impact of production but also supports a circular economy where materials are reused continually. As industries increasingly focus on sustainability, the demand for environmentally friendly manufacturing practices continues to rise, making aluminium die casting an attractive option.

However, like any manufacturing process, aluminium die casting does face certain challenges. The initial cost of producing dies can be high, particularly for complex designs. Additionally, achieving a consistent quality in castings requires careful control of the casting process and thorough quality checks, which can add to production costs. Despite these challenges, the numerous advantages of aluminium die casting often outweigh the drawbacks, making it a favored choice for many manufacturers.

In conclusion, aluminium die casting plays a crucial role in modern manufacturing by combining lightweight, durable materials with innovative design capabilities. Its efficiency, sustainability, and versatility make it an attractive option across multiple industries. As technology continues to advance and consumer demands evolve, the relevance of aluminium die casting will only grow stronger, paving the way for new possibilities and applications in the manufacturing landscape.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025