- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

okt . 17, 2024 14:37 Back to list

Innovative Techniques for Enhancing Ductile Iron Production and Quality Optimization

Ductile Iron Production An Overview

Ductile iron, also known as ductile cast iron or spheroidal graphite iron, is a type of cast iron that exhibits exceptional strength and ductility, making it a preferred material for various applications ranging from automotive components to infrastructure products. The unique properties of ductile iron result from its microstructure, primarily characterized by the presence of spheroidal graphite inclusions. This article delves into the production process of ductile iron, its advantages, applications, and environmental considerations.

Production Process

The production of ductile iron involves several critical stages, including material selection, melting, alloying, casting, and heat treatment. The primary raw material used is pig iron, along with scrap iron and other alloying elements. The melting process typically occurs in either an electric arc furnace (EAF) or a cupola furnace, where the raw materials are heated to high temperatures.

Melting and Alloying

Upon reaching the desired temperature, the molten iron is treated with a magnesium-containing alloy, usually ferrosilicon magnesium. This addition is crucial as it promotes the formation of spheroidal graphite during the solidification process. The magnesium treatment can be performed either in the ladle or in the furnace depending on the production method and desired properties.

Once the magnesium is added, the molten iron must be cast promptly to prevent any loss of the beneficial effects of magnesium. Careful control of temperature and time is vital during this stage to ensure optimum material properties.

Casting

Ductile iron can be cast into various forms using sand molding, permanent mold casting, or investment casting techniques. The choice of casting method often depends on factors such as production volume, complexity of the part geometry, and dimensional requirements. Once the molten iron is poured into molds and solidifies, it undergoes removal and finishing processes, including trimming, grinding, and machining.

Heat Treatment

To further enhance the mechanical properties of ductile iron components, a heat treatment process known as annealing is often employed. This process involves heating the cast parts to a specific temperature followed by controlled cooling, which improves ductility and reduces residual stresses. Other treatments like normalizing or quenching and tempering can also be applied based on the requirements for specific applications.

ductile iron production

Advantages of Ductile Iron

The advantages of ductile iron over traditional cast iron are manifold. Its unique microstructure provides excellent tensile strength, toughness, and fatigue resistance, making it suitable for high-stress applications. Unlike brittle cast iron, ductile iron’s ability to deform under stress minimizes the risk of catastrophic failure, a crucial feature in safety-critical components.

Moreover, ductile iron exhibits better machinability compared to other iron alloys, allowing for precision manufacturing processes. Its versatility allows it to be alloyed with various elements to achieve desired properties for specific applications, such as increased corrosion resistance or improved weldability.

Applications

The versatile properties of ductile iron have led to its widespread use across various industries. In the automotive sector, it is used for components such as crankshafts, connecting rods, and housings that require high strength-to-weight ratios. Infrastructure applications include pipes, valves, and fittings for water and wastewater systems, where durability and corrosion resistance are paramount.

Ductile iron’s excellent wear resistance makes it suitable for manufacturing machinery parts and industrial equipment. Additionally, its aesthetic appeal has made it a popular choice for architectural elements and decorative features.

Environmental Considerations

As the world places greater emphasis on sustainability, ductile iron production faces its share of environmental challenges. The melting of metals contributes to greenhouse gas emissions, and managing resource consumption is critical. Manufacturers are increasingly adopting technologies for recycling scrap metal, implementing energy-efficient processes, and exploring the use of alternative, less polluting materials in alloy production.

Through the combination of advanced recycling practices and the development of more sustainable production methods, the ductile iron industry can continue to thrive while minimizing its ecological footprint.

Conclusion

Ductile iron production remains a cornerstone of many industries due to its remarkable strength, ductility, and versatility. As technology advances and the push for sustainability grows stronger, the methods and practices associated with ductile iron manufacturing will likely evolve, ensuring that this valuable material continues to meet modern engineering and environmental standards.

-

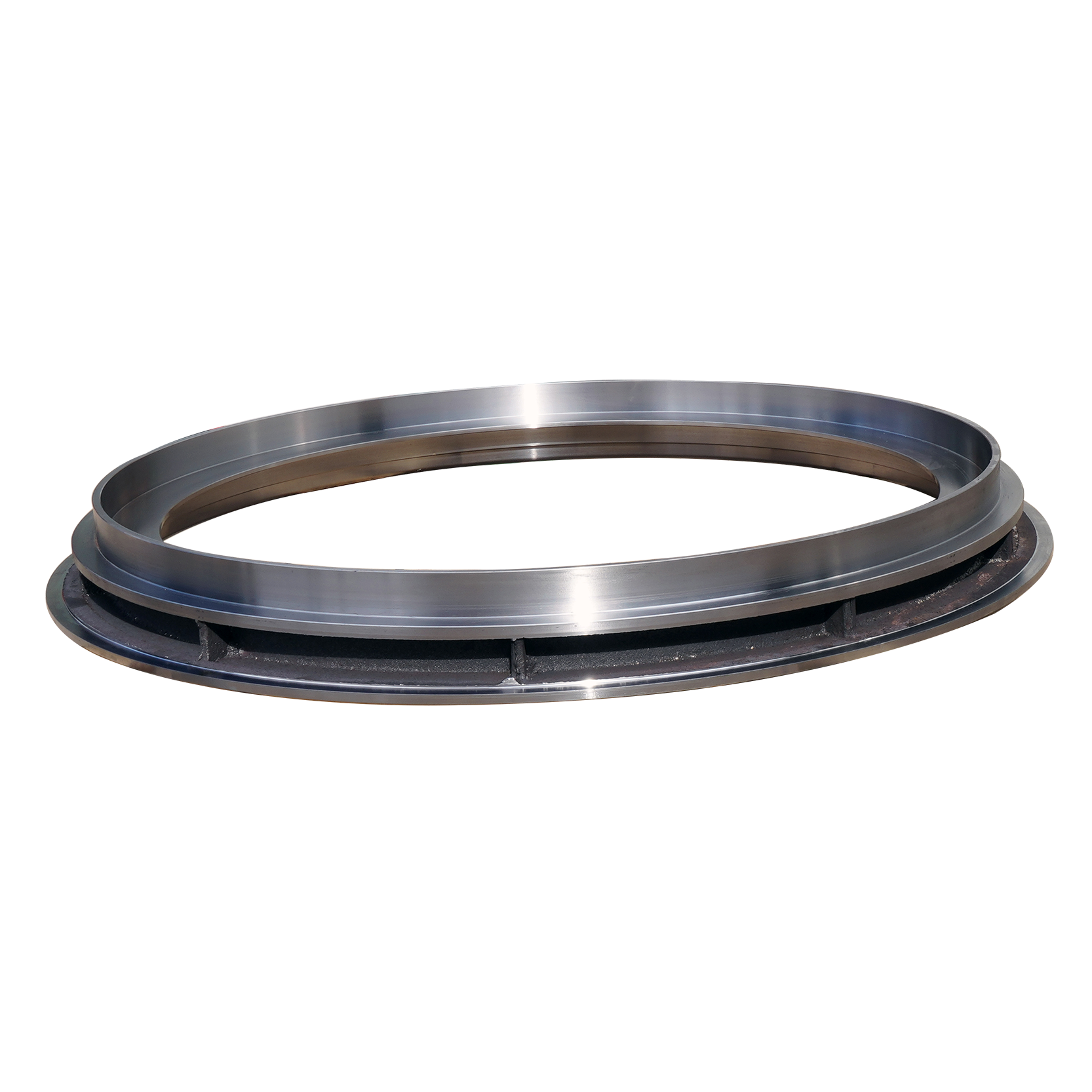

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025