- アフリカ人

- アルバニア人

- アムハラ語

- アラビア語

- アルメニア語

- アゼルバイジャン語

- バスク語

- ベラルーシ語

- ベンガル語

- ボスニア語

- ブルガリア語

- カタルーニャ語

- セブアノ語

- 中国

- 中国(台湾)

- コルシカ島

- クロアチア語

- チェコ語

- デンマーク語

- オランダの

- 英語

- エスペラント

- エストニア語

- フィンランド語

- フランス語

- フリジア語

- ガリシア語

- ジョージア語

- ドイツ人

- ギリシャ語

- グジャラート語

- ハイチ クレオール

- ハウサ語

- ハワイアン

- ヘブライ語

- いいえ

- ミャオ族

- ハンガリー語

- アイスランド語

- イボ語

- インドネシア語

- アイルランド人

- イタリアの

- 日本

- ジャワ語

- カンナダ語

- カザフ語

- クメール語

- ルワンダ語

- 韓国語

- クルド

- キルギス

- 労働

- ラテン

- ラトビア語

- リトアニア語

- ルクセンブルク語

- マケドニアの

- マルガシ

- マレー語

- マラヤーラム語

- マルタ語

- マオリ語

- マラーティー語

- モンゴル語

- ミャンマー

- ネパール語

- ノルウェー語

- ノルウェー語

- オック語

- パシュトゥー語

- ペルシア語

- 研磨

- ポルトガル語

- パンジャブ語

- ルーマニア語

- ロシア

- サモア語

- スコットランド・ゲール語

- セルビア語

- 英語

- ショナ

- シンド語

- シンハラ語

- スロバキア語

- スロベニア語

- ソマリ語

- スペイン語

- スンダ人

- スワヒリ語

- スウェーデンの

- タガログ語

- タジク語

- タミル語

- タタール語

- テルグ語

- タイ語

- トルコ語

- トルクメン語

- ウクライナ語

- ウルドゥー語

- ウイグル語

- ウズベク語

- ベトナム語

- ウェールズ語

- ヘルプ

- イディッシュ語

- ヨルバ語

- ズールー語

3月 . 10, 2025 13:55 リストに戻る

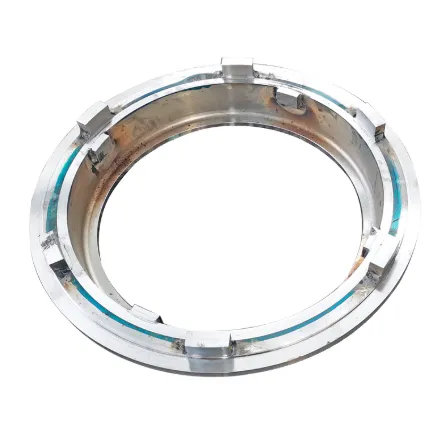

Cast Iron Pipe Mold Pallets in Infrastructure Development

In the infrastructure development industry, the quality and precision of the materials used in production are essential for ensuring the longevity and safety of the systems being built. One of the most crucial components for producing robust, durable pipes used in water supply and sewage systems is the ductile iron pipe mould pallet. Along with other mold options like stamping concrete pipe mold pallets and punching concrete pipe mold pallets, ductile iron pipe mould pallets stand out for their exceptional strength and reliability. Let's explore the importance of these pallets in the infrastructure sector and why they are indispensable for modern pipeline production.

The Role of Ductile Iron Pipe Mould Pallets in Pipe Production

The ductile iron pipe mould pallet is a key component in ensuring high-quality pipe production, especially for infrastructure projects that involve water supply, sewage, and stormwater systems. The unique properties of ductile iron pipe mould pallets allow them to endure the stress and weight of the concrete during the casting process, making them the ideal choice for forming pipes that need to be strong, flexible, and resistant to cracking.

By using ductile iron pipe mould pallets, manufacturers ensure precision in each mold. This consistency in production is crucial for maintaining the structural integrity of the pipes, which are designed to handle high-pressure loads, environmental stress, and the harsh conditions that they may face underground or in industrial applications. The durability of these pallets is a contributing factor to the overall strength of the pipe, ensuring that it performs reliably in critical infrastructure systems for many years.

Benefits of Stamping Concrete Pipe Mold Pallets in Mass Production

When it comes to mass production of pipes for large-scale infrastructure projects, stamping concrete pipe mold pallets offer distinct advantages. These pallets are designed to handle the complexities of high-volume production while maintaining precision and consistency. Stamping concrete pipe mould pallets are made from high-quality materials that are able to withstand the intense pressures involved in molding heavy concrete.

For large-scale infrastructure development, stamping concrete pipe mould pallets ensure that each pipe is produced quickly, efficiently, and to the exact specifications required. The uniformity achieved through the use of these pallets significantly reduces the risk of defective pipes, leading to fewer repairs and replacements during the long-term use of the pipes in water or sewage systems. Additionally, the stamping process helps in reducing labor costs and manufacturing time, contributing to overall cost savings for infrastructure projects.

Punching Concrete Pipe Mold Pallets for Efficient and Precise Production

In the manufacturing of concrete pipes, the precision of the mold plays a vital role in ensuring the proper fitting and functionality of each pipe. Punching concrete pipe mold pallets are designed to offer excellent precision during the casting process, particularly when it comes to shaping pipes that need to adhere to strict standards for diameter, wall thickness, and length.

The precision that punching concrete pipe mold pallets provide is essential for creating pipes that meet the rigorous demands of infrastructure projects. Pipes must fit together seamlessly in water supply or sewage systems, ensuring that there are no gaps or misalignments. These pallets help achieve the desired level of precision with every cast, preventing costly errors during installation.

Durability and Cost-Effectiveness in Infrastructure Projects with pipe mould pallets

The durability of ductile iron pipe mould pallets, along with stamping concrete pipe mold pallets and punching concrete pipe mold pallets, is key to their value in infrastructure development. High-quality mold pallets made from durable materials can be used repeatedly, offering long-term cost savings. The robust construction of these pallets reduces the need for frequent replacements, and their resilience ensures that each pipe cast maintains the highest standards of quality.

Cast iron pipe mold pallets are often favored for their resistance to corrosion, making them ideal for pipes that will be used in both water and sewage systems. This durability ensures that the pipes can withstand environmental pressures without compromising their integrity. Additionally, these mold pallets help improve production speed while maintaining precision, leading to better productivity and lower costs in large-scale infrastructure projects.

As infrastructure projects become more complex and require larger quantities of materials, ensuring that pipes are produced consistently and to the highest standards is critical. The ductile iron pipe mould pallet plays a significant role in achieving this consistency. By maintaining uniformity in the size, shape, and strength of the pipes, these pallets help avoid potential issues down the line, such as pipe failures or the need for repairs.

For projects that involve critical applications like sewage treatment plants, water distribution systems, or stormwater management, the reliability of the pipe molds is essential. Stamping concrete pipe mold pallets and punching concrete pipe mold pallets further enhance the consistency of production, ensuring that the pipes meet all necessary industry standards and local regulations.

By investing in high-quality mold pallets, infrastructure developers ensure that their projects are completed on time, within budget, and with minimal risk of failure or delays. With durable and precise pallets, contractors and manufacturers can rely on consistent, high-quality pipes for their long-term infrastructure needs.

In conclusion, ductile iron pipe mould pallets, along with stamping concrete pipe mold pallets and punching concrete pipe mold pallets, are integral to the efficient and effective production of pipes used in water and sewage systems. These products not only improve the quality of pipes but also contribute to the overall success of large-scale infrastructure projects. Their durability, precision, and cost-effectiveness make them an essential investment for manufacturers involved in the creation of reliable infrastructure. For wholesale purchasing options, our website offers high-quality pipe mold pallets to meet the demands of any project.

-

The Ultimate Choice for Optimal Thermal Exchange: Hex Heat Exchangers

ニュースJun.24,2025

-

Hydronic Gas Boiler: The Efficient Heating Solution For Your Needs

ニュースJun.24,2025

-

Discover the Efficiency of Mini Boiler Gas

ニュースJun.24,2025

-

Concrete Pipe Mold Pallet Solutions

ニュースJun.24,2025

-

Unveiling the Benefits of Light Pallet Mould

ニュースJun.24,2025

-

Discover the Benefits of Ductile Cast Iron Pipe Mold Pallet

ニュースJun.24,2025