- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

11月 . 25, 2024 23:59 Back to list

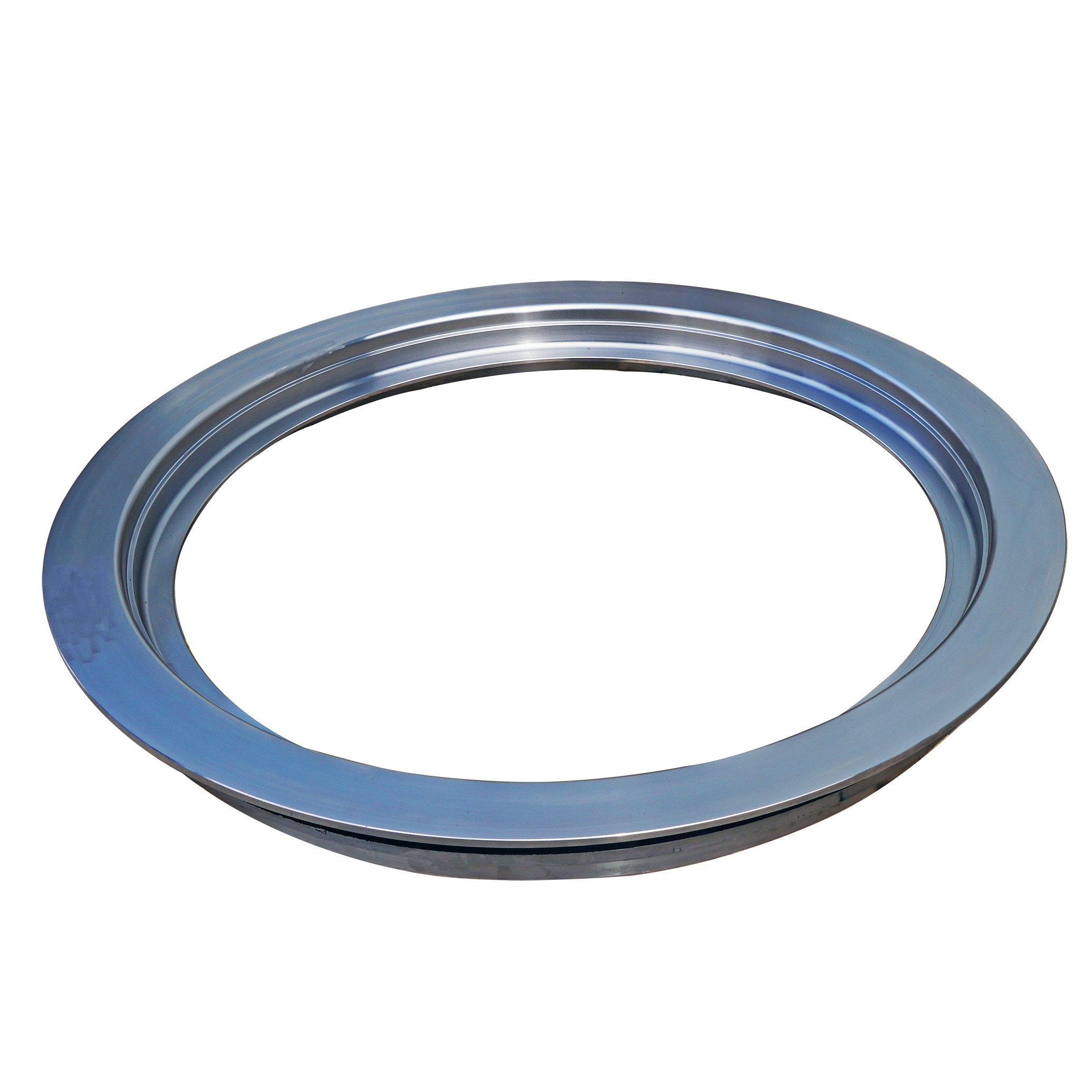

China Ductile Iron Pipe Mold Base Ring Specifications and Applications

Understanding the Importance of Ductile Iron Pipe Mold Bottom Rings in China

Ductile iron pipes have gained significant popularity in various water and wastewater applications due to their superior strength and durability. One of the critical components in the manufacturing process of these pipes is the mold, particularly the bottom ring of the mold. In China, the production of ductile iron pipe mold bottom rings is an essential aspect of the overall pipe manufacturing process.

The bottom ring of the ductile iron pipe mold plays a vital role in the shaping and forming of the pipe. It is responsible for maintaining the structural integrity of the mold during the pouring and cooling process of the molten iron. The quality of the bottom ring directly impacts the final product, influencing both the mechanical properties and the surface finish of the ductile iron pipes.

In China, the manufacturing of these bottom rings involves advanced technologies and materials to ensure high performance. Manufacturers employ various techniques, including precision casting and machining, to produce bottom rings that can withstand the rigorous conditions of pipe production. The usage of high-quality cast iron with excellent tensile strength ensures that the bottom rings can endure the weight of the molten iron and maintain the correct dimensions throughout the casting process.

china ductile iron pipe mold bottom ring

Moreover, the adoption of innovative designs and engineering practices allows Chinese manufacturers to improve the efficiency of mold production. By focusing on reducing wear and tear on the molds, they can extend the lifespan of the bottom rings and optimize production cycles. This not only results in cost savings for manufacturers but also enhances the overall quality of ductile iron pipes.

Environmental considerations play a crucial role in the manufacturing sector in China. Many companies are investing in greener technologies and processes to minimize their carbon footprint. This includes recycling scrap metal to produce ductile iron and using energy-efficient machinery in the production of mold bottom rings. Such practices contribute to sustainable development in the iron and steel industry, addressing global concerns about resource depletion and environmental degradation.

In conclusion, the ductile iron pipe mold bottom ring is a fundamental component in the pipe manufacturing process in China. Its production involves advanced techniques and materials aimed at optimizing strength, durability, and overall performance. With a focus on sustainability and efficiency, Chinese manufacturers are not only enhancing the quality of ductile iron pipes but also contributing to a greener future in industrial manufacturing.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025