- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

10月 . 18, 2024 09:27 Back to list

China Investment Casting Part Manufacturers for Quality Components and Reliable Supply

Understanding the Role of China Investment Casting Part Suppliers

In recent years, the global manufacturing landscape has seen a dramatic shift, with China emerging as a leading supplier of various components. Among the various production techniques employed, investment casting stands out as a highly efficient method used to create complex shapes with excellent dimensional accuracy and surface finish. This article explores the significance of investment casting part suppliers in China, highlighting the advantages and challenges involved in sourcing these components.

What is Investment Casting?

Investment casting, often referred to as lost-wax casting, is a manufacturing process that involves creating a wax pattern of the desired part, coating it with a ceramic material, and then melting away the wax to leave a cavity for molten metal. This process allows for intricate designs and is suitable for producing components with fine details, thin walls, and tight tolerances. It's particularly popular in industries like aerospace, automotive, and medical devices, where precision is critical.

The Advantages of Sourcing from China

1. Cost-Effectiveness One of the most significant advantages of sourcing investment casting parts from China is the cost savings. Chinese manufacturers benefit from lower labor costs and economies of scale, enabling them to offer competitive pricing without compromising quality.

2. High Production Capacity China has invested heavily in advanced manufacturing technologies and infrastructure. This investment means that suppliers are often equipped to handle large volumes of orders, meeting both small-scale and mass production needs efficiently.

3. Skilled Workforce The country boasts a well-trained workforce skilled in engineering and manufacturing processes. This expertise ensures that Chinese suppliers can produce high-quality investment casting parts that adhere to international standards.

4. Diverse Material Options Chinese suppliers typically provide a broad range of materials for investment casting, including steel, aluminum, copper, and even specialty alloys. This diversity allows clients to select the most appropriate material for their specific application.

china investment casting part suppliers

5. Rapid Prototyping The ability to produce prototypes rapidly is another key benefit. Many suppliers offer quick turnaround times for prototypes, enabling companies to test designs and make necessary adjustments before committing to larger production runs.

Challenges of Sourcing from China

Despite the numerous benefits, there are challenges associated with sourcing investment casting parts from China

1. Quality Control Maintaining consistent quality can be a concern, particularly when working with multiple suppliers. It is crucial for companies to implement stringent quality control measures and conduct regular inspections to ensure that the products meet the required specifications.

2. Communication Barriers Language and cultural differences may pose challenges in communication. Businesses must ensure that they effectively convey their requirements and expectations to avoid misunderstandings.

3. Long Lead Times While many Chinese suppliers are efficient, lead times can still be longer than those of local suppliers, particularly for complex parts requiring significant setup or tooling. Businesses should factor in these lead times when planning their production schedules.

4. Intellectual Property Concerns Protecting intellectual property (IP) can be a significant issue when working with overseas suppliers. Companies should take appropriate legal measures to safeguard their designs and proprietary information.

Conclusion

Investment casting part suppliers in China play a vital role in the global manufacturing supply chain. The combination of cost-effectiveness, high production capacity, and diverse material selections makes China an attractive option for companies looking to source precision components. However, it’s essential for businesses to navigate the potential challenges, ensuring that they maintain quality and protect their intellectual property. As industries continue to evolve and demand for precision components increases, the partnership with reliable investment casting suppliers in China will likely become even more crucial.

-

Custom Cast Silicon Aluminum Heat Exchangers for Hot Water Boilers

NewsJun.02,2025

-

Stainless Steel Impellers - Custom & Durable Solutions ODM Available

NewsJun.02,2025

-

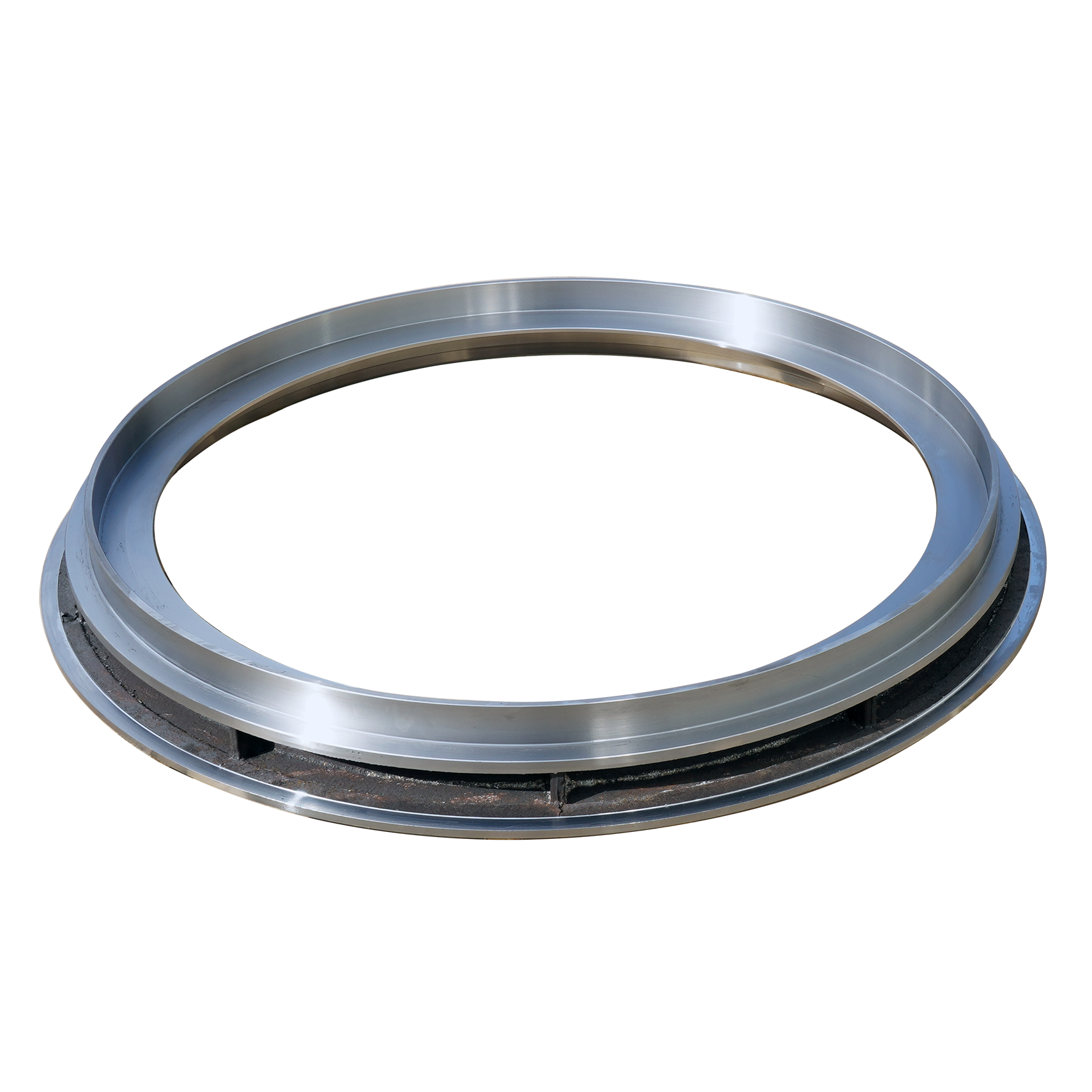

Stamping Concrete Pipe Mold Bottom Ring Custom & Durable Solutions

NewsJun.02,2025

-

Custom Furniture Hardware Durable & Affordable Solutions Shop Now

NewsJun.01,2025

-

SRC Concrete Pipe Bottom Ring Durable & Customizable Solutions

NewsJun.01,2025

-

Machine Base Casting Solutions Custom & ODM Precision Castings

NewsMay.31,2025