- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ოქტ . 07, 2024 01:17 Back to list

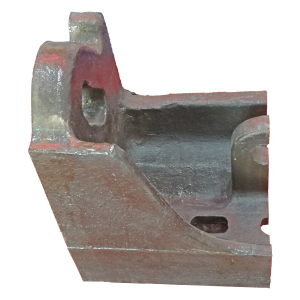

casting part manufacturer

The Role of Casting Part Manufacturers in Modern Industries

In the contemporary industrial landscape, the importance of casting part manufacturers cannot be overstated. These manufacturers play a critical role in producing intricate components used across various sectors, including automotive, aerospace, construction, and machinery. Casting is a versatile and cost-effective manufacturing process that involves pouring molten metal into a mold to create parts with complex shapes and sizes. This article explores the significance of casting part manufacturers, the processes involved, and their impact on different industries.

Casting part manufacturers utilize a range of techniques, including sand casting, investment casting, and die casting, to meet the diverse needs of their clients. Sand casting, one of the oldest and most commonly used methods, involves creating a mold from sand and pouring molten metal into it. This technique is ideal for producing large parts and low-volume production runs. In contrast, investment casting is favored for producing high-precision components in industries where tolerances are critical, such as aerospace and medical devices. Die casting, which involves forcing molten metal into a steel mold under pressure, is primarily used for producing high-volume parts with excellent surface finish and dimensional accuracy.

The growth of casting part manufacturers is closely linked to advancements in technology. With the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM), manufacturers can design and simulate casting processes more effectively than ever before. This not only enhances efficiency but also allows for the optimization of designs to reduce material waste and improve sustainability. Furthermore, the adoption of 3D printing in creating molds and patterns is revolutionizing the casting process, enabling faster prototyping and greater design flexibility.

casting part manufacturer

The impact of casting part manufacturers extends far beyond production. They contribute to the overall economy by creating jobs and supporting local businesses in the supply chain. As industries increasingly focus on reducing costs and improving product quality, casting part manufacturers must adopt innovative strategies to stay competitive. This includes investing in research and development to explore new materials, improving production techniques, and enhancing quality control measures.

Sustainability is another crucial aspect that casting part manufacturers are beginning to prioritize. With growing awareness of environmental issues, many manufacturers are exploring ways to minimize their carbon footprint. This includes using recycled materials in their casting processes and implementing energy-efficient practices to reduce waste and emissions.

In conclusion, casting part manufacturers are an integral part of the manufacturing ecosystem, providing essential components that drive innovation and efficiency across various industries. As technology continues to evolve and sustainability becomes a key focus, these manufacturers will undoubtedly play a pivotal role in shaping the future of manufacturing. By embracing advancements in technology and prioritizing environmentally friendly practices, casting part manufacturers can remain competitive and contribute to a more sustainable industrial landscape.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025