- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

დეკ . 06, 2024 12:08 Back to list

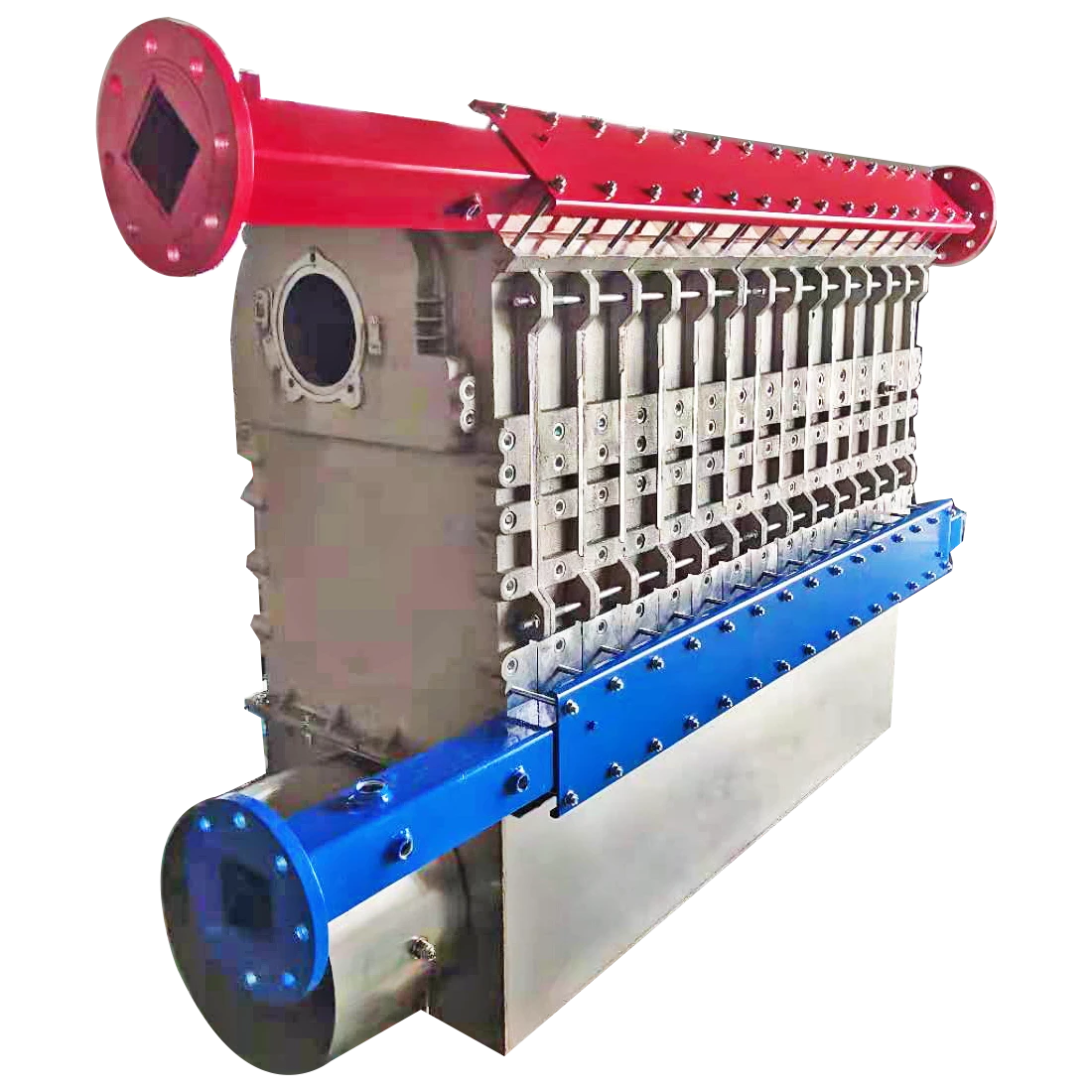

Custom Pressing Pipe Molds for Enhanced Pallet Production and Efficiency Solutions

The Evolution and Importance of OEM Pressing Pipe Mold Pallets

In today’s rapidly evolving manufacturing landscape, the demand for efficient and high-quality production processes has led to significant advancements in tooling and equipment. Among these innovations, OEM (Original Equipment Manufacturer) pressing pipe mold pallets have emerged as pivotal elements in the production of plastic and metal piping systems. These pallets not only streamline the production process but also ensure the consistent quality and precision needed in various industries, including construction, automotive, and plumbing.

Understanding OEM Pressing Pipe Mold Pallets

OEM pressing pipe mold pallets are specialized tools used to manufacture pipes through a pressing method. This process involves shaping materials like plastic and metals into precise forms for further use in various applications. The design of these pallets is intricately related to the type of pipe being produced, with factors such as size, shape, and material composition playing crucial roles.

The OEM aspect signifies that these pallets are designed and manufactured in accordance with the specifications and requirements of specific clients or industries. This tailored approach allows for enhanced compatibility with existing production lines and ensures that the molds can handle specific production needs, leading to improved efficiency and reduced waste.

The Production Process

The manufacturing process of a pressing pipe mold pallet typically starts with high-quality raw materials. Steel, aluminum, and various alloys are commonly used due to their durability and ability to withstand high pressure and temperature. Once the materials are sourced, advanced techniques such as CNC (Computer Numerical Control) machining are employed to fabricate precise components.

After initial machining, the pallets undergo rigorous testing to ensure they meet stringent quality standards. This quality assurance process is essential, as any imperfections in the mold can lead to significant waste and inefficiencies during production. Once tested, the pallets are then coated or treated to enhance their lifespan and resist wear.

oem pressing pipe mold pallet

Advantages of Using OEM Pressing Pipe Mold Pallets

1. Customization One of the primary advantages of OEM pressing pipe mold pallets is their ability to be customized to meet the specific needs of a production line. This customization allows manufacturers to create unconventional pipe designs or to produce multiple pipe sizes without needing multiple sets of molds.

2. Increased Efficiency With these tailored pallets, manufacturing processes can see a reduction in cycle times. The precise shaping of the molds ensures that the production process flows smoothly, thereby increasing output.

3. Higher Quality Consistency is key in manufacturing. OEM pallets help maintain strict tolerances and product quality, ensuring that every pipe produced meets the required specifications. This is particularly critical in industries like plumbing and automotive, where safety and reliability are paramount.

4. Cost-Effectiveness Although the initial investment in OEM pallets may be higher than standard options, the longevity and efficiency of these molds often result in lower overall production costs. Reduced material waste and faster production times contribute to significant savings in the long term.

5. Innovative Designs The increasing demand for innovative and sustainable piping solutions has pushed manufacturers to rethink their designs. OEM pressing pipe mold pallets enable the exploration of new shapes and materials that can lead to more efficient use of resources.

Conclusion

As industries continue to grow and evolve, the importance of reliable and efficient manufacturing tools cannot be overstated. OEM pressing pipe mold pallets represent a crucial investment for manufacturers looking to enhance productivity while ensuring quality and customization in their piping solutions. With ongoing advancements in materials and technology, the future looks promising for OEM pallets, paving the way for innovations that will further revolutionize the pipe manufacturing industry. Quality, efficiency, and adaptability remain the cornerstones of manufacturing success, making these pallets indispensable tools in the modern production landscape.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025