- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Қаз . 11, 2024 03:13 Back to list

silicon aluminum alloy

The Significance of Silicon-Aluminum Alloys in Modern Engineering

Silicon-aluminum alloys have emerged as one of the most versatile and widely used materials in modern engineering. Their unique properties make them suitable for a variety of applications, ranging from aerospace and automotive industries to packaging and electronics. This article delves into the composition, properties, advantages, and applications of silicon-aluminum alloys, illustrating why they have become a staple in contemporary manufacturing.

Composition and Properties

Silicon-aluminum alloys are primarily formed by adding silicon to aluminum, typically in concentrations ranging from 5% to 20%. The addition of silicon enhances several properties of aluminum, making it more durable and versatile. These alloys can be categorized into two distinct types cast and wrought.

The cast silicon-aluminum alloys are notable for their excellent fluidity, making them ideal for casting processes. Thanks to their favorable solidification characteristics, they can be easily molded into complex shapes and thin-walled structures. On the other hand, wrought silicon-aluminum alloys are characterized by their enhanced mechanical properties, heat resistance, and corrosion resistance.

The microstructure of silicon-aluminum alloys, featuring a eutectic mixture of silicon and aluminum, results in superior mechanical performance, including improved tensile strength, ductility, and hardness. The presence of silicon not only lowers the melting point of aluminum but also reduces the risk of cracking during solidification, thereby enhancing the overall manufacturing process.

Advantages

One of the principal advantages of silicon-aluminum alloys is their lightweight nature combined with high strength-to-weight ratios. This makes them particularly appealing for industries looking to improve energy efficiency and reduce emissions. For instance, in the automotive sector, using lighter materials can lead to significant fuel savings and lower carbon footprints.

silicon aluminum alloy

Additionally, silicon-aluminum alloys exhibit excellent corrosion resistance and thermal stability. The ability to withstand extreme temperatures is crucial for applications in harsh environments, such as aerospace components that must endure fluctuating temperatures during flight.

The machinability of these alloys is another significant advantage. They can be easily machined, welded, and processed using various techniques, making them adaptable and efficient for manufacturing. Moreover, their excellent wear resistance and surface finish quality allow for the production of distinctively finished components, which is essential in consumer electronics and appliances.

Applications

The applications of silicon-aluminum alloys are vast and varied. In the automotive industry, these alloys are employed in engine blocks, cylinder heads, and transmission housings. Their lightweight nature and thermal conductivity contribute to improved engine performance and efficiency.

In aerospace engineering, silicon-aluminum alloys are utilized in structural components, aerospace frames, and aircraft skins, where every ounce of weight savings translates to operational efficiency and reduced fuel consumption. The transportation of goods is also enhanced by using silicon-aluminum alloys in packaging, as these materials can provide both strength and lightweight benefits.

The electronics sector capitalizes on the advantages of silicon-aluminum alloys by using them in heat sinks and casings, where thermal management is crucial. The ability to dissipate heat efficiently prolongs the lifespan of electronic devices and improves performance.

Conclusion

In summary, silicon-aluminum alloys exemplify the perfect blend of lightness, strength, and versatility, making them indispensable in various industries. As technology continues to advance, the demand for materials that can simultaneously provide performance and sustainability will only grow. Silicon-aluminum alloys are well-positioned to meet these challenges, contributing to innovations that enhance efficiency, reduce environmental impacts, and improve the quality of modern life. The ongoing research and development in this field promise even more breakthroughs, ensuring that silicon-aluminum alloys will remain a cornerstone of engineering materials for years to come.

-

Casting Bollards for Sale - Custom & ODM Solutions

NewsMay.08,2025

-

Custom Commercial Hot Water Heat Exchangers High-Efficiency & Durable

NewsMay.08,2025

-

Premium Casting Parts Supplier - Custom Grey Iron, Stainless Steel & Brass

NewsMay.07,2025

-

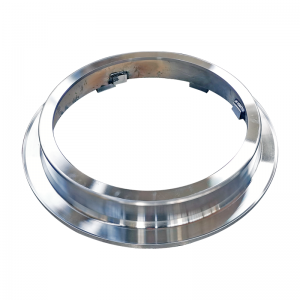

FRC Concrete Pipe Mold/Mould Bottom Ring Durable Precision Design

NewsMay.07,2025

-

Original Chinese Factory Supplier for Durable Concrete Pipe Mold Bottom Rings

NewsMay.07,2025

-

High-Strength Sodium Slicate Sand Casting Custom & ODM Services

NewsMay.07,2025