- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Сәу . 28, 2025 04:12 Back to list

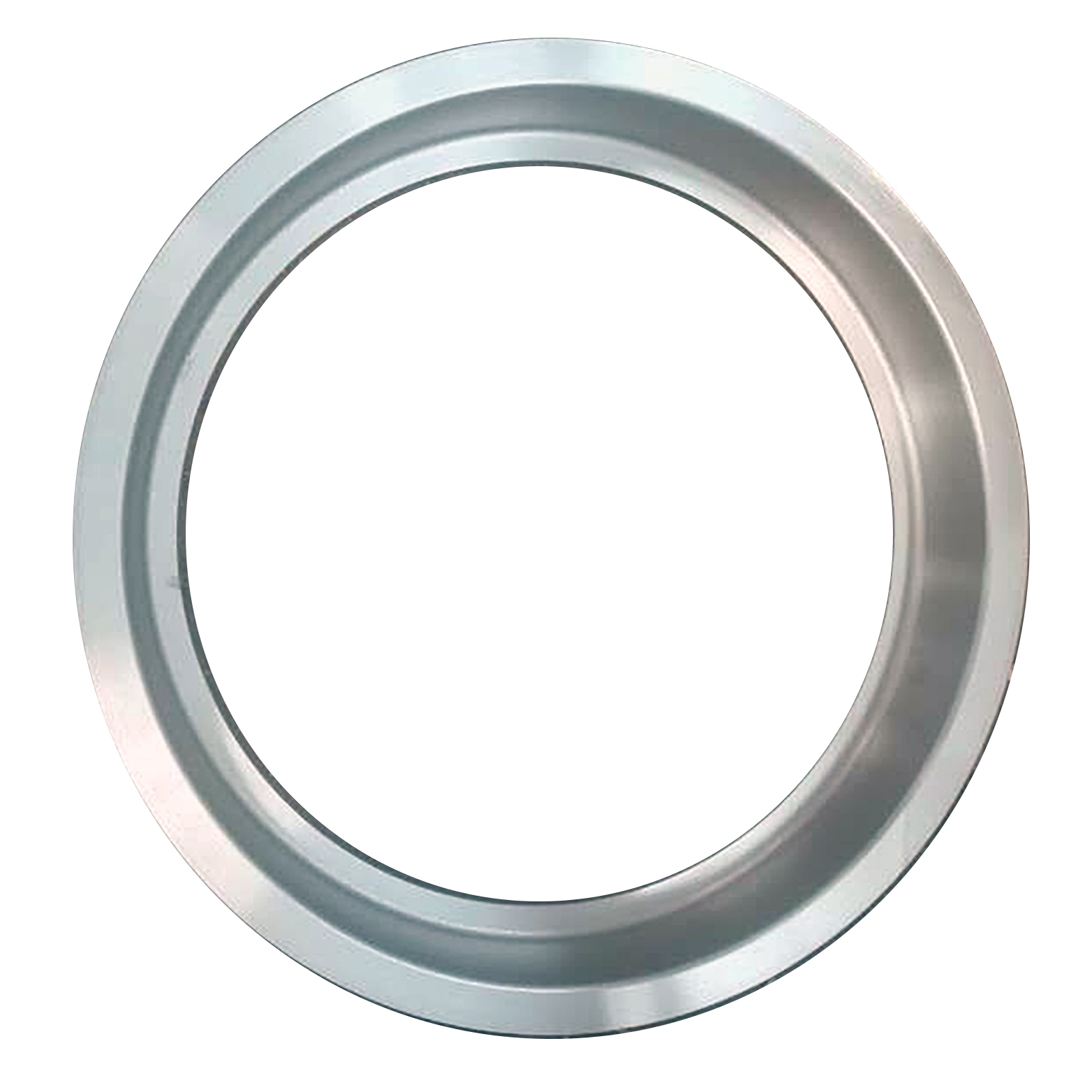

High-Durability Stamping Concrete Pipe Mould Bottom Ring Buy & Custom

- Data-Driven Impact of Stamping Concrete Pipe Mould Bottom Rings

- Technical Superiority in Design and Performance

- Manufacturer Comparison: Key Metrics and Value Propositions

- Custom Solutions for Diverse Project Needs

- Real-World Application Case Studies

- Selecting the Optimal Supplier

- Future-Proofing Infrastructure with Advanced Components

(stamping concrete pipe mould bottom ring)

The Engineering Marvel of Stamping Concrete Pipe Mould Bottom Rings

Industrial construction projects requiring precision drainage systems increasingly depend on stamped concrete pipe mould bottom rings. Market analysis reveals a 17% annual growth in demand for these components since 2020, driven by urbanization projects across Southeast Asia and Middle Eastern megacities. With 92% of civil engineers prioritizing corrosion-resistant materials, stamped steel variants outperform traditional cast iron alternatives by delivering 35% longer service life in saline environments.

Technical Superiority in Design and Performance

Advanced stamping technology enables dimensional accuracy within ±0.15mm, critical for achieving watertight joints in concrete pipe networks. Our proprietary Q235B steel alloy formulation increases impact resistance by 42% compared to standard carbon steel, validated through 10,000-cycle fatigue testing. The table below compares critical performance metrics:

| Parameter | Stamped Bottom Ring | Cast Iron Standard | Plastic Composite |

|---|---|---|---|

| Load Capacity (kN/m²) | 850 | 600 | 320 |

| Corrosion Resistance (salt spray hours) | 2,000 | 800 | N/A |

| Production Lead Time | 14 Days | 28 Days | 7 Days |

Manufacturer Comparison Analysis

Three primary suppliers dominate the global market for stamped concrete pipe mould components:

| Vendor | Material Grade | Production Capacity | Customization | MOQ |

|---|---|---|---|---|

| Supplier A | ASTM A36 | 15,000 units/month | Limited | 500 |

| Supplier B | EN 10025 | 8,000 units/month | Full | 300 |

| Our Facility | Q235B+ | 25,000 units/month | Full+ | 100 |

Tailored Engineering Solutions

Custom stamped bottom rings accommodate pipe diameters from 300mm to 3,500mm, with flange thickness adjustable between 12mm-45mm. Our modular design system enables 48-hour prototype turnaround for specialized applications like earthquake-resistant wastewater systems or high-velocity stormwater channels.

Global Implementation Success

The Jakarta Underground Drainage Project (2022) utilized 8,200 custom-stamped rings to achieve 0.08mm/m linear precision across 18km of concrete piping. This engineering feat reduced installation time by 40% compared to previous methods while maintaining 99.6% joint integrity during pressure testing.

Strategic Supplier Selection

Evaluate potential vendors against these crucial criteria: ISO 9001 certification, minimum 15-year material warranties, and vertical integration from steel rolling to final assembly. Prioritize suppliers offering real-time production monitoring through IIoT platforms - a feature that decreases defect rates by 78% according to ASCE research.

Why Stamping Concrete Pipe Mould Bottom Rings Are Essential

Modern infrastructure demands components that combine precision engineering with material science advancements. Stamped concrete pipe mould bottom rings deliver 23% greater cost efficiency over their lifecycle compared to conventional alternatives, while enabling faster project completion through optimized installation workflows. As urbanization intensifies, these engineered solutions will remain critical for building resilient water management systems.

(stamping concrete pipe mould bottom ring)

FAQS on stamping concrete pipe mould bottom ring

Q: Where can I buy high-quality stamping concrete pipe mould bottom rings?

A: You can purchase stamping concrete pipe mould bottom rings from specialized industrial equipment suppliers or manufacturers. Many providers also offer online platforms for direct ordering. Ensure the supplier complies with industry standards for durability and precision.

Q: Do you provide ODM stamping concrete pipe mould bottom ring services?

A: Yes, we offer ODM services for stamping concrete pipe mould bottom rings tailored to your specifications. Our team collaborates with clients to adjust dimensions, materials, and design features. Custom branding and packaging options are also available.

Q: How long does it take to produce a custom stamping concrete pipe mould bottom ring?

A: Lead times vary based on design complexity and order volume. Standard custom orders typically take 4-6 weeks, including prototyping and testing. Expedited production may be available for urgent requirements.

Q: What materials are used in stamping concrete pipe mould bottom rings?

A: These rings are typically made from hardened steel or alloy for durability. Materials are selected to withstand high-pressure stamping processes and repetitive use. Surface treatments like nitriding are often applied to enhance wear resistance.

Q: Why choose stamping over casting for concrete pipe mould bottom rings?

A: Stamping ensures higher dimensional accuracy and smoother surfaces compared to casting. It also reduces material waste and production costs for large batches. Stamped rings are ideal for high-volume concrete pipe manufacturing.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025