- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Қар . 08, 2024 16:53 Back to list

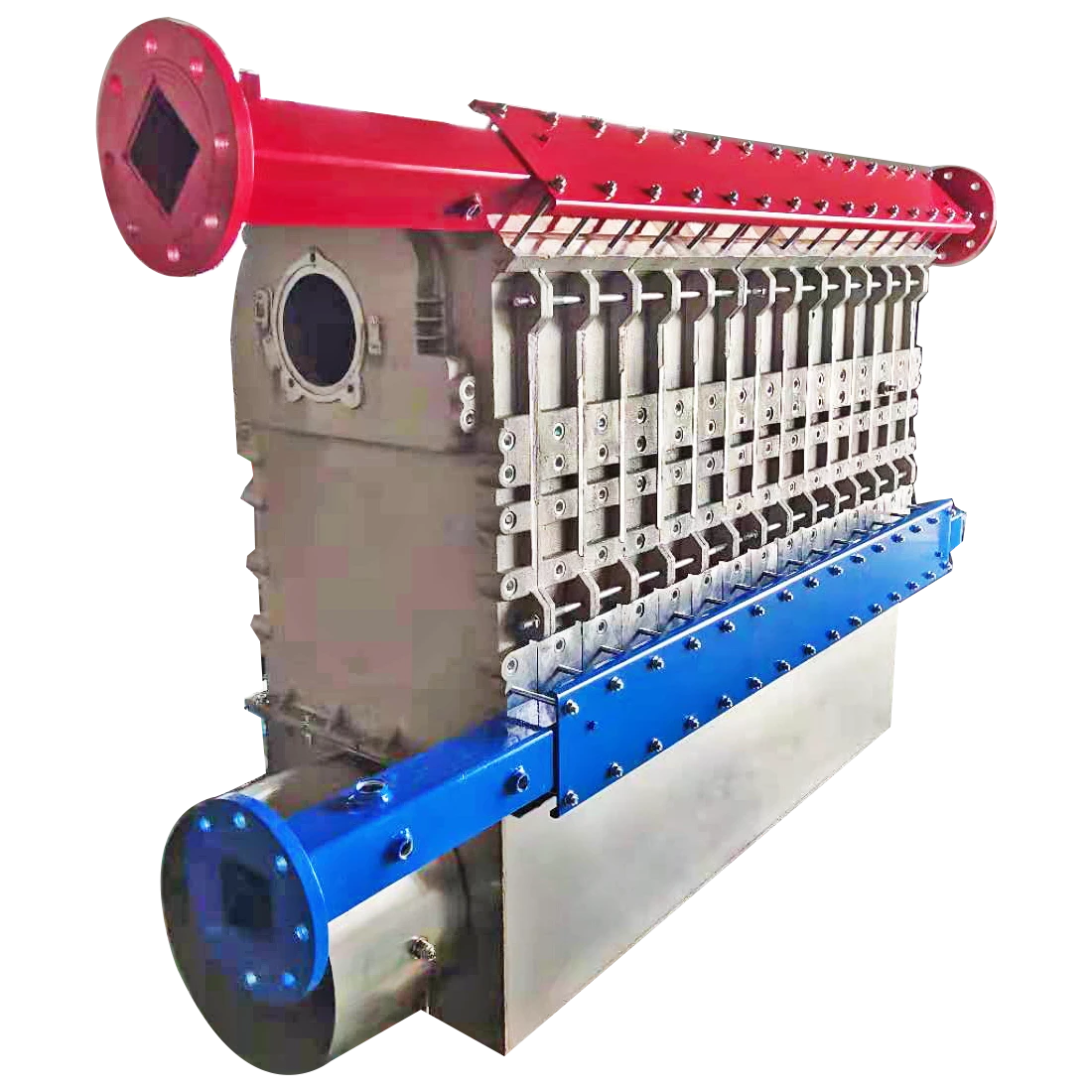

wholesale investment castings

The Significance of Wholesale Investment Castings in Modern Manufacturing

In the contemporary landscape of manufacturing, wholesale investment castings have emerged as a pivotal method for producing high-quality metal components. This process, renowned for its precision and versatility, plays an essential role across various industries, including aerospace, automotive, medical devices, and energy. In this article, we will explore the characteristics, advantages, and impact of wholesale investment castings on manufacturing.

Understanding Investment Casting

Investment casting, also known as lost-wax casting, is a method that involves creating a wax model of the desired part. The model is coated in a ceramic material, which is then heated to remove the wax, leaving a detailed mold. Molten metal is then poured into this mold to create the final product. The precision and intricacy of this technique allow manufacturers to produce complex geometries that would be challenging, if not impossible, to achieve with traditional machining methods.

Benefits of Wholesale Investment Castings

1. Precision and Detail One of the most significant advantages of investment casting is its ability to produce highly detailed components with tight tolerances. This precision is crucial in industries such as aerospace, where even the slightest deviation can lead to critical failures.

2. Material Versatility Investment casting can accommodate a wide variety of metals, including stainless steel, aluminum, brass, and special alloys. This versatility enables manufacturers to select the most suitable material for their products, ensuring optimal performance and longevity.

3. Cost-Efficiency for Large Volumes While the initial setup for investment casting can be higher than other methods, it becomes cost-effective for large-scale production. Once the mold is created, each additional casting incurs minimal incremental costs, making it an economical choice for bulk manufacturing.

4. Reduced Waste Traditional machining often produces significant material waste as excess stock is cut away. In contrast, investment casting is a net-shape process, meaning that it uses only the material required to create the part. This reduction in waste not only lowers costs but also supports environmentally sustainable manufacturing practices.

5. Strength and Integrity Investment cast parts generally exhibit superior mechanical properties due to the uniformity in their structure. This ensures that the final components are not only dimensionally accurate but also resistant to wear and tear, making them ideal for critical applications.

wholesale investment castings

Applications Across Industries

The versatility of wholesale investment castings allows their application across diverse fields

.- In the aerospace industry, components such as turbine blades and airframes benefit from the precision and lightweight characteristics achieved through investment casting.

- The automotive sector also extensively uses investment castings for engine parts, transmission housings, and chassis components, where reliability and performance are paramount.

- In the medical device industry, surgical instruments and implants produced via investment casting meet stringent regulatory requirements for safety and efficacy.

- Additionally, the energy sector, particularly in the manufacture of turbine components for wind and gas power, relies on the strength and durability provided by investment castings.

The Future of Wholesale Investment Castings

As industries continue to evolve, the demand for high-quality, complex metal components is only set to increase. Technological advancements, such as 3D printing and improved alloy formulations, are likely to enhance the capabilities of investment casting. Furthermore, as sustainability becomes a focal point in manufacturing, the waste reduction and efficiency offered by investment casting will align well with these goals.

In conclusion, wholesale investment castings represent a cornerstone of modern manufacturing, offering unparalleled precision, material versatility, and efficiency. As technology continues to progress and industries seek to innovate, investment casting will undoubtedly play a crucial role in shaping the future of manufacturing. Whether one is producing components for airplanes or everyday consumer products, the advantages of this casting method are significant, making it an essential consideration in the design and manufacturing process.

-

Custom Furniture Hardware Supplies Buy Durable Parts Online

NewsMay.30,2025

-

Custom & ODM Stamp Concrete Pipe Mold Pallets Durable Solutions

NewsMay.30,2025

-

Buy Custom Steel Reinforced Concrete Pipe Bottom Rings & Moulds

NewsMay.30,2025

-

Low NOx Condensing Gas Boilers for Commercial Heating High Efficiency

NewsMay.29,2025

-

Custom & ODM Cast Steel Pipe Mould Bottom Ring Suppliers

NewsMay.29,2025

-

Custom Ductile Iron Pipe Mold Pallets High Durability & Order Now

NewsMay.29,2025