ធ្នូ . 04, 2024 16:43 Back to list

Exporter Specializing in Casting Parts for Various Industries and Applications

The Growing Importance of Casting Parts Exporters in Global Trade

In today's interconnected global economy, casting parts exporters play a crucial role in manufacturing and supply chains across a multitude of industries. Casting, a process that involves pouring molten metal into molds to create precise components, is essential for producing parts used in everything from automotive and aerospace applications to machinery and consumer goods. As demand for high-quality cast components increases worldwide, the role of casting parts exporters becomes ever more significant.

One of the primary reasons for the growth of casting parts exporters is the rise of globalization. Companies are constantly seeking ways to reduce production costs and improve efficiency. By sourcing casting parts from specialized exporters, manufacturers can benefit from cost-effective solutions without compromising quality. Countries like China, India, and Brazil have emerged as key players in this sector, offering competitive prices and a wide range of capabilities. These nations possess the necessary infrastructure and labor force to produce casting parts at scale, making them attractive partners for businesses in developed countries.

Moreover, the advancement of technology has transformed the casting industry, leading to improved production methods and higher quality standards. Continuous innovations in materials science, computer-aided design, and manufacturing processes have allowed exporters to offer products that meet stringent specifications. For example, the use of 3D printing in the casting process has enabled the production of complex geometries that were previously impossible to achieve, thereby opening new markets and opportunities for exporters.

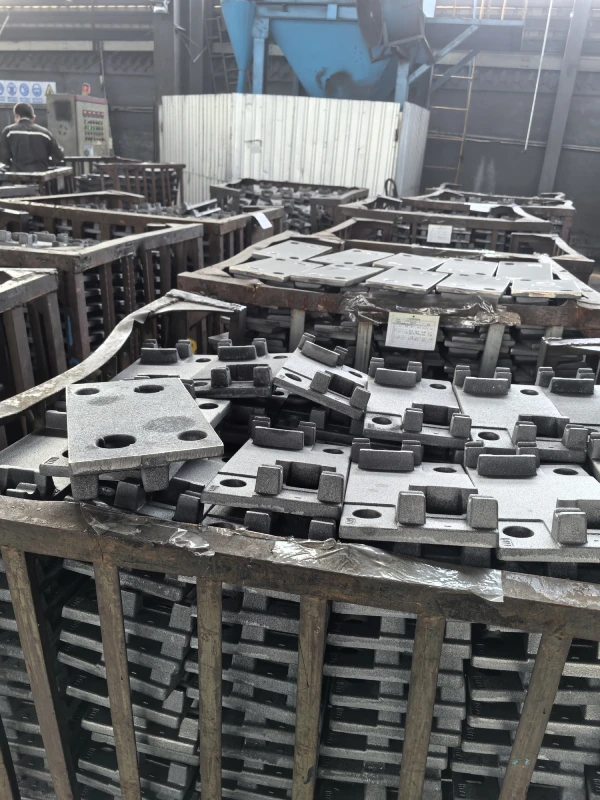

casting parts exporter

The automotive industry is one of the largest consumers of casting parts, relying on them for engine blocks, transmission cases, and other critical components. With the rise of electric vehicles (EVs), there is a growing demand for lightweight and durable casting solutions that enhance vehicle performance and energy efficiency. Casting parts exporters are innovating in this area, providing materials that meet the unique requirements of EV manufacturers while ensuring sustainability. Companies are increasingly focused on creating eco-friendly materials and processes, highlighting the importance of corporate responsibility within the casting parts export sector.

Another factor contributing to the success of casting parts exporters is the growing trend of custom and small-batch production. Many manufacturers are shifting away from mass production to focus on creating tailored solutions for niche markets. This shift necessitates collaboration with exporters who can provide specialized casting solutions that cater to specific client needs. As a result, casting parts exporters are developing more flexible manufacturing processes, enabling them to respond quickly to market changes and customer preferences.

However, the landscape of casting parts exporters is not without its challenges. Trade barriers, fluctuating tariffs, and geopolitical tensions can affect the movement of goods and create uncertainties in the supply chain. Additionally, exporters must navigate varying regulations and standards in different countries to ensure compliance and maintain a competitive edge. As such, adaptability and strategic foresight are critical skills for casting parts exporters to thrive in the global market.

In conclusion, casting parts exporters serve as a vital link in the global manufacturing chain, addressing the growing demand for high-quality, cost-effective solutions. Their role extends beyond mere trade; they are key players in driving innovation, promoting sustainability, and supporting the evolution of industries worldwide. As globalization continues to shape the business landscape, the significance of casting parts exporters will only continue to grow, making them integral to the future of manufacturing.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025