- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កញ្ញា . 10, 2024 07:19 Back to list

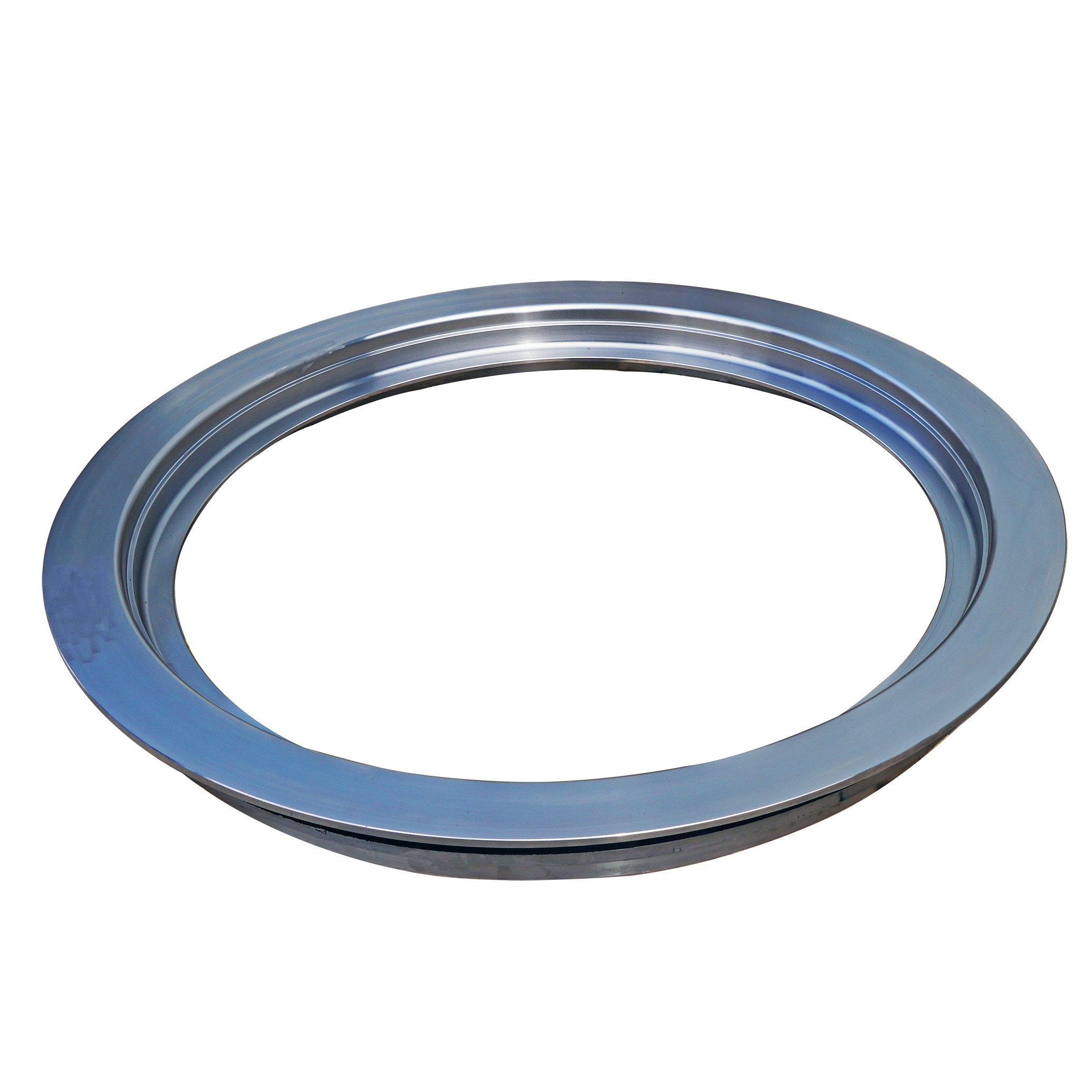

China Metal Sand Casting - High Quality Custom Foundry Services

China’s Metal Sand Casting An Overview

Metal sand casting is a pivotal manufacturing process in China, playing a crucial role in various industries, including automotive, aerospace, and machinery. This traditional yet highly adaptive technique allows for the production of complex metal parts and components with relative efficiency. As China's industrial landscape continues to evolve, the significance of metal sand casting remains robust, contributing to both domestic needs and global supply chains.

The Process of Metal Sand Casting

The process of sand casting involves several key steps. First, a mold is created using a pattern, which is typically made from metal, wood, or plastic. The pattern is placed into sand, which is then compacted to form a mold that is an exact replica of the desired part. Once the mold is ready, molten metal is poured into it. The sand’s temperature resistance makes it ideal for this purpose, as it can withstand the heat of the molten metal.

After the metal cools and solidifies, the mold is broken apart to extract the cast part. This process can be repeated with variations in the mold design or metal composition to produce different components. In China, the materials used for casting range from ferrous metals like cast iron and steel to non-ferrous metals like aluminum and bronze, allowing manufacturers to select the best material for specific applications.

Advantages of Sand Casting

One of the primary advantages of sand casting is its versatility. The method can be used to create intricate designs that would be difficult or impossible to achieve with other manufacturing techniques. Furthermore, sand casting is cost-effective for producing small to medium-sized batches, making it particularly appealing for companies looking to produce custom parts.

china metal sand casting

In addition, metal sand casting allows for the use of a variety of metals, which provides manufacturers in China with a competitive edge. The ability to work with different alloys enables them to tailor products according to customer specifications, which is increasingly important in global markets.

Challenges and Innovations

Despite its advantages, metal sand casting in China faces several challenges. The global push for sustainability means that manufacturers must find ways to reduce waste and energy consumption in their processes. Additionally, competition from other manufacturing techniques, such as die casting and 3D printing, is on the rise, demanding innovation and adaptability from traditional sand casting operations.

To address these challenges, many Chinese companies are investing in research and development to enhance their sand casting processes. Innovations in mold materials, automation, and simulation technologies are streamlining production and improving efficiency. For instance, the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) in the design phase is allowing for more precise molds that increase the quality of the final product.

Conclusion

Metal sand casting remains a fundamental part of China’s manufacturing sector. The combination of traditional techniques with modern innovations is not only keeping this sector relevant but also positioning Chinese manufacturers for future growth. As the world increasingly looks to China for high-quality metal components, the resilience and adaptability of its sand casting processes will undoubtedly continue to play a central role in shaping the future of manufacturing on a global scale.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025