- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ធ្នូ . 12, 2024 10:40 Back to list

china investment casting factory

The Emergence of China’s Investment Casting Factories A Boon for Global Industry

In recent years, China has solidified its position as a global manufacturing powerhouse, particularly in the realm of investment casting. This process, also known as lost-wax casting, involves creating metal parts with exceptional precision and intricate designs. As industries increasingly turn to specialized components – from aerospace to automotive – China's investment casting factories have emerged as vital players in meeting this demand.

Understanding Investment Casting

Investment casting is a versatile manufacturing technique known for producing complex geometries with high precision. The process begins with creating a wax model of the desired part, which is then coated in a ceramic material to form a mold. Once the mold is hardened, the wax is melted away, leaving a cavity for molten metal to be poured in. This method allows manufacturers to create parts with intricate shapes and fine surface finishes, reducing the need for additional machining and maximizing material usage.

The Advantages of China’s Investment Casting Sector

China's investment casting factories have thrived due to several advantages. One of the most significant factors is cost efficiency. Labor prices in China are comparatively lower than in many Western countries, allowing for reduced manufacturing costs. In addition, the robust supply chain network facilitates easier access to raw materials, further driving down expenses.

Furthermore, China has witnessed substantial investments in advanced technology and machinery. Many factories are equipped with state-of-the-art equipment that enhances production capabilities. Automated systems, CNC machining centers, and advanced quality control processes ensure that the components produced meet international standards, enhancing the reliability of Chinese products in global markets.

Meeting Global Demand

The global demand for investment casting continues to rise across various sectors. The aerospace industry, for example, requires lightweight yet durable components. Investment casting is ideally suited to create intricate parts like turbine blades and structural components, which must withstand extreme conditions while minimizing weight. The automotive sector also relies on investment casting for high-performance parts, ensuring safety and efficiency in vehicle production.

china investment casting factory

China’s factories have positioned themselves not only to meet local demand but also to serve international markets. Many companies have established partnerships with foreign enterprises, leading to a significant increase in export activities. The ability to provide high-quality components at competitive prices has made Chinese investment casting factories a preferred choice for businesses worldwide.

Quality Assurance and Certification

While cost and efficiency are crucial, quality remains paramount in investment casting. Chinese factories have increasingly adopted international quality standards such as ISO 9001 and AS9100, particularly for industries like aerospace and automotive that demand stringent adherence to safety and performance specifications. Rigorous quality control measures, including X-ray inspection and non-destructive testing, are employed to ensure that every component produced meets the necessary criteria.

Additionally, many factories are focusing on sustainability practices. With growing global emphasis on environmental responsibility, some investment casting operations in China are implementing green manufacturing processes and waste recycling initiatives, thus appealing to environmentally conscious consumers.

Challenges and Future Outlook

Despite the successes, China's investment casting industry faces challenges. Intellectual property concerns and trade tensions with Western nations can complicate international collaborations. Additionally, as global competitors improve their capabilities, China must continue to innovate and enhance its production methods.

Looking ahead, the potential for growth in China's investment casting sector remains substantial. With advancements in technology and an ever-growing market demand, factories are poised to play a crucial role in the evolution of sectors relying on precision metal components. Investing in research and development will enable Chinese factories to remain at the cutting edge of the industry, catering to the evolving needs of global customers.

In conclusion, China's investment casting factories represent a significant segment of the global manufacturing landscape. Their combination of cost-effectiveness, advanced technology, and commitment to quality positions them well for continued success. As industries around the world require increasingly sophisticated components, China’s role as a leader in investment casting is likely to grow even more prominent in the years to come.

-

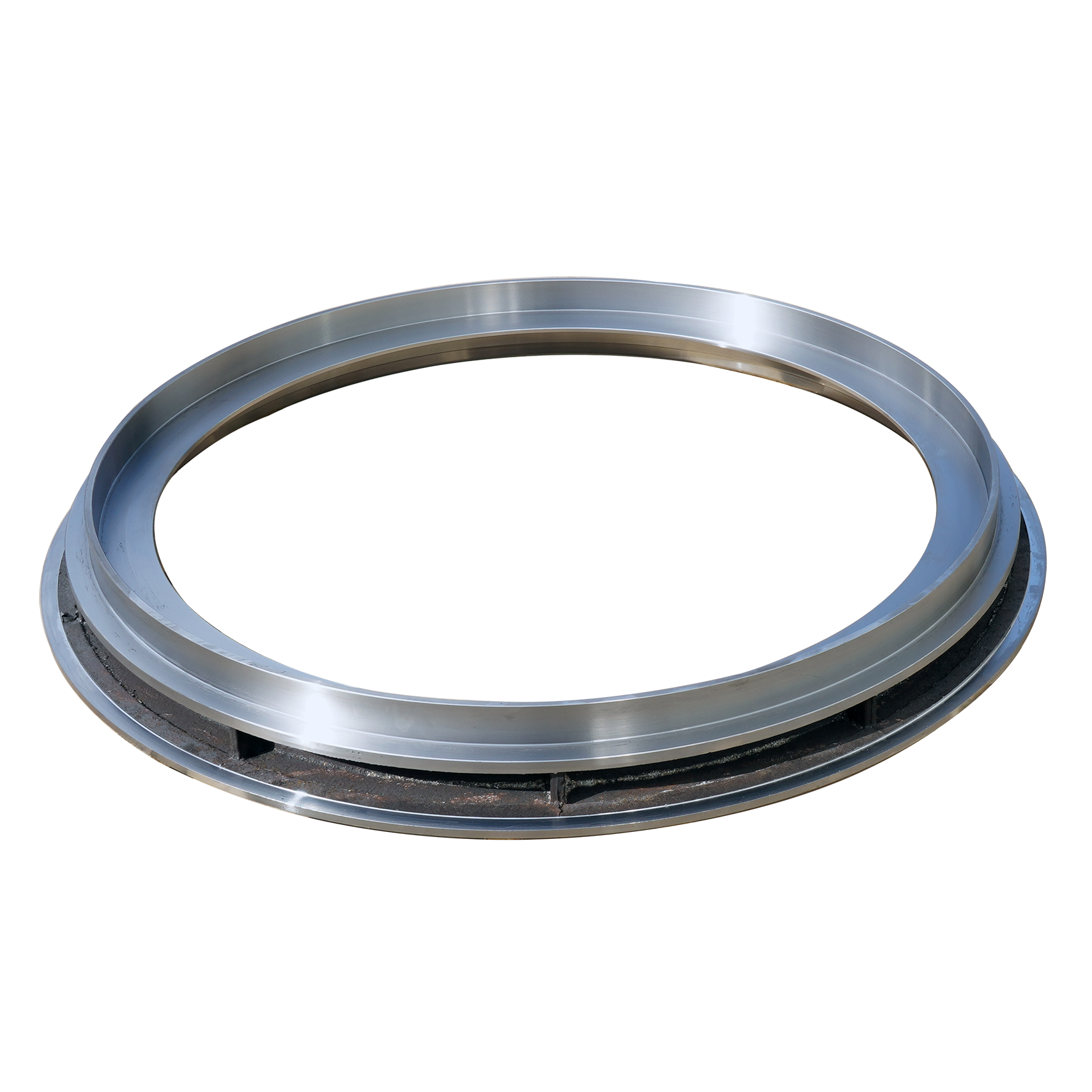

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025