- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ធ្នូ . 10, 2024 02:54 Back to list

Analysis of Cross Counterflow Heat Exchanger Performance and Design Considerations

Understanding Cross-Counter Flow Heat Exchangers

Heat exchangers are pivotal components in a variety of industrial applications, serving to transfer heat between two or more fluids without mixing them. Among the different configurations of heat exchangers, the cross-counter flow heat exchanger stands out due to its efficiency in thermal energy transfer. This article will delve into the principles, applications, advantages, and considerations of cross-counter flow heat exchangers.

What is a Cross-Counter Flow Heat Exchanger?

A cross-counter flow heat exchanger consists of two fluids flowing in opposite directions—one fluid flows horizontally while the other flows vertically. This configuration allows for a more efficient heat transfer compared to parallel flow or counterflow designs, making it a preferred choice in many industries.

Operating Principles

The fundamental principle behind heat exchangers is the second law of thermodynamics, which states that heat naturally flows from a higher temperature to a lower temperature. In a cross-counter flow heat exchanger, the hot and cold fluids are arranged so that they flow across each other, keeping a temperature gradient throughout the entire length of the exchanger. This design ensures that the heat can be transferred effectively, maximizing the thermal exchange rate.

As the hot fluid moves across the cold fluid, it gradually loses heat, while the cold fluid absorbs that heat, resulting in a decrease in temperature on one side and an increase on the other. The effectiveness of this process can be influenced by various factors, including flow rates, temperature differences, and specific heat capacities of the fluids involved.

Advantages of Cross-Counter Flow Heat Exchangers

1. Higher Efficiency The primary advantage of cross-counter flow heat exchangers is their superior thermal efficiency. The opposing flow directions create an optimal temperature gradient, which enhances the heat transfer process, making it more effective than other configurations.

2. Compact Design These heat exchangers often require less surface area compared to parallel flow designs, leading to a more compact installation. This is particularly beneficial in applications where space is constrained.

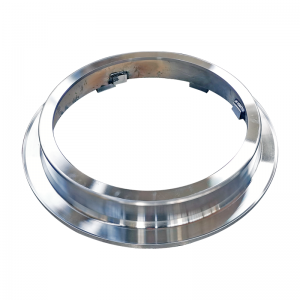

cross counter flow heat exchanger

3. Versatility Cross-counter flow heat exchangers can be employed in various scenarios, from industrial processes to HVAC systems, as they can handle a wide range of flow rates and fluid types.

4. Reduced Fouling The design of these heat exchangers helps to minimize the risk of fouling, a condition where deposits accumulate on the heat transfer surfaces, which can diminish performance.

5. Improved Heat Recovery They are particularly useful in applications focused on energy efficiency, such as waste heat recovery systems, where they can reclaim lost heat for reuse.

Applications

Cross-counter flow heat exchangers find applications in numerous sectors, including

- Chemical Processing Used to cool or heat reaction mediums where precise temperature control is essential. - Power Generation In power plants, they help in condensing steam, improving the overall thermal efficiency. - HVAC Systems Essential in heat recovery ventilators, where they transfer heat from outgoing air to incoming fresh air, enhancing energy efficiency. - Food and Beverage Industry Utilized in pasteurization processes and heat recovery systems, they help maintain product quality while optimizing energy usage.

Considerations and Challenges

While cross-counter flow heat exchangers offer numerous benefits, they also present certain challenges. The initial capital cost can be higher than other types, and suitable materials must be chosen to resist corrosion, especially when dealing with aggressive fluids. Additionally, maintenance might require careful planning due to the compact design, which can make access to certain parts difficult.

Conclusion

In summary, cross-counter flow heat exchangers are integral to efficient thermal management across various industries. Their design allows for optimal heat transfer performance, compactness, and versatility, making them a preferred solution in many applications. As industries continue to focus on energy efficiency and sustainability, the relevance and utility of cross-counter flow heat exchangers are only set to grow. Understanding their principles and applications will empower engineers and decision-makers to utilize these devices effectively for a more energy-efficient future.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025