កុម្ភៈ . 15, 2025 07:54 Back to list

Steel Casting Service

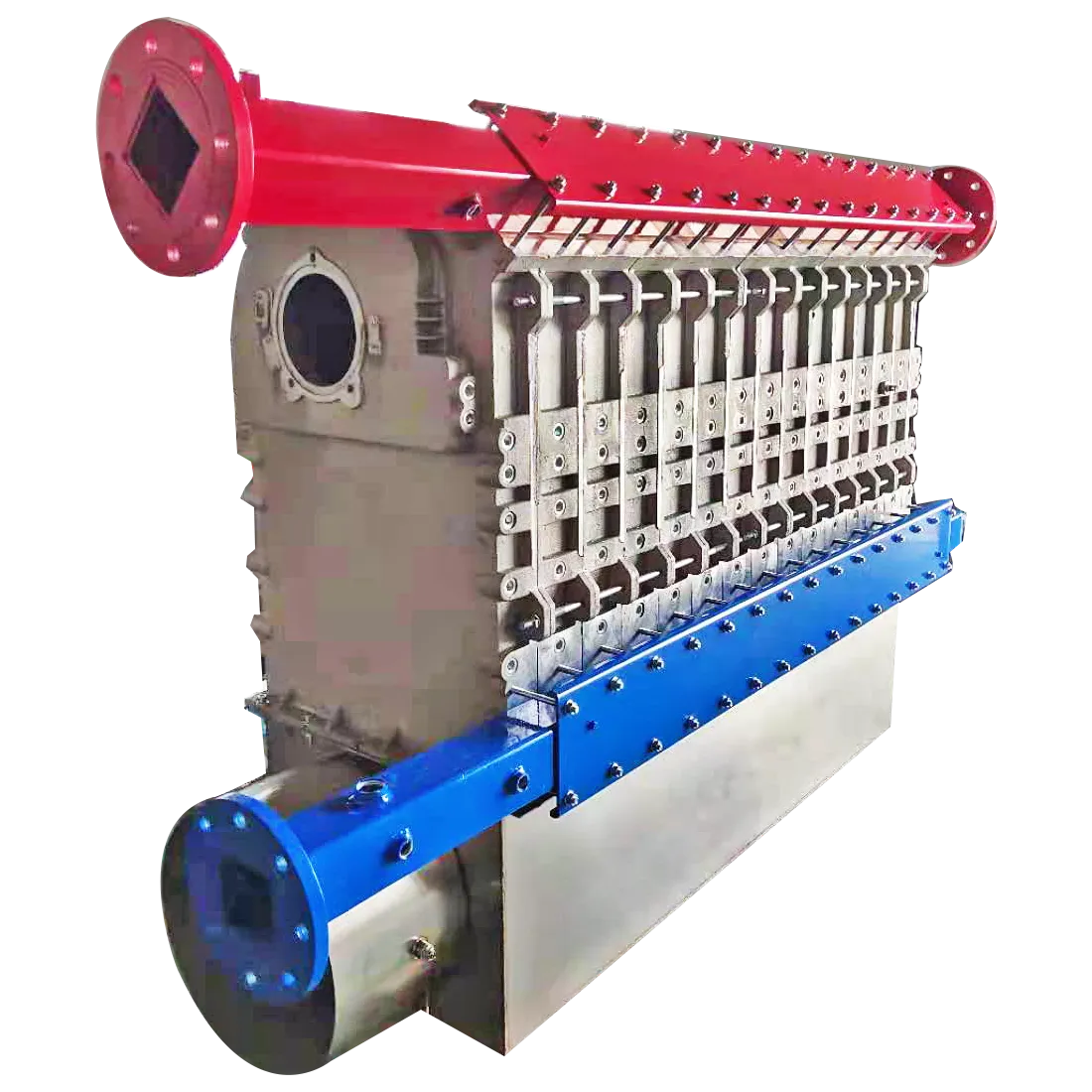

Double tube condensers stand as a pivotal component in various industrial applications, from chemical processing to HVAC systems. Understanding the intricacies of their operation, benefits, and maintenance can significantly enhance system efficiency and longevity, appealing to any expert or enthusiast in the field.

For those seeking to maximize the longevity and efficiency of their double tube condensers, regular maintenance is indispensable. Cleaning the tubes to prevent scaling and checking for leaks are fundamental aspects of prolongation. An unclean condenser can significantly compromise energy efficiency and increase operational costs. Therefore, adhering to a robust maintenance regime is crucial for sustaining optimal performance and reliability. Another aspect bolstering the appeal of double tube condensers is their energy efficiency. In an era where energy conservation is paramount, these condensers present a compelling case for sustainability. By improving the heat transfer efficiency, they contribute to less energy consumption, ultimately reducing the carbon footprint of industrial operations. However, selecting the right double tube condenser requires a comprehensive understanding of the specific requirements of your application. Factors such as the type of coolant used, available space, operating temperatures, and pressures must be carefully considered to ensure compatibility and efficiency. Consulting with a specialized engineer or technician can significantly aid in tailoring the condenser to meet precise needs. Furthermore, innovation continues to push the boundaries of what double tube condensers can achieve. Advances in materials science and fluid dynamics are progressively influencing their design and operation, paving the way for more compact, durable, and efficient models. Staying abreast of these technological developments can afford businesses a competitive edge by enabling them to incorporate the most cutting-edge solutions into their processes. In conclusion, double tube condensers are indispensable in numerous industries for their superior efficiency, flexibility, and durability. As the demand for more energy-efficient and sustainable technologies grows, these condensers will increasingly play a vital role in modern industrial applications. By blending expertise and experience, businesses can optimize their operations with double tube condensers, securing both economic and environmental benefits. Each choice regarding materials, design, and maintenance reflects both the authority and trustworthiness of a business, ensuring these components deliver robust performance over their lifespan.

For those seeking to maximize the longevity and efficiency of their double tube condensers, regular maintenance is indispensable. Cleaning the tubes to prevent scaling and checking for leaks are fundamental aspects of prolongation. An unclean condenser can significantly compromise energy efficiency and increase operational costs. Therefore, adhering to a robust maintenance regime is crucial for sustaining optimal performance and reliability. Another aspect bolstering the appeal of double tube condensers is their energy efficiency. In an era where energy conservation is paramount, these condensers present a compelling case for sustainability. By improving the heat transfer efficiency, they contribute to less energy consumption, ultimately reducing the carbon footprint of industrial operations. However, selecting the right double tube condenser requires a comprehensive understanding of the specific requirements of your application. Factors such as the type of coolant used, available space, operating temperatures, and pressures must be carefully considered to ensure compatibility and efficiency. Consulting with a specialized engineer or technician can significantly aid in tailoring the condenser to meet precise needs. Furthermore, innovation continues to push the boundaries of what double tube condensers can achieve. Advances in materials science and fluid dynamics are progressively influencing their design and operation, paving the way for more compact, durable, and efficient models. Staying abreast of these technological developments can afford businesses a competitive edge by enabling them to incorporate the most cutting-edge solutions into their processes. In conclusion, double tube condensers are indispensable in numerous industries for their superior efficiency, flexibility, and durability. As the demand for more energy-efficient and sustainable technologies grows, these condensers will increasingly play a vital role in modern industrial applications. By blending expertise and experience, businesses can optimize their operations with double tube condensers, securing both economic and environmental benefits. Each choice regarding materials, design, and maintenance reflects both the authority and trustworthiness of a business, ensuring these components deliver robust performance over their lifespan.

Share

Pervious:

Next:

Latest news

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025