- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

កញ្ញា . 22, 2024 09:04 Back to list

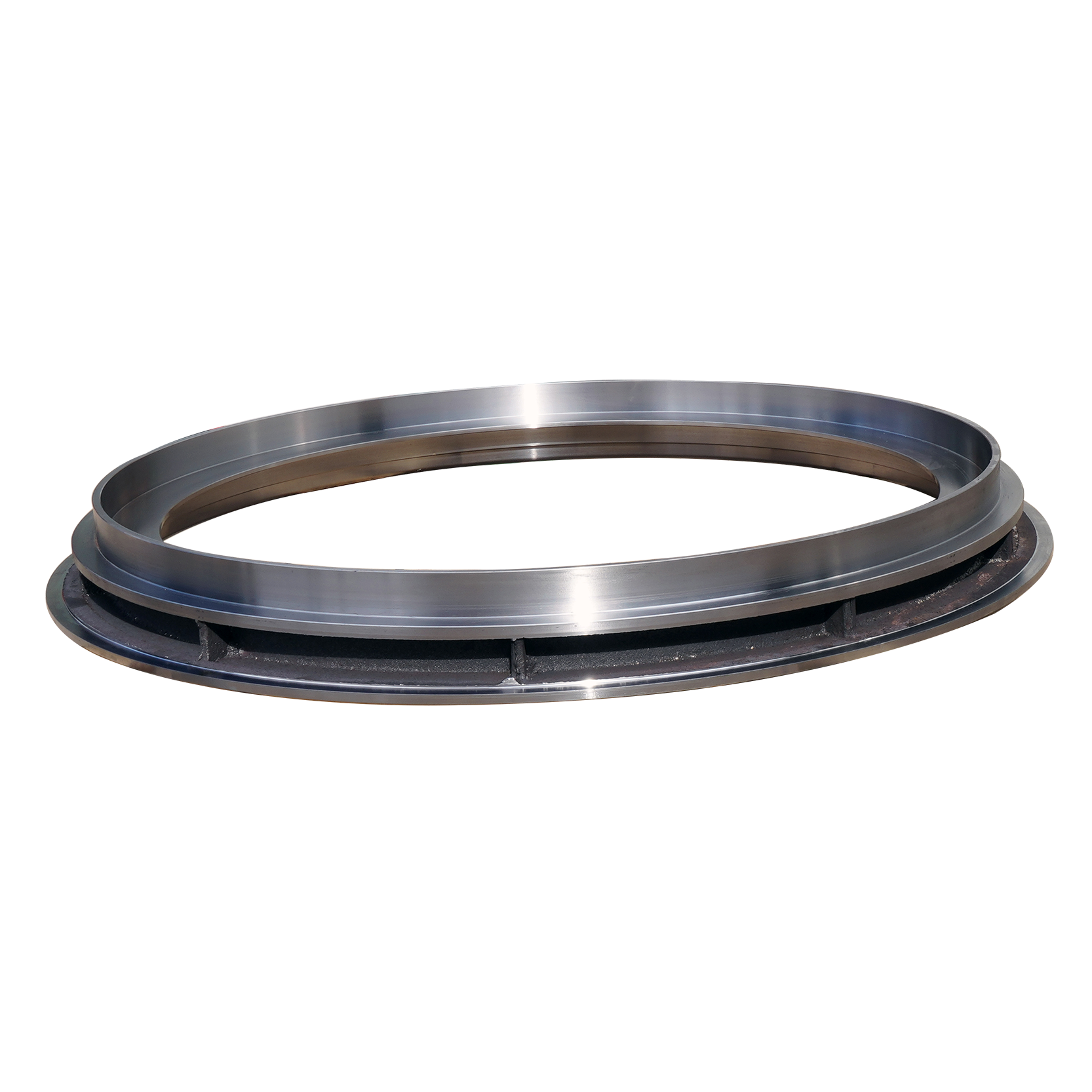

ductile iron pipe mould pallet manufacturer

Ductile iron pipes play a crucial role in modern infrastructure, particularly in water and wastewater management systems. As the demand for durable and reliable piping solutions increases, the need for high-quality manufacturing processes and equipment becomes ever more critical. One essential aspect of this manufacturing process is the use of efficient mould pallets, which are vital for shaping and forming ductile iron pipes to exact specifications.

Ductile iron pipe mould pallets are specifically designed for the rigorous demands of pipe manufacturing. They must withstand not only the weight and pressure of molten iron but also the high temperatures involved in the casting process. This necessitates the use of robust materials that guarantee longevity and reliability under extreme conditions. A reputable manufacturer will invest in advanced technology and equipment to produce mould pallets that ensure precise dimensions and surface finishes, which are crucial for the overall quality of the pipes.

The manufacturing process begins with the careful design of the mould pallets. This involves collaboration between engineers and manufacturers to specify the required dimensions, shapes, and other technical details. Utilizing computer-aided design (CAD) technologies, manufacturers can create mould pallets that perfectly fit within the production line, optimizing the workflow and ensuring consistency in product quality.

ductile iron pipe mould pallet manufacturer

Once the designs are finalized, the next step involves selecting the right materials for construction. High-quality steel and specialized alloys are typically used to enhance durability and resistance to wear. The manufacturing process may also incorporate heat treatment techniques to further increase the strength of the mould pallets.

After the mould pallets are produced, rigorous testing is conducted to ensure they meet industry standards and can endure the demanding environment of ductile iron pipe production

. Quality control is paramount; any imperfections can lead to significant defects in the final pipes, which can jeopardize infrastructure projects.In conclusion, the role of a ductile iron pipe mould pallet manufacturer is pivotal in ensuring the production of high-quality piping solutions. By focusing on advanced design, superior materials, and stringent quality control, manufacturers contribute significantly to the infrastructure sector, delivering products that meet the growing demands for durability and performance in water and wastewater systems. The future of ductile iron pipes is bright, driven by innovation and a commitment to quality in every stage of production.

-

Custom Furniture Hardware Durable & Affordable Solutions Shop Now

NewsJun.01,2025

-

SRC Concrete Pipe Bottom Ring Durable & Customizable Solutions

NewsJun.01,2025

-

Machine Base Casting Solutions Custom & ODM Precision Castings

NewsMay.31,2025

-

Custom Cast Steel Pipe Mould Pallets Heavy-Duty & Custom Solutions

NewsMay.31,2025

-

Cast Silicon Aluminum Alloy Heat Exchanger Suppliers & Exporters

NewsMay.31,2025

-

Precision Die Casting Services Custom & Machining Parts Supplier

NewsMay.31,2025