តុលា . 18, 2024 19:47 Back to list

Exporters of FRP Concrete Pipe Mold and Bottom Ring Solutions

The Importance of FRC Concrete Pipe Mold Bottom Rings in Modern Construction

In the realm of modern construction, efficient infrastructure development is paramount. Among the myriad of construction materials and techniques emerging in recent years, Fiber Reinforced Concrete (FRC) has gained significant traction, particularly for its ability to enhance the structural integrity and durability of concrete products. One essential component in the production of FRC concrete pipes is the mold, specifically the bottom ring. This article delves into the significance of FRC concrete pipe mold bottom rings and their role in the export industry.

Understanding FRC Concrete

Fiber Reinforced Concrete (FRC) is concrete that has had fibrous materials added to improve its structural performance. The addition of fibers, which can be made from various materials such as glass, carbon, or synthetic substances, enhances the tensile strength of concrete. This improvement is critical in applications such as pipe production, where the materials need to withstand significant stress and strain during transportation and installation.

FRC pipes are preferred for their resistance to cracking and improved load-bearing capacity, making them ideal for various applications, including drainage systems, sewers, and pressure pipes. To manufacture these pipes effectively, high-quality molds, including the bottom ring, are essential.

Significance of Concrete Pipe Mold Bottom Rings

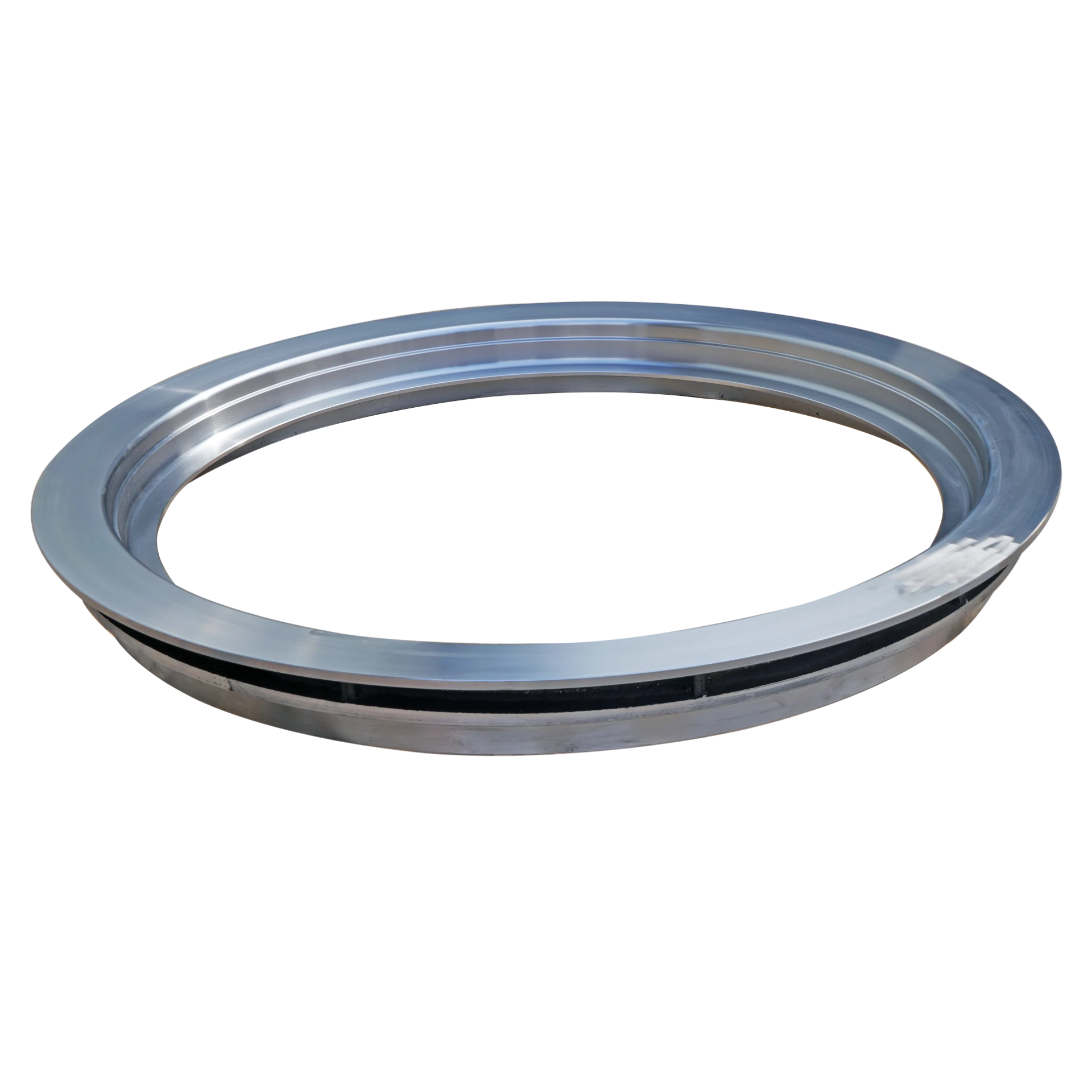

The bottom ring of a concrete pipe mold serves multiple functions in the manufacturing process. Firstly, it establishes the foundational shape and size of the pipe. Accurate dimensions are critical to ensuring that the pipes fit seamlessly in their designated applications. Secondly, the bottom ring provides structural support during the curing process, allowing the newly formed concrete to maintain its shape until it reaches the required strength.

Moreover, the design and material composition of the bottom ring can significantly influence the overall quality of the FRC pipe. Molds that are made from high-quality materials, typically steel or specialized composites, yield a better surface finish and dimensional accuracy. This precision is crucial, as any discrepancies can lead to weaknesses in the pipe itself, potentially resulting in failure when under load.

frc concrete pipe mold bottom ring exporters

The Export Market for FRC Concrete Pipe Mold Bottom Rings

The demand for FRC concrete pipe molds, particularly bottom rings, has seen a significant rise globally. Many countries, especially those experiencing rapid urbanization and infrastructure development, are seeking reliable suppliers of these components. Exporters around the world have a unique opportunity to cater to this growing market by providing high-quality molds that meet international standards.

Countries with established manufacturing capabilities, such as China, the United States, and Germany, are leading exporters of concrete pipe mold bottom rings. Manufacturers in these countries focus on innovation, developing molds that not only improve the efficiency of the production process but also extend the lifespan of the molds themselves.

In an increasingly competitive global market, exporters must prioritize quality, compliance with international regulations, and customer service to succeed. Building partnerships with local manufacturers in target markets can also enhance competitiveness, allowing exporters to understand specific regional needs better.

Conclusion

In conclusion, the importance of FRC concrete pipe mold bottom rings cannot be overstated in the context of modern construction and infrastructure development. As the demand for durable and efficient concrete products rises, so too does the need for high-quality molds. Suppliers and exporters of these components play a crucial role in supporting the construction industry by providing the necessary tools to produce superior FRC pipes.

As the global construction landscape continues to evolve, embracing innovation and maintaining high standards will be essential for those involved in the manufacturing and export of FRC concrete pipe molds. By focusing on quality and adaptability, exporters can ensure they remain at the forefront of this thriving market, contributing to the development of resilient infrastructure worldwide.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025