កុម្ភៈ . 14, 2025 12:25 Back to list

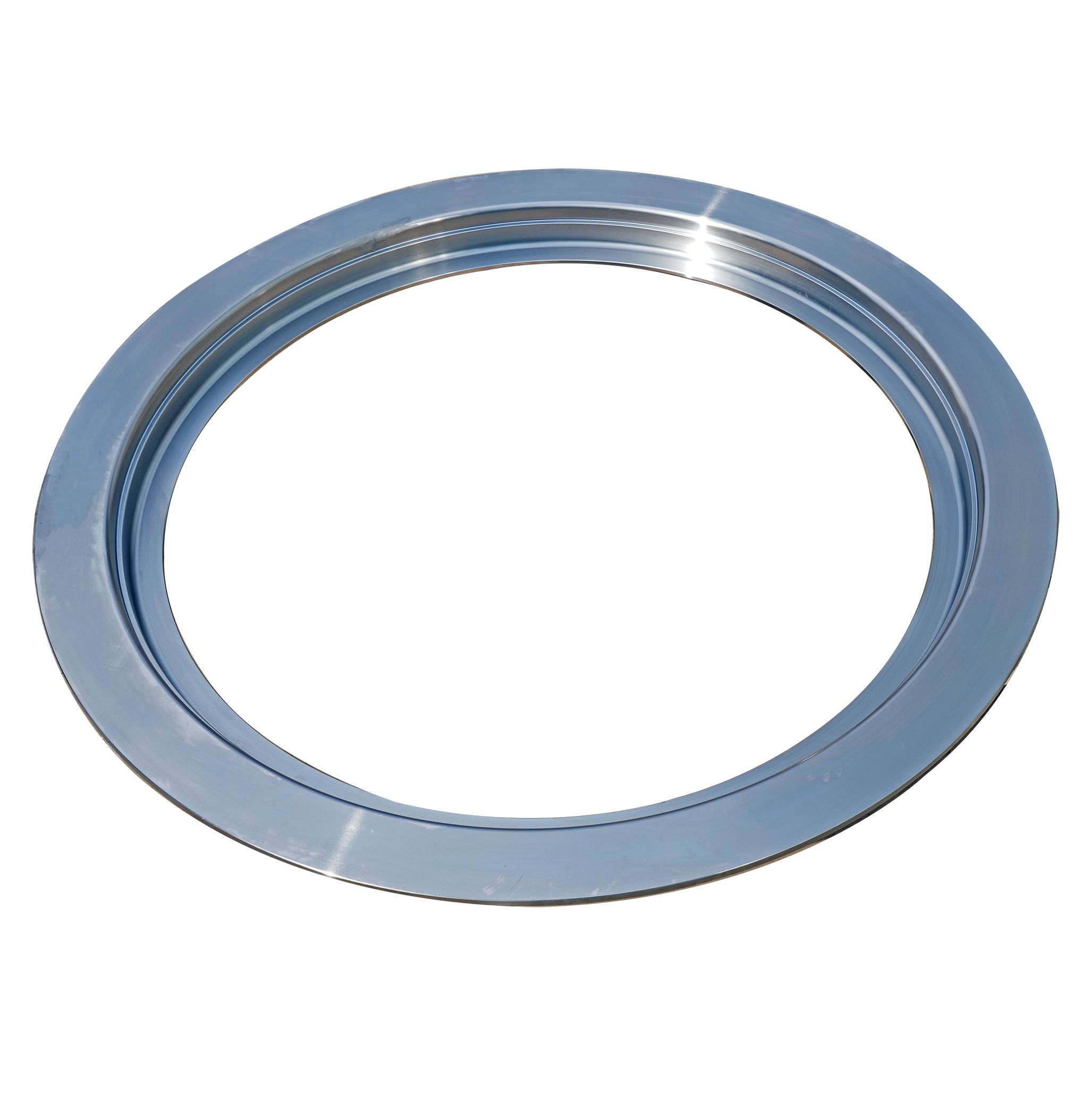

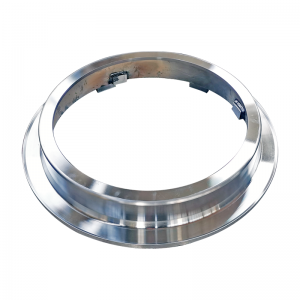

mixed flow heat exchanger

Mixed flow heat exchangers, an essential component in various industrial applications, offer a blend of efficiency and versatility. These exchangers are adept at handling both laminar and turbulent flow conditions, making them uniquely capable of optimizing heat transfer in diverse settings. By integrating the principles of thermodynamics and fluid mechanics, mixed flow heat exchangers provide an innovative solution to heat transfer challenges, enhancing industrial processes across multiple sectors.

Mixed flow heat exchangers also play a pivotal role in advancing energy sustainability. By optimizing heat transfer processes, these exchangers can significantly reduce energy consumption and waste heat emissions, contributing to a more sustainable operation. Industries committed to minimizing their carbon footprint can leverage these exchangers to enhance thermal efficiency and promote eco-friendly practices without compromising productivity or quality. Despite their benefits, the deployment of mixed flow heat exchangers must be accompanied by stringent regulatory and safety considerations. Compliance with industry standards, such as those set by ASME or ISO, ensures that heat exchangers operate safely and effectively under prescribed conditions. Conducting regular maintenance and performance assessments is crucial in sustaining operational integrity and preventing system failures, underscoring the importance of a proactive maintenance strategy. Trust in mixed flow heat exchanger technology is bolstered by extensive research and field-based performance evaluations. Peer-reviewed studies and case analyses provide empirical evidence supporting the efficacy of these exchangers, further reinforcing their authoritative standing in the industry. Additionally, partnerships between manufacturers and users can foster knowledge exchange, leading to enhanced product development and practical insights that drive continuous innovation. In conclusion, mixed flow heat exchangers represent a significant advancement in heat exchange technology, offering customized solutions that cater to complex industrial needs. Their ability to efficiently manage varying flow conditions, coupled with a strong foundation in engineering expertise and authoritative research, positions them as a trusted choice for industries worldwide. By prioritizing energy efficiency, adherence to regulatory standards, and continual innovation, mixed flow heat exchangers stand out as a pivotal component in optimizing industrial thermal processes.

Mixed flow heat exchangers also play a pivotal role in advancing energy sustainability. By optimizing heat transfer processes, these exchangers can significantly reduce energy consumption and waste heat emissions, contributing to a more sustainable operation. Industries committed to minimizing their carbon footprint can leverage these exchangers to enhance thermal efficiency and promote eco-friendly practices without compromising productivity or quality. Despite their benefits, the deployment of mixed flow heat exchangers must be accompanied by stringent regulatory and safety considerations. Compliance with industry standards, such as those set by ASME or ISO, ensures that heat exchangers operate safely and effectively under prescribed conditions. Conducting regular maintenance and performance assessments is crucial in sustaining operational integrity and preventing system failures, underscoring the importance of a proactive maintenance strategy. Trust in mixed flow heat exchanger technology is bolstered by extensive research and field-based performance evaluations. Peer-reviewed studies and case analyses provide empirical evidence supporting the efficacy of these exchangers, further reinforcing their authoritative standing in the industry. Additionally, partnerships between manufacturers and users can foster knowledge exchange, leading to enhanced product development and practical insights that drive continuous innovation. In conclusion, mixed flow heat exchangers represent a significant advancement in heat exchange technology, offering customized solutions that cater to complex industrial needs. Their ability to efficiently manage varying flow conditions, coupled with a strong foundation in engineering expertise and authoritative research, positions them as a trusted choice for industries worldwide. By prioritizing energy efficiency, adherence to regulatory standards, and continual innovation, mixed flow heat exchangers stand out as a pivotal component in optimizing industrial thermal processes.

Share

Pervious:

Next:

Latest news

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025