មករា . 20, 2025 08:40 Back to list

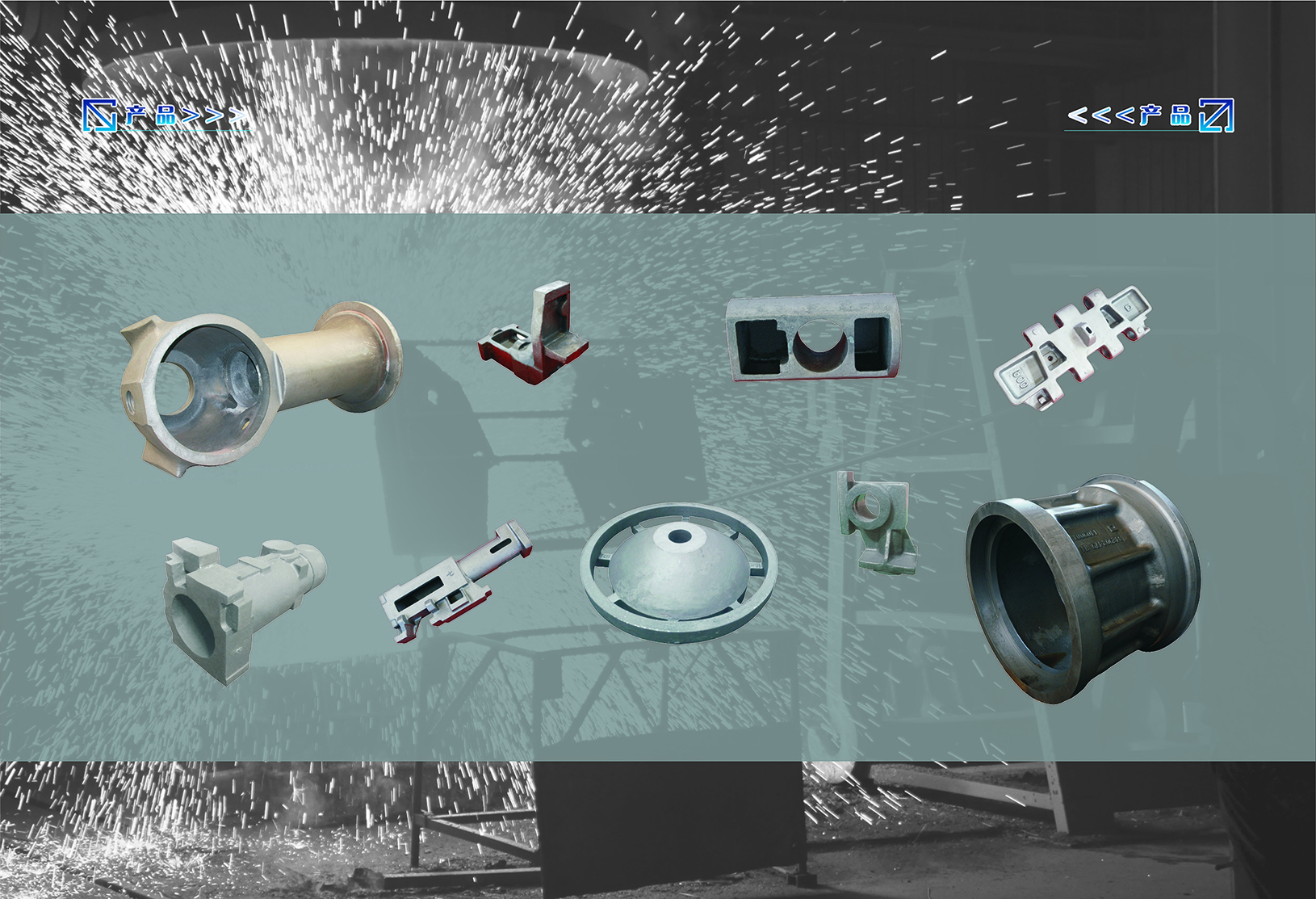

parts stainless steel

Stainless steel parts are indispensable in today's world. Known for their remarkable resistance to corrosion, stainless steel components are integral to a variety of industries, including automotive, aerospace, medical, and construction. This material’s resilience and versatility trace back to its unique composition and properties, such as high tensile strength, resistance to extreme temperatures, and an aesthetically pleasing finish that suits diverse applications.

Construction industries value stainless steel for its contribution to sustainability and long-term performance. Structures such as bridges, buildings, and monuments benefit from its ability to withstand harsh weather conditions without degrading. Moreover, stainless steel's recyclability underscores environmental responsibility practices, aligning well with modern sustainability goals. The automotive sector has seen a surge in stainless steel parts, driven by the trend towards electric vehicles (EVs). Components such as exhaust systems, chassis, and mufflers exploit stainless steel’s lightweight and strength properties, enhancing vehicle efficiency and safety. The ongoing shift towards sustainable and renewable energy further boosts stainless steel's appeal in crafting resilient, future-ready automotive parts. Globally, the development of new alloys and the refinement of existing ones demonstrate a commitment to continuous improvement and adaptation. Industry leaders and researchers constantly push the boundaries, exploring ways to enhance the inherent properties of stainless steel, addressing emerging challenges, and ensuring its competitiveness in an ever-evolving marketplace. Choosing stainless steel parts mandates a thorough understanding of the specific application requirements and environmental conditions. Consulting with experts can provide invaluable insights to ensure the right grade is selected, optimizing both cost and performance. Trustworthy suppliers, with a proven track record, can offer guidance through the purchasing process, ensuring high-quality materials and proper certifications. In conclusion, stainless steel parts embody a meld of experience, expertise, authoritativeness, and trustworthiness, making them the optimal choice across numerous industries. Their application not only addresses immediate challenges but also adheres to the demands of future innovation. Whether ensuring the safety and efficacy of medical instruments or supporting the structural integrity of monumental architecture, stainless steel stands as a beacon of reliability and excellence in material science. As industries continue to evolve and pursue new frontiers, stainless steel will undoubtedly remain a cornerstone in the quest for superior, sustainable solutions.

Construction industries value stainless steel for its contribution to sustainability and long-term performance. Structures such as bridges, buildings, and monuments benefit from its ability to withstand harsh weather conditions without degrading. Moreover, stainless steel's recyclability underscores environmental responsibility practices, aligning well with modern sustainability goals. The automotive sector has seen a surge in stainless steel parts, driven by the trend towards electric vehicles (EVs). Components such as exhaust systems, chassis, and mufflers exploit stainless steel’s lightweight and strength properties, enhancing vehicle efficiency and safety. The ongoing shift towards sustainable and renewable energy further boosts stainless steel's appeal in crafting resilient, future-ready automotive parts. Globally, the development of new alloys and the refinement of existing ones demonstrate a commitment to continuous improvement and adaptation. Industry leaders and researchers constantly push the boundaries, exploring ways to enhance the inherent properties of stainless steel, addressing emerging challenges, and ensuring its competitiveness in an ever-evolving marketplace. Choosing stainless steel parts mandates a thorough understanding of the specific application requirements and environmental conditions. Consulting with experts can provide invaluable insights to ensure the right grade is selected, optimizing both cost and performance. Trustworthy suppliers, with a proven track record, can offer guidance through the purchasing process, ensuring high-quality materials and proper certifications. In conclusion, stainless steel parts embody a meld of experience, expertise, authoritativeness, and trustworthiness, making them the optimal choice across numerous industries. Their application not only addresses immediate challenges but also adheres to the demands of future innovation. Whether ensuring the safety and efficacy of medical instruments or supporting the structural integrity of monumental architecture, stainless steel stands as a beacon of reliability and excellence in material science. As industries continue to evolve and pursue new frontiers, stainless steel will undoubtedly remain a cornerstone in the quest for superior, sustainable solutions.

Share

Pervious:

Next:

Latest news

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025