- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ಜನ . 16, 2025 04:41 Back to list

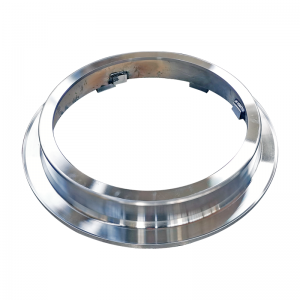

Marine Gear Box Made of Special Alloy Steel

Grey iron casting, also known as gray iron casting, is an indispensable process in the manufacturing sector due to its versatility and extensive range of applications. This method encompasses the casting of iron with a higher carbon content, represented visibly by its grayish fractured surface due to the presence of graphite flakes. Understanding the intricacies of grey iron casting can provide significant insights into its role in modern production and its continuous evolution.

Trustworthiness in grey iron casting is reinforced by the continuous improvement in the quality control processes across the casting industry. Advanced technologies such as 3D modeling and computational fluid dynamics simulations allow for precise mold design and prediction of the casting process's outcomes, reducing defects and ensuring consistent quality. Non-destructive testing methods, including ultrasonic and magnetic particle inspections, provide further assurance that the structural integrity of grey iron castings meets the highest industry standards. For product designers and manufacturers, understanding these dimensions of grey iron casting can elevate their design and production processes. By leveraging its damping properties and heat conductivity, one can design components that benefit from reduced mechanical stress and improved longevity. Moreover, the cost efficiency due to reduced machining times and lower raw material costs make it a favorable option for large-scale production without compromising on quality. In conclusion, grey iron casting is not merely a relic of the industrial past but a continually evolving field that adapts to modern engineering challenges. Its blend of machinability, reliability, and adaptability places it at the forefront of materials chosen for a broad spectrum of applications. As industries push towards more sustainable and efficient manufacturing practices, grey iron casting stands out as a trustworthy, authoritative, and expertly handled process that meets the demands of both traditional and emerging markets.

Trustworthiness in grey iron casting is reinforced by the continuous improvement in the quality control processes across the casting industry. Advanced technologies such as 3D modeling and computational fluid dynamics simulations allow for precise mold design and prediction of the casting process's outcomes, reducing defects and ensuring consistent quality. Non-destructive testing methods, including ultrasonic and magnetic particle inspections, provide further assurance that the structural integrity of grey iron castings meets the highest industry standards. For product designers and manufacturers, understanding these dimensions of grey iron casting can elevate their design and production processes. By leveraging its damping properties and heat conductivity, one can design components that benefit from reduced mechanical stress and improved longevity. Moreover, the cost efficiency due to reduced machining times and lower raw material costs make it a favorable option for large-scale production without compromising on quality. In conclusion, grey iron casting is not merely a relic of the industrial past but a continually evolving field that adapts to modern engineering challenges. Its blend of machinability, reliability, and adaptability places it at the forefront of materials chosen for a broad spectrum of applications. As industries push towards more sustainable and efficient manufacturing practices, grey iron casting stands out as a trustworthy, authoritative, and expertly handled process that meets the demands of both traditional and emerging markets.

Share

Latest news

-

Buy Cast Silicon Aluminum Hot Water Heat Exchangers Efficient & Durable

NewsMay.15,2025

-

Precision Stainless Steel Casting Services Sand/Investment/Die Casting

NewsMay.15,2025

-

China Investment Casting Parts High Precision & Durable Solutions

NewsMay.14,2025

-

Water Glass Sand Casting Custom & ODM Solutions, High Precision

NewsMay.14,2025

-

Ductile Iron Casting Solutions High-Strength & Corrosion-Resistant

NewsMay.13,2025

-

Custom Low Nitrogen Condensing Gas Boilers for Domestic Hot Water

NewsMay.13,2025