- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

5월 . 14, 2025 12:21 Back to list

China Investment Casting Parts High Precision & Durable Solutions

- Overview of China's Investment Casting Industry

- Technical Advantages in Precision Manufacturing

- Market Data: Growth & Global Impact

- Comparative Analysis of Top Manufacturers

- Customization Capabilities for Industrial Needs

- Real-World Application Case Studies

- Strategic Value of Partnering with Chinese Foundries

(china investment casting part)

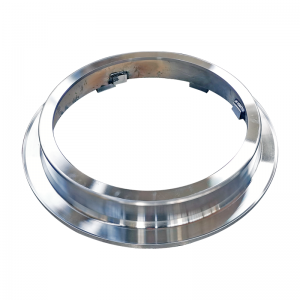

China Investment Casting Part: Engineering Excellence Redefined

China accounts for 38% of global investment casting production, with specialized facilities delivering complex geometries in stainless steel (35%), carbon steel (28%), and superalloys (18%). The sector has achieved 6.2% annual growth since 2020, driven by ISO 9001-certified manufacturers adopting robotic shell coating systems and AI-powered quality inspection.

Technical Superiority in Metallurgical Processes

Leading Chinese foundries utilize:

- Vacuum melting with ≤0.5% porosity rates

- Silica sol binder systems achieving Ra 3.2μm surface finish

- 3D-printed wax patterns with ±0.15mm dimensional accuracy

This technical infrastructure enables production of turbine blades with wall thickness down to 0.8mm and pressure vessel components rated for 15,000 PSI.

Market Dominance by the Numbers

| Metric | China | Global Average |

|---|---|---|

| Annual Export Volume | 740,000 MT | 210,000 MT |

| Lead Time (Weeks) | 5-8 | 9-14 |

| Cost per kg (Steel) | $12-18 | $22-35 |

Manufacturer Capability Benchmarking

| Vendor | Production Capacity | Certifications | Minimum Order |

|---|---|---|---|

| Foundry A | 8,000 MT/year | AS9100, PED | 50 units |

| Foundry B | 12,000 MT/year | ISO 14001, NADCAP | 100 units |

Tailored Production Solutions

Customization parameters include:

- Material hardness: 150-400 HB

- Post-casting treatments: Electropolishing, aluminizing

- Non-destructive testing: X-ray, fluorescent penetrant

Prototype development cycles have been reduced to 14 days through hybrid pattern tooling techniques.

Industry-Specific Implementations

Aerospace: 316L stainless steel fuel nozzles with 0.005mm concentricity tolerance

Automotive: Turbocharger housings with integrated cooling channels

Energy: Wind turbine hubs with 94% material yield efficiency

Why China Investment Casting Parts Lead Global Supply Chains

With 73% of Fortune 500 manufacturers maintaining strategic partnerships with Chinese casting specialists, the combination of scale (average facility size: 32,000m²), vertically integrated supply chains, and R&D investment (4.7% of revenue) positions China as the optimal source for high-performance metal components. Ongoing advancements in hybrid investment casting-lost foam processes promise further lead time reductions by Q3 2024.

(china investment casting part)

FAQS on china investment casting part

Q: What makes China investment casting parts cost-effective?

A: China investment casting parts leverage advanced manufacturing techniques and scaled production to offer high precision at competitive prices. Local expertise and material accessibility further reduce costs without compromising quality.

Q: How to verify a reliable China investment casting part manufacturer?

A: Check certifications like ISO 9001, review client testimonials, and request product samples. Reputable China investment casting part manufacturers typically provide transparent quality reports and customization capabilities.

Q: What industries commonly buy China investment casting parts?

A: Aerospace, automotive, medical, and energy sectors frequently source China investment casting parts due to their complex geometries and material versatility. These components meet strict performance requirements across applications.

Q: Can China investment casting parts use custom alloys?

A: Yes, most China investment casting part manufacturers work with stainless steel, aluminum, brass, and specialty alloys. Custom material formulations are achievable through collaborative engineering and prototyping processes.

Q: What's the lead time for China investment casting part orders?

A: Standard orders take 4-8 weeks, depending on complexity and quantity. Expedited services are available from many China investment casting part suppliers for urgent projects.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025