- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

7월 . 24, 2025 01:01 Back to list

OEM Cast Silicon Aluminum Alloy Heat Exchanger for Efficient Cooling Solutions

About Shijiazhuang Casiting Trading Co., Ltd.

Shijiazhuang Casiting Trading Co., Ltd. is a leader in OEM casting solutions, specializing in high-quality, customized metal sand casting, stainless steel castings, and heat exchanger components. With years of expertise in manufacturing and exporting, the company delivers reliable oem cast silicon aluminum alloy heat exchanger solutions to global partners.

- Official Website: https://www.casiting.com

- Corporate Phone: 0086-311-67596450

- Email: hjr1024@aliyun.com

- Mobile: 008613832327186

- Headquarter: RM315, Baihui Building, No.57 Sizhong Road, Qiaoxi District, Shijiazhuang City, Hebei, China

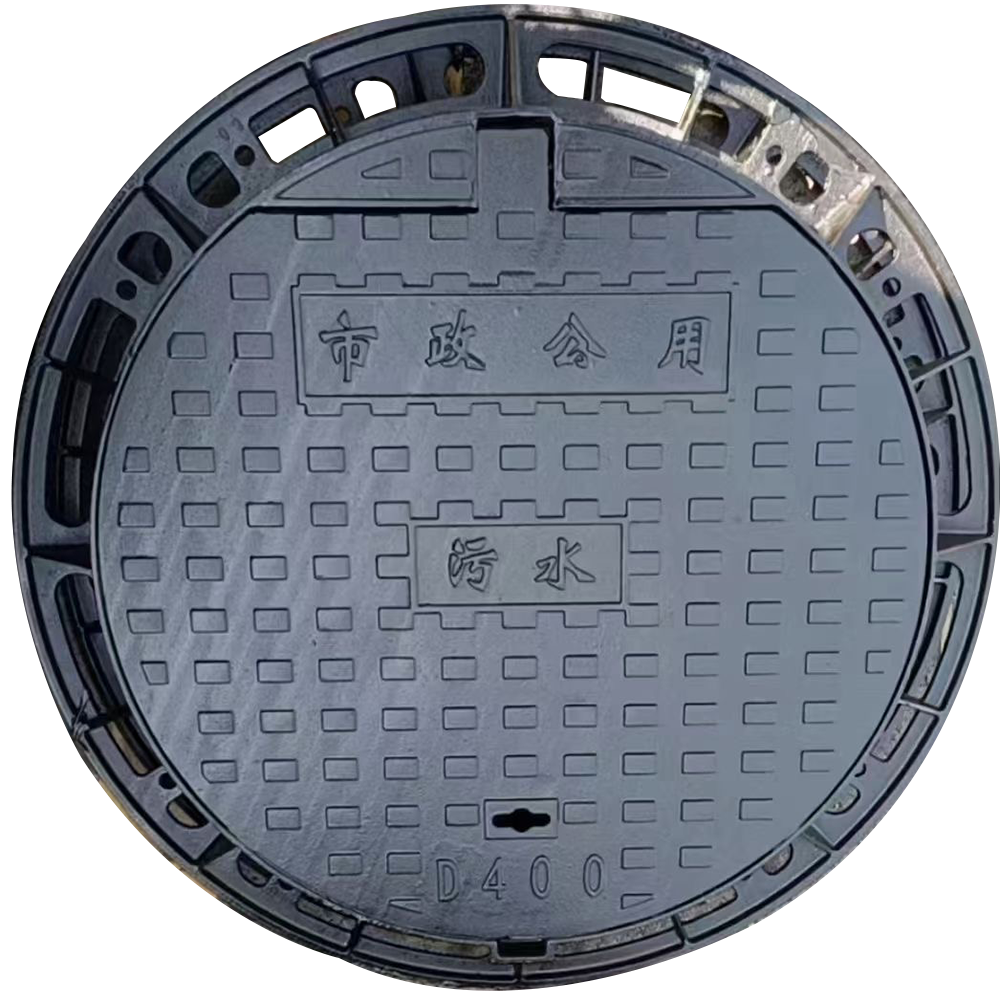

Featured Product: Ductile Cast Iron Manhole Cover Series

Product Name: Ductile Cast Iron Manhole Cover / Ductile Graphite Manhole Cover / Ductile Anti-theft Manhole Cover

Short Description:

- Material: QT/HT

- Usage: Accessories for crushing machine

- Casting Technology: Wet Sand Casting

- Unit Weight: 84–290kg

- Production Equipment: Auto Molding Production Line

- Productivity: 20,000 tons/year

- OEM/ODM: Yes

Industry Overview: OEM Cast Silicon Aluminum Alloy Heat Exchanger Market

OEM cast silicon aluminum alloy heat exchanger products are central to modern air conditioning, automotive, HVAC, and industrial applications, owing to their excellent strength, corrosion resistance, and thermal conductivity. With the advancement in OEM casting parts and OEM metal sand casting technology, suppliers like Shijiazhuang Casiting Trading Co., Ltd. offer optimized solutions for global demand.

According to the ScienceDirect Engineering Topics, the adoption of silicon aluminum alloys in OEM heat exchangers has increased, driven by lightweighting trends, stricter emissions rules, and the need for higher heat transfer efficiencies.

Focus on Industry Trends

- Growing Demand: Rising applications in automotive, renewable energy, and power plants are fueling the oem cast silicon aluminum alloy heat exchanger market.

- Material Innovation: The incorporation of advanced silicon aluminum alloys provides superior corrosion resistance and longevity versus traditional alloys.

- Advanced Manufacturing: Automation, precision sand casting, and OEM stainless steel casting foundry techniques have elevated product reliability and cost-efficiency.

- Regulatory Compliance: Compliance with ISO, ASTM, and EN standards is becoming critical for global market access.

- Sustainability: Recyclable alloys and energy-reduced processes are prioritized in OEM supplier selection.

Technical Parameters Table: OEM Cast Silicon Aluminum Alloy Heat Exchanger

| Parameter | Typical Value | Industry Benchmark | Remarks |

|---|---|---|---|

| Alloy Grade | AlSi10Mg (EN AC-43000), AlSi7Mg, AlSi12 | AlSi10Mg most used | High Si increases castability and corrosion resistance |

| Thermal Conductivity (W/m·K) | 140 – 180 | 160 | Critical for heat exchanger efficiency |

| Tensile Strength (MPa) | 200 – 250 | 230 | Needs to withstand operation pressures |

| Yield Strength (MPa) | 120 – 160 | 140 | Mechanical durability indicator |

| Elongation at Break (%) | 2.5 – 9 | 5 | Higher elongation means better ductility |

| Corrosion Resistance | Excellent (Salt Spray > 1000h) | High | Required for HVAC, marine apps |

| Ductility | Medium-High | Medium | Depends on Mg/Si content |

| Production Process | OEM Metal Sand Casting, Die Casting | Auto-line, Molding | Precision impacts final quality |

| Operating Temperature (°C) | -40 ~ 250 | 200 | Industry average |

| Life Cycle (years) | 10 – 30 | 20 | Based on application/maintenance |

Technical Parameter Trends: OEM Cast Silicon Aluminum Alloy Heat Exchanger

Data source: Industry averages and ResearchGate: Study on Silicon-Aluminum Alloys for Heat Exchangers

Applications of OEM Cast Silicon Aluminum Alloy Heat Exchangers

- Automotive Sector: Radiators, engine coolers, EGR modules, battery cooling for EVs.

- HVAC Industry: Chillers, condensers, evaporators, heat recovery ventilation (HRV).

- Renewable Energy: Solar thermal energy conversion, wind power gearboxes.

- Industrial Machinery: Compressors, plant process cooling, reactors.

- Marine & Chemical Process: Anti-corrosion exchangers for ships, off-shore platforms.

- Electronics & Telecom: Data center cooling, power electronics thermal management.

OEM Casting Parts, Metal Sand Casting & Stainless Steel Foundry Capabilities

Shijiazhuang Casiting Trading Co., Ltd. offers a full suite of oem casting parts, oem metal sand casting, and runs a modern oem stainless steel casting foundry:

- Custom OEM/ODM projects based on drawings & samples.

- Flexible small-to-mass batch production.

- Strict process controls: Spectrometers, CMM, X-ray, UT & PT validation.

- Materials: Silicon aluminum alloys, SG/Ductile iron, stainless steel, nickel alloys, bronze.

- Certifications: ISO9001, SGS, BV, CE.

- Application industries: Municipal, mining, machinery, energy, construction, agriculture, transportation.

Technical Comparison & Visualization: Manhole Cover Series

Main Technical Indicators (Ductile Cast Iron/Graphite/Anti-theft Covers)

| Parameter | Ductile Iron | Graphite Iron | Anti-theft Cover |

|---|---|---|---|

| Material | Spheroidal Graphite Cast Iron (QT500-7 / HT250) | High Carbon Graphitic | Composite reinforced ductile iron |

| Tensile Strength (MPa) | ≥500 | ≥450 | ≥520 |

| Yield Strength (MPa) | ≥320 | ≥300 | ≥350 |

| Impact Value (J/cm²) | ≥13 | ≥12 | ≥18 |

| Unit Weight (kg) | 84~290 | 88~250 | 90~290 |

| Corrosion Resistance | Excellent | Good | Excellent |

| Application | Crushing Machines, Roads | General Machinery | Urban anti-theft, drainage |

Professional FAQ About OEM Cast Silicon Aluminum Alloy Heat Exchangers & Manhole Covers

- 1. What are the primary materials used in OEM cast silicon aluminum alloy heat exchanger manufacturing?

- Most commonly, silicon aluminum alloys such as AlSi10Mg, AlSi7Mg, and AlSi12 are used. These alloys are selected for their excellent casting performance, corrosion resistance, and thermal conductivity. Source: ScienceDirect

- 2. How does OEM metal sand casting improve product quality?

- OEM metal sand casting allows for precise material control, high-variety customization, and consistent mechanical properties. With advances in automated molding lines (as used by Casiting), dimensional accuracy and surface finish have significantly increased.

- 3. What are the advantages of ductile cast iron manhole covers over conventional types?

- Ductile cast iron offers high tensile/yield strength, excellent impact resistance, and superior corrosion life compared to gray cast iron, making it ideal for heavy-load infrastructure. See ASTM A536 Standard.

- 4. What are typical technical parameters of a high-performance heat exchanger?

- Key parameters include: Thermal conductivity (140–180 W/m·K), tensile strength (200–250 MPa), yield strength (120–160 MPa), elongation (2.5–9%), and salt spray corrosion resistance >1000h.

- 5. Which installation standards must heat exchanger castings comply with?

- ISO 9001, EN 13445 (unfired pressure vessels), ASTM B179, and API 661 are commonly referenced for heat exchanger installations.

- 6. What OEM/ODM capabilities does Shijiazhuang Casiting supply?

- Casiting offers customer-specific drawings, rapid prototyping, custom alloy development, full traceability, and batch testing for extreme service needs.

- 7. How does anti-theft manhole cover design enhance urban safety?

- By integrating rigid locking mechanisms and composite reinforcement within ductile iron, anti-theft covers prevent unauthorized access and deter vandalism in city infrastructure.

Optimizing for SEO with Key Phrases

To achieve maximum visibility, oem cast silicon aluminum alloy heat exchanger and related keywords like oem casting parts, oem metal sand casting, and oem stainless steel casting foundry are integrated naturally within this page.

Learn more about this product from our oem cast silicon aluminum alloy heat exchanger specialists.

Contact Shijiazhuang Casiting Trading Co., Ltd.

- Phone: 0086-311-67596450

- Email: hjr1024@aliyun.com

- Mobile: 008613832327186

- Address: RM315, Baihui Building, No.57 Sizhong Road, Qiaoxi District, Shijiazhuang City, Hebei, China

- Website: www.casiting.com

Conclusion & Further Reading

The oem cast silicon aluminum alloy heat exchanger market is rapidly evolving towards higher performance, stricter quality standards, and sustainability. Manufacturers like Shijiazhuang Casiting Trading Co., Ltd. employ state-of-the-art casting technologies to meet diverse industrial demands, from automotive to municipal infrastructure with products like ductile cast iron manhole covers.

For further professional insights and networking, refer to:

- International Journal of Heat and Mass Transfer: Elsevier IJHMT

- China Foundry Association Technical Forum: foundrynations.com

- Cast Iron Manhole Cover Standards: ASTM A536

- ResearchGate: Study on Silicon-Aluminum Alloys for Heat Exchangers

- ScienceDirect Aluminum Heat Exchanger Topic: sciencedirect.com

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025