- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

11월 . 15, 2024 23:43 Back to list

sand cast factory

The Art and Science of Sand Casting A Journey Through a Sand Cast Factory

Sand casting has stood the test of time as one of the most versatile and widely used methods for producing metal parts. Within the bustling environment of a sand cast factory, the intricate interplay of art and science unfolds, revealing the meticulous processes that transform raw materials into functional components. This traditional foundry method, known for its efficiency and adaptability, plays a crucial role in various industries, including automotive, aerospace, and construction.

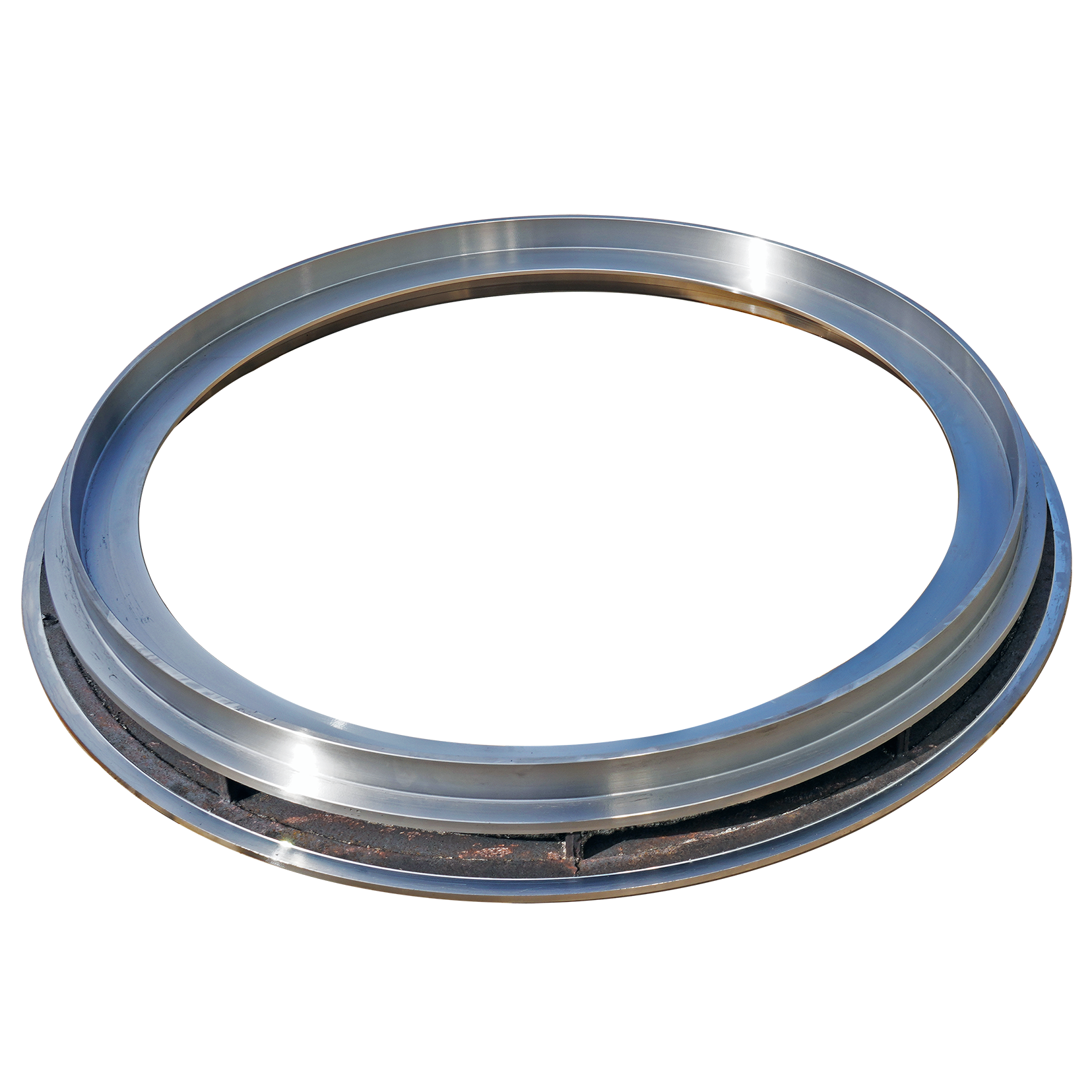

At the core of a sand cast factory is the creation of molds. Molding sand, a specially formulated mixture of silica sand, clay, and water, is prepared to hold its shape while ensuring proper flowability. The first step is to create a pattern, typically made from metal or plastic, which serves as a template for the desired part. This pattern is pressed into the prepared sand to form a mold cavity. The art lies in the precision of this process, as any imperfections in the pattern can lead to flaws in the final product.

Once the mold is created, it is joined together, forming a complete cavity ready for pouring. Workers at the sand cast factory meticulously inspect each mold for defects, ensuring every detail matches specifications. The monitoring of temperature and quality of the molten metal is equally critical. Typically, metals such as aluminum, cast iron, or bronze are heated until they reach a liquid state before being poured into the mold. This step requires expertise and experience, as improper pouring can result in defects like air pockets and incomplete filling.

sand cast factory

Cooling and solidification take place after the metal is poured into the mold. The sand cast factory environment is filled with anticipation as workers monitor the cooling process, which can vary depending on the metal used and the wall thickness of the casting. Once cooled, the molds are broken apart, revealing the newly formed metal part. This is where the magic happens, but the process is not yet complete.

Post-processing is essential for ensuring that the final product meets quality standards. The castings may undergo several finishing processes, including sandblasting, machining, and surface treatment. These steps enhance the appearance and durability of the metal part, transforming it from a rough cast to a polished finish suitable for its intended application.

In conclusion, a sand cast factory epitomizes the blend of tradition and innovation. The intricate methods employed in sand casting highlight the craftsmanship involved in producing high-quality metal parts. As industries continue to evolve, the sand cast factory remains a testament to enduring techniques that cater to modern demands, ensuring that this time-honored practice will continue to thrive in the future.

-

Custom Furniture Hardware Durable & Affordable Solutions Shop Now

NewsJun.01,2025

-

SRC Concrete Pipe Bottom Ring Durable & Customizable Solutions

NewsJun.01,2025

-

Machine Base Casting Solutions Custom & ODM Precision Castings

NewsMay.31,2025

-

Custom Cast Steel Pipe Mould Pallets Heavy-Duty & Custom Solutions

NewsMay.31,2025

-

Cast Silicon Aluminum Alloy Heat Exchanger Suppliers & Exporters

NewsMay.31,2025

-

Precision Die Casting Services Custom & Machining Parts Supplier

NewsMay.31,2025