- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

تشرینی یەکەم . 11, 2024 06:48 Back to list

Exporters of Casting Components and Parts in the Global Market

The Dynamics of Casting Parts Exporters A Comprehensive Overview

In the contemporary global marketplace, manufacturing industries continually seek efficient solutions to enhance production processes and reduce costs. One such solution is the reliance on casting parts, which are integral components in numerous applications, from automotive to aerospace. The role of casting parts exporters is vital in this ecosystem, as they facilitate the distribution of high-quality components across international markets.

Understanding Casting Parts

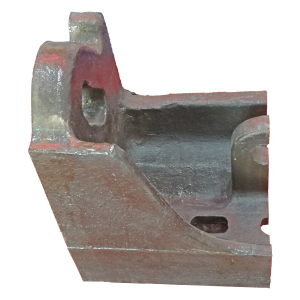

Casting is a manufacturing process where liquid material is poured into a mold and allowed to solidify. This technique can be employed with various materials, including metals, plastic, and ceramics, yielding complex shapes with precise dimensions. In industries where performance, durability, and reliability are paramount, the significance of casting parts cannot be overstated. They are widely used for engine blocks, transmission cases, housings, and many other crucial components.

The Global Landscape of Casting Parts Exporters

The global demand for casting parts has surged due to the rapid expansion of industries, particularly in emerging markets. Countries such as China, India, and Brazil have become frontline players, just as Germany, the United States, and Japan remain pivotal due to their established manufacturing bases. The competitive landscape of casting parts exporters is dynamic, characterized by a blend of traditional manufacturers and innovative newcomers.

Key Factors Influencing the Export of Casting Parts

1. Quality and Standards The quality of casting parts is of utmost importance for their efficacy and reliability in applications. Exporters must adhere to international quality standards such as ISO 9001, ISO/TS 16949, or specific client requirements. Ensuring high-quality production processes and materials is a key differentiator for successful exporters.

2. Technological Advancements Modern casting technology, including 3D printing and computer-aided designs (CAD), has transformed the manufacturing process. Exporters that leverage these technologies can produce complex designs with improved accuracy and reduced lead times. This evolution not only enhances product quality but also provides a competitive edge in pricing.

casting parts exporters

3. Cost Competitiveness Pricing remains a critical factor for casting parts exporters. Manufacturers in regions with lower labor costs can offer competitive pricing, attracting clients from higher-cost regions. However, the focus should not solely be on low prices; exporters must also balance cost with quality and service.

4. Sustainability Practices As the global economy shifts towards sustainability, many industries demand that their suppliers adhere to environmental standards. Casting parts exporters must adopt sustainable practices, such as reducing waste and utilizing recyclable materials, to meet the growing expectations of environmentally conscious clients.

5. Regional Trade Policies Exporters need to navigate various trade regulations, tariffs, and import/export laws that impact the flow of goods between countries. Familiarity with these regulations allows exporters to strategically plan their operations and avoid potential disruptions.

The Future of Casting Parts Exporters

Looking ahead, the future of casting parts exporters appears promising, albeit with challenges. The increasing automation of manufacturing processes represents both an opportunity and a challenge, necessitating investment in new technologies and skills. Moreover, the rise of electric vehicles (EVs) is expected to create new demands for lightweight and innovative casting materials, as manufacturers seek to enhance vehicle efficiency.

Furthermore, as industries continually move towards more personalized and specialized products, casting parts exporters will need to adapt by offering customized solutions. Collaborating closely with clients to understand their specifications and requirements will be key to fostering long-term partnerships.

Conclusion

Casting parts exporters play a crucial role in the global manufacturing landscape, bridging the gap between production and consumption. As industries evolve, adapting to changes in technology, sustainability measures, and market demands will be essential for these exporters to remain competitive. With a keen focus on quality, innovation, and customer collaboration, casting parts exporters can navigate the complexities of the global market and contribute significantly to the manufacturing supply chain.

-

Buy Cast Silicon Aluminum Hot Water Heat Exchangers Efficient & Durable

NewsMay.15,2025

-

Precision Stainless Steel Casting Services Sand/Investment/Die Casting

NewsMay.15,2025

-

China Investment Casting Parts High Precision & Durable Solutions

NewsMay.14,2025

-

Water Glass Sand Casting Custom & ODM Solutions, High Precision

NewsMay.14,2025

-

Ductile Iron Casting Solutions High-Strength & Corrosion-Resistant

NewsMay.13,2025

-

Custom Low Nitrogen Condensing Gas Boilers for Domestic Hot Water

NewsMay.13,2025