تشرینی دووەم . 24, 2024 11:16 Back to list

Manufacturers of Concrete Pipe Moulds and Pallets for High-Quality Construction Solutions

The Role of SRC Concrete Pipe Mould Pallet Factories in Modern Construction

In recent years, the construction industry has witnessed remarkable advancements, driven by the need for efficiency, sustainability, and innovation. One such innovation is the introduction and evolution of SRC (Steel Reinforced Concrete) concrete pipes and their associated moulds and pallets. These components play a significant role in the manufacturing process of concrete pipes, which are crucial for various applications, including drainage systems, sewage, and irrigation. This article explores the importance of SRC concrete pipe mould pallet factories and their contribution to modern construction.

Understanding SRC Concrete Pipes

SRC concrete pipes are known for their high durability and strength, attributes that make them ideal for heavy-load applications. The incorporation of steel reinforcement within the concrete enhances the material's structural integrity, offering resistance to cracking and compressive stresses. These pipes are particularly valuable in infrastructure projects, where reliability is paramount, such as in the construction of highways, bridges, and urban drainage systems.

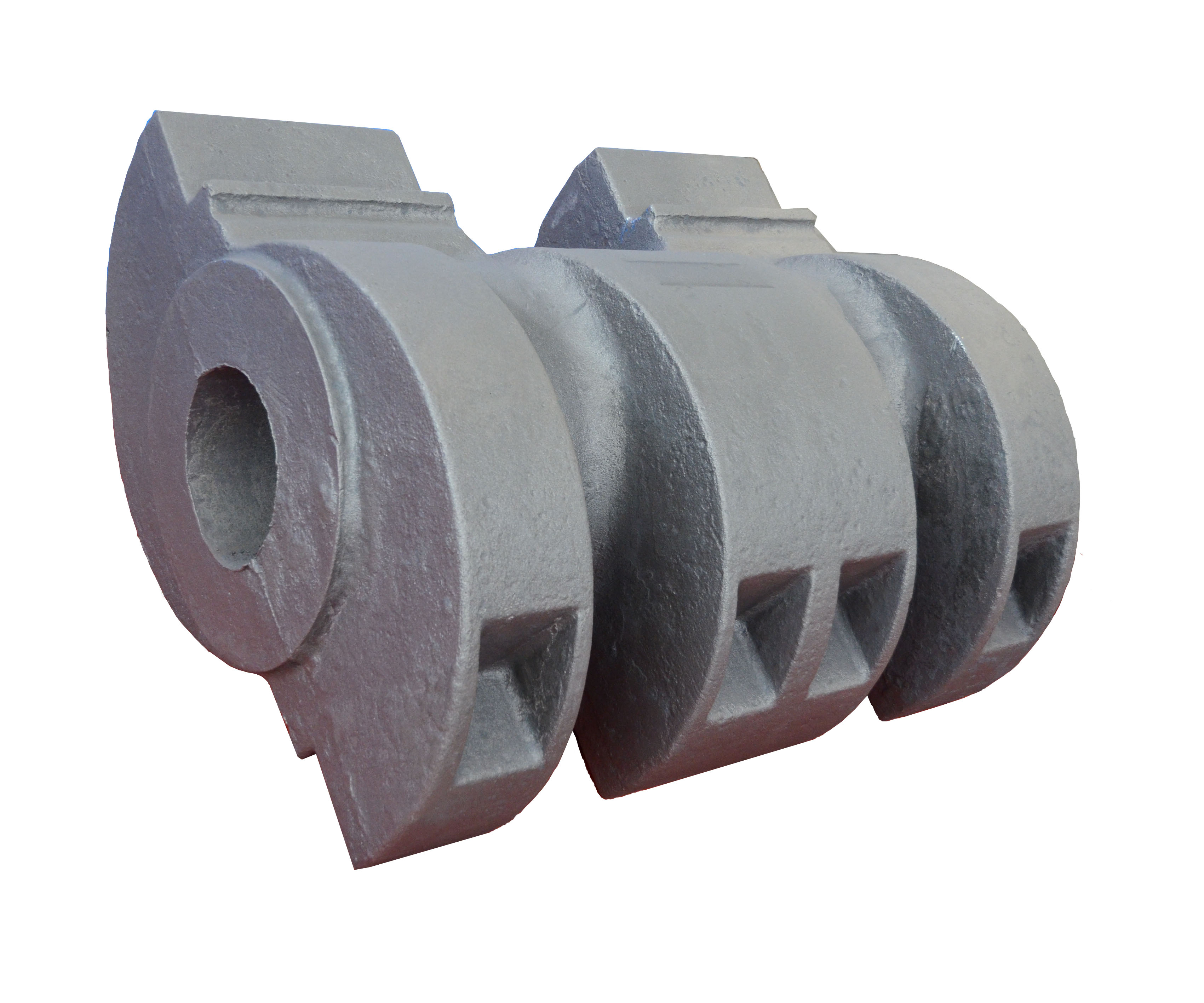

The Importance of Moulds and Pallets

In the production of SRC concrete pipes, the quality of moulds and pallets is essential. Moulds shape the concrete as it sets, ensuring that the final product meets specified dimensions and quality standards. Pallets, on the other hand, provide a stable base for curing and transporting these heavy concrete pipes. High-quality moulds and pallets are crucial for maintaining the efficiency and safety of the manufacturing process.

The Manufacturing Process

The production of SRC concrete pipes begins in factories where moulds are created from robust materials, typically steel or heavy-duty plastics. These moulds are designed to be reusable and must withstand the harsh conditions of concrete curing. The moulding process involves pouring a mixture of concrete and steel reinforcement into these moulds, followed by a curing phase that allows the material to set properly.

src concrete pipe mould pallet factories

Once the concrete has cured sufficiently, the moulds are removed, and the pipes are transported on pallets to ensure safe and efficient handling. Factories are increasingly adopting automated systems that streamline this process, reduce waste, and enhance productivity. The advanced technology employed in these factories not only improves the quality of the concrete pipes but also ensures that production meets the increasing demands of the construction industry.

Environmental and Economic Benefits

SRC concrete pipe mould pallet factories contribute to sustainability in construction. The use of recycled materials in the production of concrete mixes, along with efficient manufacturing processes, minimizes environmental impact. Additionally, SRC pipes have a long lifespan, reducing the need for frequent replacements and repairs.

Economically, these factories create jobs and stimulate local economies. They contribute to the infrastructure of communities by providing essential materials needed for construction projects. A robust supply chain for concrete pipes supports various sectors, including residential, commercial, and public works projects.

Future Trends

As technology continues to evolve, the production of SRC concrete pipes is likely to see further enhancements. Innovations such as 3D printing and advanced monitoring systems will probably emerge, optimizing the manufacturing process and improving product quality. Moreover, the ongoing focus on sustainability will likely push factories to adopt greener practices, further reducing their carbon footprint.

Conclusion

In conclusion, SRC concrete pipe mould pallet factories play a pivotal role in the construction industry by providing essential materials that meet the demands of modern infrastructure. Their commitment to quality, efficiency, and sustainability not only enhances the construction process but also contributes significantly to the well-being of communities. As the industry continues to evolve, these factories will remain at the forefront, driving innovations that will support sustainable development and infrastructure growth for years to come.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025