- африкалык

- Албанча

- Амхарча

- Арабча

- Армянча

- азербайжан

- Баскча

- Беларусча

- Бенгалча

- Бошнакча

- Болгарча

- Каталанча

- Себуано

- Кытай

- Кытай (Тайвань)

- Корсикче

- Хорватча

- Чехче

- Датча

- Нидерландча

- Англисче

- Эсперанто

- Эстончо

- Финче

- Франсузча

- фриз

- Галицияча

- Грузинче

- Немисче

- Грекче

- Гужаратиче

- Гаити креол

- Хаусача

- Гавайча

- Еврейче

- Жок

- Miao

- Венгерче

- Исландияча

- игбо

- Индонезияча

- Ирландча

- Итальянча

- Жапончо

- Жанавизче

- Каннадача

- Казакча

- кхмер

- Руанда

- Корейче

- күрд

- Кыргызча

- Эмгек

- Латынча

- Латвияча

- Литвача

- Люксембургча

- Македонияча

- Малгаши

- Малайча

- Малаяламча

- Малтизче

- Маориче

- Маратиче

- Монголчо

- Мьянма

- Непаличе

- Норвежче

- Норвежче

- Occitan

- Пуштунча

- Парсча

- Полякча

- Португалча

- Пунжабиче

- Румынча

- Орусча

- самоа

- Шотландиялык галец

- Сербче

- Англисче

- Shona

- Синдиче

- Sinhala

- Словакча

- Словенияча

- Сомаличе

- Испанча

- сундан

- Свахиличе

- Шведче

- Тагалогчо

- тажик

- Тамилче

- татар

- Телугуча

- Тайча

- Түркчө

- Түркмөнчө

- Украинче

- Урдуча

- уйгур

- Өзбекче

- Вьетнамча

- Валлийче

- Жардам

- Идишче

- Йорубача

- Зулуча

Jun . 13, 2025 10:53 Тизмеге кайтуу

Die Casting vs. Sand Casting: Which Aluminum Casting Service Suits Your Project Best?

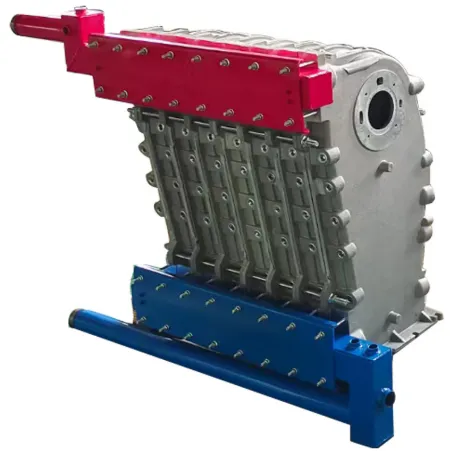

The manufacturing world relies heavily on aluminum casting to produce lightweight, durable, and complex components for industries ranging from automotive to aerospace. Two dominant methods—die casting and sand casting—offer distinct advantages depending on project requirements. This article compares these techniques through the lens of aluminum casting alloy selection, material aluminum castings properties, large aluminum casting capabilities, and types of aluminum casting processes. By understanding these factors, you can determine which method aligns with your project’s goals.

How Aluminum Casting Alloy Selection Impacts Die Casting and Sand Casting Performance

The foundation of any successful aluminum casting project lies in selecting the appropriate aluminum casting alloy. Alloys are tailored to meet specific mechanical, thermal, and corrosion-resistant demands, and their compatibility with die casting or sand casting varies significantly.

Die casting predominantly uses high-silicon alloys like A380 or A383. These alloys exhibit excellent fluidity, allowing them to fill intricate molds quickly under high pressure. This property is critical for producing thin-walled components with tight tolerances, such as electronic housings or automotive transmission cases. However, the rapid cooling inherent to die casting can limit the alloy’s ability to achieve optimal ductility, making it less ideal for parts requiring high impact resistance.

In contrast, sand casting favors alloys like A356 or 319, which contain magnesium or copper additives. These alloys solidify more slowly, enabling better stress distribution and reduced porosity in thicker sections. For instance, A356 is heat-treatable, enhancing its tensile strength and making it a preferred choice for structural components like aircraft brackets or engine blocks. The slower cooling rate of sand casting also allows for larger grain structures, improving fracture resistance in high-stress environments.

When choosing between methods, consider the alloy’s melting temperature, shrinkage behavior, and post-casting treatments. Die casting alloys often require minimal machining due to their smooth surface finish, whereas sand-cast parts may need additional grinding or heat treatment to meet final specifications.

Material Aluminum Castings: Balancing Strength and Surface Finish in High-Pressure Applications

The performance of material aluminum castings is deeply influenced by the casting method’s thermal and mechanical conditions. Die casting and sand casting produce components with divergent material properties, affecting their suitability for specific applications.

Die casting’s high-pressure injection process creates material aluminum castings with dense, non-porous structures. This results in superior surface finishes and dimensional accuracy, reducing the need for post-processing. However, the rapid cooling can introduce internal stresses, particularly in thicker sections. For example, thin-walled consumer electronics components benefit from die casting’s precision, but heavy-duty parts like hydraulic valve bodies may develop micro-cracks under cyclic loading.

Sand casting, on the other hand, uses slower cooling rates, which promote uniform solidification and minimize residual stresses. This makes material aluminum castings produced via sand casting more ductile and heat-resistant. Automotive piston heads, which endure extreme temperatures and mechanical loads, often rely on sand-cast aluminum alloys for their ability to withstand thermal fatigue. Additionally, sand casting accommodates a wider range of alloy compositions, enabling customization for specialized applications like marine hardware exposed to corrosive environments.

A critical trade-off lies in surface quality: die casting delivers near-net-shape parts with smooth surfaces, while sand casting may leave a rough texture requiring secondary machining. For projects prioritizing structural integrity over aesthetics, sand casting is often the better choice.

Producing Large Aluminum Casting Components: Die Casting Limits vs. Sand Casting Flexibility

Producing large aluminum casting components introduces unique challenges that influence the choice between die casting and sand casting. Size, weight, and cost considerations often tip the scale toward one method.

Sand casting excels in manufacturing large aluminum casting parts, such as aerospace wing brackets or industrial machinery frames. Its flexible mold-making process allows for virtually unlimited part sizes, limited only by the foundry’s capacity. Sand molds are also cost-effective for low-to-medium production runs, as they avoid the high tooling expenses associated with die casting. For example, a single sand mold for a turbine housing can be created at a fraction of the cost of a hardened steel die.

Die casting, while unmatched in speed and precision for small-to-medium parts, faces limitations with large aluminum casting due to machine size constraints and exorbitant mold costs. The high-pressure machines required for die casting have finite clamping forces and chamber sizes, making them impractical for components exceeding a few hundred pounds. However, advancements in vacuum-assisted die casting are bridging this gap for certain applications, such as automotive structural parts that demand both size and strength.

For projects requiring high-volume production of moderately sized large aluminum casting parts—like automotive engine mounts—die casting’s efficiency may justify initial investments. Conversely, sand casting remains the go-to for custom, oversized components with complex geometries.

FAQS:About Types of Aluminum Casting

What Are the Key Differences Between Die Casting and Sand Casting for Aluminum Casting?

Die casting uses reusable steel molds and high-pressure injection to produce high-volume, precision parts with smooth surfaces. Sand casting employs expendable sand molds for low-to-medium volumes, prioritizing flexibility and cost-effectiveness for large aluminum casting components.

How Does Aluminum Casting Alloy Affect the Choice of Casting Method?

Aluminum casting alloy properties, such as fluidity and heat tolerance, determine compatibility. High-silicon alloys suit die casting’s fast cycles, while heat-treatable alloys like A356 align with sand casting’s slower solidification for enhanced strength.

What Material Aluminum Castings Are Prone to Defects in Die Casting?

Thick-walled material aluminum castings in die casting may develop porosity due to rapid cooling. Sand casting’s slower solidification reduces this risk, making it preferable for bulky, high-integrity parts.

Can Large Aluminum Casting Achieve Tight Tolerances?

While sand casting has lower inherent accuracy, post-machining can refine large aluminum casting parts to meet tight tolerances. Die casting achieves precision upfront but is limited by part size.

What Types of Aluminum Casting Are Best for High-Stress Applications?

Sand-cast material aluminum castings with homogeneous grain structures excel in high-stress environments, such as aerospace components. Their slow cooling enhances mechanical properties critical for durability.

-

The Ultimate Choice for Optimal Thermal Exchange: Hex Heat Exchangers

ЖаңылыктарJun.24,2025

-

Hydronic Gas Boiler: The Efficient Heating Solution For Your Needs

ЖаңылыктарJun.24,2025

-

Discover the Efficiency of Mini Boiler Gas

ЖаңылыктарJun.24,2025

-

Concrete Pipe Mold Pallet Solutions

ЖаңылыктарJun.24,2025

-

Unveiling the Benefits of Light Pallet Mould

ЖаңылыктарJun.24,2025

-

Discover the Benefits of Ductile Cast Iron Pipe Mold Pallet

ЖаңылыктарJun.24,2025