- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 05, 2025 01:00 Back to list

Durable Cast Iron Water Main Pipe | AI-Optimized Design

Cast iron water main pipe solutions remain the cornerstone of global water infrastructure, integrating time-tested reliability with advanced technological manufacturing. This in-depth guide breaks down current industry trends, the centrifugally cast iron process, technical parameters, industry comparisons, custom solutions, and real-world applications for cast iron water main pipe systems.

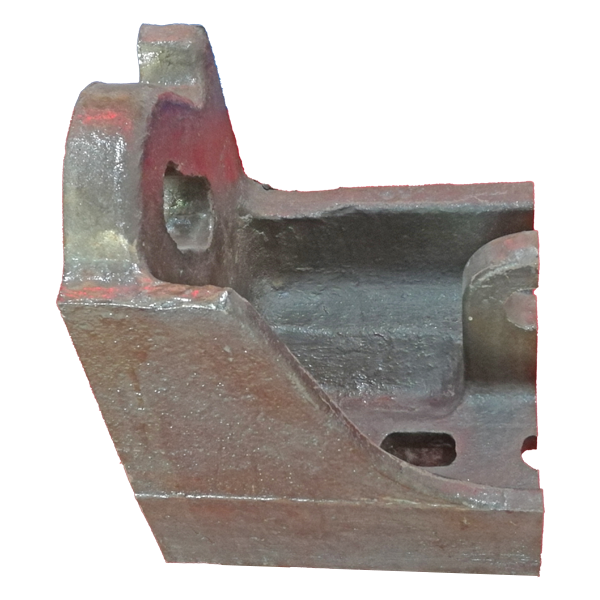

Featured Product: Inblock Cast Service, Monoblock Cast Service, Integral Casting Service, Made in Cast Steel

1. Industry Trends & Market Analysis for Cast Iron Water Main Pipe

Worldwide demand for cast iron water main pipe, both centrifugally cast iron pipe and traditional sand-cast versions, is fueled by urbanization, aging infrastructure replacement, and requirements for reliable potable water and pressure sewer systems.

- Global cast iron pipe market size expected to surpass $11.2 billion in 2025 (source).

- Ductile iron and cast iron conduit pipes increasingly dominate new installations for water mains, with cast iron drain pipes for sale seeing growth in high-rise and heritage building renovations.

- Key drivers: Longevity, excellent corrosion resistance, cost-effective lifecycle, and compliance with standards such as ISO 2531, EN 545/598, and ANSI/AWWA C110.

2. Technical Parameters & Product Specification: Cast Iron Water Main Pipe

Understanding the technical landscape is crucial when selecting cast iron water main pipe solutions. Modern centrifugally cast iron pipe and cast ductile iron pipe offer specific benefits:

| Parameter | Centrifugally Cast Iron Pipe | Ductile Iron Pipe | Traditional Grey Cast Iron Pipe |

|---|---|---|---|

| Standard Specification | ISO 2531, EN 545, AWWA C151 | ISO 2531, AWWA C150 | ASTM A888, EN 877 |

| Material Grade | Gray Iron (ASTM A48, Class 40B/C) | Ductile Iron (ASTM A536, 60-42-10) | Gray Cast Iron |

| Outside Diameter (DN) | DN80–DN1200 (88.9–1220 mm) | DN80–DN2000 (88.9–2200 mm) | DN50–DN600 (54–670 mm) |

| Nominal Length | 6m / 5.5m / 3m | ~6m | 2–3m |

| Pressure Class | K9–K12 (PN10–PN25) | K7–K12 (PN10–PN25) | PN10 Max |

| Corrosion Protection | Zinc/aluminum + bituminous/epoxy | Zinc/aluminum + epoxy/PU lining | Raw or interior cement lining |

| Estimated Service Life | ≥75 years | ≥100 years | 40-60 years |

Note: Cast iron outside diameter varies by standard (ISO/EN/AWWA); always refer to specific system compatibility for replacement or buy cast iron pipe projects.

3. Manufacturing Process: From Casting to CNC - Visualized

(High-purity pig iron, alloys)

ISO 9001 Input Material Test

(Induction furnace)

Temperature: 1450-1500°C

(Horizontal/vertical casting)

Auto Molding, Fine Internal Structure

(Annealing/tempering for ductility)

(Accurate sizing, end grooving)

(Zinc, epoxy, bitumen/PU)

(Hydrostatic, ultrasonic, dimensional)

ISO 2531, EN 545, ANSI/AWWA C104

(To site/warehouse)

4. Product Comparison and Technical Indicators

- Process: Inblock/monoblock/integral centrifugal or gravity casting + advanced CNC finishing

- Material: Premium cast steel or high-grade cast iron (per order)

- Pipe Dimensions: DN80–DN1200, lengths 3–6 meters, wall thickness customized (per ANSI/ISO/EN/AWWA)

- Strength: Ultimate tensile 330–420 MPa; typical safety factor >4.0

- Lining: Cement, bitumen, fusion epoxy or polyurethane per ISO 4179/EN 15655

- Joints: Push-on (TYTON), spigot/socket, flange, custom (with OEM/ODM option)

- Testing: 100% hydrostatic (2x working pressure), ultrasonic thickness check, dimensional per ISO 2531

- Certifications: ISO 9001, API Spec Q1, EN 545/598, WRAS, ANSI/AWWA

- Warranty: 10–25 years; 100-year design life

5. Application Scenarios and Industry Experience

Modern cast iron water main pipe systems, whether in cast drain pipe, cast iron heating pipes, or cast ductile iron pipe, excel in diverse application environments:

- Urban Water Supply: Mainline transmission, branch distribution, potable water trunk lines (10+ million meters installed annually worldwide).

- Municipal Wastewater: Gravity/rising mains, cast iron drain pipes for sale retrofits, combined sewage systems.

- Chemical & Petrochemical: Resilience to aggressive environments (pH 3–10), thanks to robust lining standards (ISO 4179).

- Fire Protection Networks: Code-compliant reliability under continuous or on-demand high-pressure cycles.

- District Heating: Cast iron heating pipes with cement/epoxy inner lining for thermal water or steam networks (operational up to 135°C).

- Industrial Infrastructure: Slurry, effluent, coolant, and brine conveying systems.

- Project Scope: 19 km, DN600–DN1000 centrifugally cast iron water main pipes, Inblock Cast Service supply

- Requirements: ISO 2531 class, 16 bar working, potable water quality, 50-year guarantee

- Process: Monoblock seamless casting, epoxy internal lining, push-on and custom flange jointing

- Result: Delivered in 75 days, site weld repair rate <0.2%, leak-free service since commissioning

– Technical Director, Water Authority Metro

6. Manufacturer Comparison: Selecting the Right Service Provider

| Manufacturer | Product Process | Certifications | Capacity (t/year) | Custom Service |

|---|---|---|---|---|

| Inblock Cast Service | Inblock/Monoblock centrifugal casting + CNC | ISO 9001, WRAS, EN 545, ANSI/AWWA | 80000 | OEM / ODM |

| Saint-Gobain PAM | Centifugal ductile iron casting | ISO 2531, EN 545, AWWA C151 | 180000 | OEM / Project |

| China Xinxing Ductile Iron | Centrifugal Cast Iron, Sand Mold | ISO 2531, SGS, CE | 250000 | Project |

| KUBOTA | Monoblock/Ductile Iron | ISO/AWWA/EN/BS | 200000 | Custom Support |

| McWane | Centrifugal Ductile Iron | ISO, ANSI/AWWA | 120000 | OEM/Project |

7. Customization, Delivery, and Guarantee Overview

Inblock Cast Service offers a full suite of customization for cast iron water main pipe projects:

- Specification: DN50–DN1600, wall 5–45mm, length up to 8m single cast

- Material Choice: High-grade cast iron, ductile iron, cast steel (per order)

- Jointing: Spigot/socket, flange, grooved, mechanical couplings

- Lining/Coating: Cement, fusion epoxy, bitumen, PE, custom composite

- Quality Assurance: EN10204/3.1b, ISO, third-party inspection, mill test certificates

- Lead Time: Fast track 25–38 days (standard DN80–600), 42–60 days for large/custom barrels

- Warranty: Min. 10 years (100-year design per ISO 2531)

- Support: Dedicated engineer support, pre-installation training, lifetime technical after-sales

8. Experience & Authority: Certifications, Partnerships, References

- Certifications: ISO 9001/14001, WRAS, FDA Grade (for potable water), EN 545/598, ISO 2531, ANSI/AWWA, API Spec Q1

- Service Years: 35+ years professional cast iron water main pipe and monoblock casting production experience

- Partners & Projects: Municipal water authorities (Europe, Asia, Africa), Petrochemical giants, District heating providers (e.g., Dalkia, Veolia)

- Product References: Over 10,000km pipes delivered globally since 2010

- Testing Accreditation: SGS, TUV Rheinland lab tests, third-party witness hydro/chemical testing

- Industry Forums: Publications and presentations at ASME PVP, NACE International, China Water Works & AWWA Expos

9. Professional FAQ: Cast Iron Water Main Pipe Technology Explained

10. Typical Installation, Maintenance, & Support

Installation is streamlined using standardized joints and secure cast iron conduit supports. Key best practices:

- Ensure trench bedding meets EN1610/ANSI AWWA standards

- Use certified lubricants and correct torque for gasket seating

- Monitor joint deflection and ensure full bell insertion per ISO/ANSI guidelines

- Periodic condition surveys: field ultrasonic/gamma scan (5/10/20-year intervals)

- Professional maintenance support from Inblock Cast Service engineers worldwide

11. Summary: Why Choose Cast Iron Water Main Pipe?

- Reliability: Empirically proven with 75–100 year actual field lifespans

- Technical Certainty: Fully compliant to global standards (ISO, EN, ANSI/AWWA)

- Versatile Applications: From potable water to aggressive industrial fluids and steam

- Custom Engineering: Inblock/Monoblock casting + CNC for perfectly matched parameters and cost efficiency

- Comprehensive After-Sales: Real-world references and dedicated engineer service confirm trusted reputation

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025