- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 30, 2025 03:00 Back to list

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

Explore everything about cast iron water main pipe, including process technology, technical data, applications in modern industries, and why DIN EN877 cast iron pipes from original Chinese factories set the benchmark for quality and reliability.

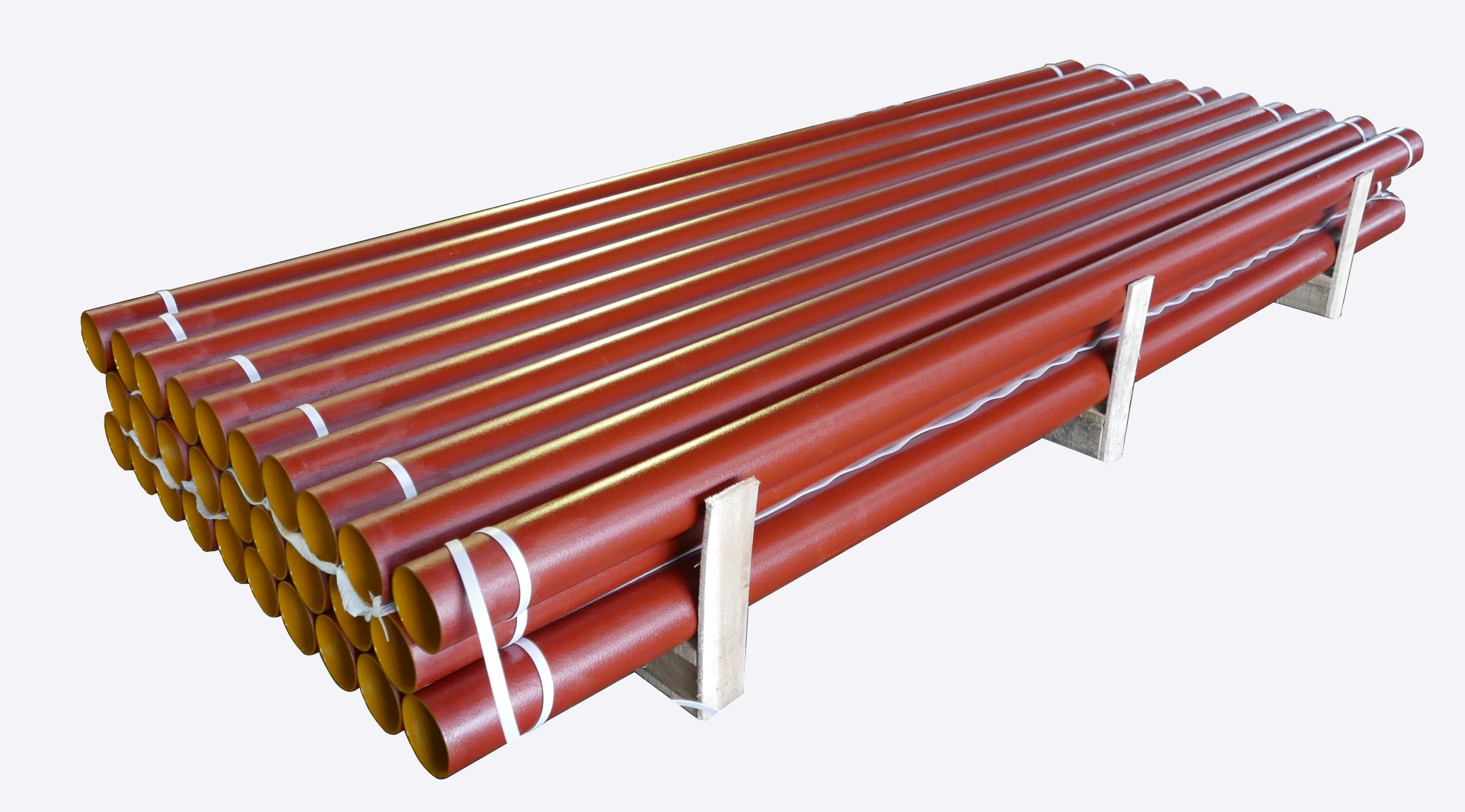

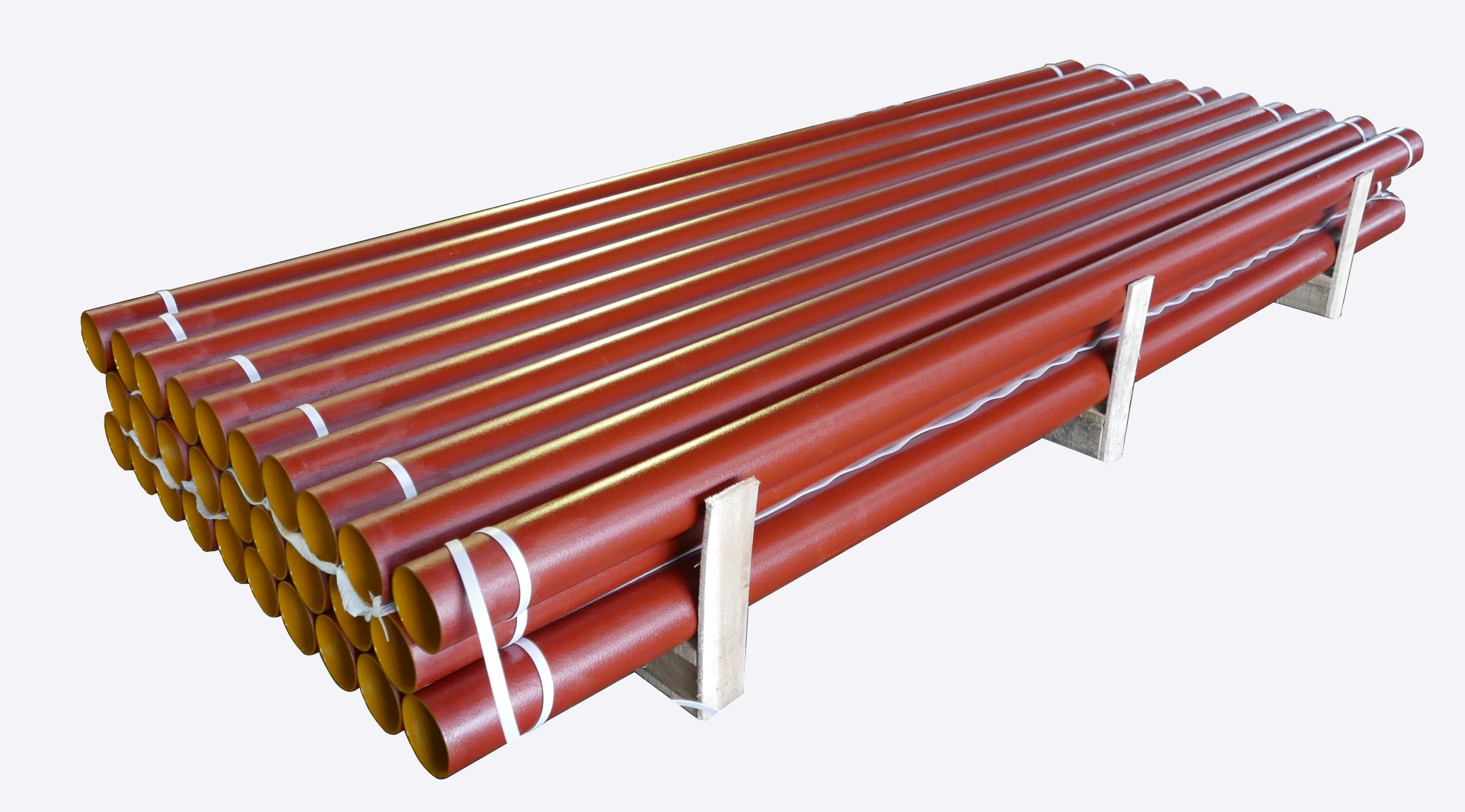

Figure: High-performance cast iron water main pipe deployed in municipal projects

Industry Trends: Cast Iron Pipes in Water Infrastructure

The global water infrastructure market has consistently relied on cast iron water main pipe for over a century. Recent studies by MarketsandMarkets project the ductile and gray cast iron pipe market to reach USD 12.3 billion by 2027 (source), with Asia-Pacific, particularly China, driving growth through extensive urban development.

Key industry drivers:

Key industry drivers:

- Urban expansion and modern renewal of water supply networks

- Superior corrosion resistance and durability compared to alternatives

- Stringent adherence to ISO 2531, EN 877, and ANSI A21.6 quality standards

- Increased replacement of aged supply lines with ductile/cast iron upgrades

- Growing demand for customized, high-performance water main pipe systems

Centrifugally cast iron pipes with protective coatings for water transportation

What Is a Cast Iron Water Main Pipe? Key Types & Technical Parameters

Cast iron water main pipes are pressure or gravity-flow pipes formed from molten iron using centrifugal casting or sand casting. They are further classified as:

- Centrifugally cast iron pipe – for superior strength and uniform wall thickness.

- Bell and spigot ductile iron pipe – for easy joining and pressure applications.

- Gray cast iron/conduit/ductile iron pipes – distinguished by graphite structures (ferrite/pearlite matrix for ductility or flake graphite for traditional gray iron).

- High compressive strength (180-300MPa)

- Robustness for buried and exposed installations

- Excellent longevity (factory tests verify >50 years in-service life)

- Low hydraulic friction and high flow capacity

"Bell and spigot ductile iron pipe" joint system with push-fit connection

Parameter Comparison Table: Cast Iron & Ductile Iron Pipes

| Specification | Gray Cast Iron Pipe | Ductile Iron Pipe | PVC/Plastic Pipe |

|---|---|---|---|

| Manufacturing Process | Centrifugal/Sand Casting | Centrifugal Casting | Extrusion/Molding |

| Tensile Strength (MPa) | 150–200 | 420–560 | 50–90 |

| Service Life (Years) | 40–70 | 50–100 | 10–30 |

| Corrosion Resistance | Very Good (with lining) | Excellent (with lining) | Moderate |

| Pressure Rating (bar) | Up to 16 | Up to 64 | Up to 16 |

| Standard Compliance | ISO 2531/EN877 | ISO 2531/EN545 | ISO 1452 |

| Applications | Drainage, Sewer | Water Main, Gas | Drainage |

Process Flow: How Are Cast Iron Water Main Pipes Manufactured?

Raw Material Inspection

Premium pig iron, recycled steel, and ferroalloys undergo chemical & physical testing.

Premium pig iron, recycled steel, and ferroalloys undergo chemical & physical testing.

Key Standard: ISO 2591

⇨

Melting & Alloying

Charge is heated in an induction furnace to 1450–1500°C; composition adjusted for strength & ductility.

Charge is heated in an induction furnace to 1450–1500°C; composition adjusted for strength & ductility.

⇨

Centrifugal Casting

Melt is spun in a rotating mold, forming dense, uniform pipe walls.

Melt is spun in a rotating mold, forming dense, uniform pipe walls.

ISO 2531/EN877 Certified

⇨

CNC Machining & Surface Treatment

Pipe ends are beveled, and coatings are applied (epoxy, zinc, or cement mortar lining) for corrosion protection.

Pipe ends are beveled, and coatings are applied (epoxy, zinc, or cement mortar lining) for corrosion protection.

⇨

Non-Destructive Testing

Ultrasonic, hydrostatic, and visual checks; ensures zero leakage as per EN 877/ISO 8572.

Ultrasonic, hydrostatic, and visual checks; ensures zero leakage as per EN 877/ISO 8572.

⇨

Packing & Final QC

Each pipe is labeled, bundled, and sampled for dimension/pressure compliance.

Each pipe is labeled, bundled, and sampled for dimension/pressure compliance.

Centrifugal casting of cast iron water main pipe (Key to uniform wall thickness and defect-free structure)

CNC finishing of cast iron & ductile iron pipe spigots ensures precise fit for installation.

Download Process Video:

Technical Parameters of DIN EN877 Cast Iron Pipes and Fittings

Shortlisted for demanding projects globally, DIN EN877 Cast Iron Pipes and Fittings feature robust technical parameters:

Material: Gray cast iron (minimum tensile strength: 200 MPa)

Diameter Range: DN 50mm – DN 600mm

Wall Thickness: 3.5mm–7mm (as per EN877 class)

Coating System: Epoxy-resin and cement mortar internal lining (protects against acidic/alkaline water)

Testing Standard: EN877/ISO6594 Hydrostatic test (1.5x working pressure)

Expected Service Life: ≥50 years (lab tested, real-world cases over 80 years)

Certifications: ISO 9001:2015, ISO 14001, FM APPROVED

Applicable Industries: Water supply, wastewater, petrochemical, metallurgy, tunneling & drainage.

Material: Gray cast iron (minimum tensile strength: 200 MPa)

Diameter Range: DN 50mm – DN 600mm

Wall Thickness: 3.5mm–7mm (as per EN877 class)

Coating System: Epoxy-resin and cement mortar internal lining (protects against acidic/alkaline water)

Testing Standard: EN877/ISO6594 Hydrostatic test (1.5x working pressure)

Expected Service Life: ≥50 years (lab tested, real-world cases over 80 years)

Certifications: ISO 9001:2015, ISO 14001, FM APPROVED

Applicable Industries: Water supply, wastewater, petrochemical, metallurgy, tunneling & drainage.

Rigorous full-length hydrostatic testing as per EN877 for every batch

Product Specification Table: DIN EN877 Cast Iron Pipes

| Model | Nominal Diameter (DN) | Wall Thickness (mm) | Max Working Pressure (bar) | Length (m) | Coating System | Weight (kg/m) |

|---|---|---|---|---|---|---|

| EN877-GC50 | 50 | 3.5 | 10 | 3 | Epoxy+Zinc+Mortar | 6.6 |

| EN877-GC100 | 100 | 3.5 | 10 | 3 | Epoxy+Zinc+Mortar | 12.6 |

| EN877-GC200 | 200 | 4.0 | 10 | 3 | Epoxy+Zinc+Mortar | 25.5 |

| EN877-GC300 | 300 | 5.0 | 8 | 3 | Epoxy+Zinc+Mortar | 48.8 |

* Values above are typical for China Original Factory standard product. Custom sizes & thicknesses available, please inquire for tailored solutions.

DIN EN877-compliant cast iron drain pipes for sale

Data Visualization: Comparative Performance

*Data sourced from ISO 2531/EN877 reports and third-party laboratory testing (2023, CASITING)

Visual analysis for clients comparing to buy cast iron pipe over alternatives

*Worldwide urban pipeline market share (%) by product category, 2023

Why Choose DIN EN877 Cast Iron Pipes from China Original Factory?

When looking to buy cast iron pipe or buy ductile iron pipe, technical and commercial factors distinguish reputable suppliers:

- Rigorous Material Certification: ISO 9001:2015, EN 877, FM/UL/FM/CE certified for global tenders

- Manufacturing Scale: Automated centrifugal lines, multi-size flexibility, fast lead times

- Quality Control: 100% hydrostatic + eddy current + X-ray NDT for zero-defect supplies

- Custom Solutions: Non-standard diameter/length, special jointing (GSV, K-type) for industrial requirements

- Logistics Support: Global export, marine-grade packaging, on-site technical advisory

Batches of cast ductile iron pipe packaged for international deployment

Manufacturer Comparison Table

| Supplier | Standard | Capacity (Tons/Year) | Min. Lead Time | After-Sales Support | Major Projects |

|---|---|---|---|---|---|

| CASITING (China Original Factory) | DIN EN877, ISO9001, FM UL | 80,000 | 16 days | 5 years, global | Beijing Subway, Total (Petrol), IKEA HQ |

| PAM Saint-Gobain (France) | EN545, EN877 | 120,000 | 30 days | Europe, MENA regions | Paris Water Utility, Madrid Metro |

| McWane Inc. (USA) | ANSI A21.6, ISO2531 | 100,000 | 25 days | US, Canada | Los Angeles Water, Rio Sewerage |

*Data compiled from manufacturers' 2023 annual reports.

Large-scale water main projects prefer buy ductile iron pipe options for their superior safety margins.

Custom Solutions & Application Scenarios

Customizing your cast iron water main pipe:

- Non-standard diameter (up to 750mm), thickness, and lengths available on request

- Epoxy, ceramic or zinc-rich coatings for harsh environments (chemical, marine)

- Jointing: hub&spigot, push-fit, or mechanical couplings (for difficult-access zones)

- Integrated sensors/liners for smart pipeline monitoring and leak detection

- OEM fit to international standards: EN877, ISO 6594, ASTM A888, BS EN598

- Municipal water main and branch pipelines

- Underground sewage and drainage systems (urban and industrial)

- Oil & gas pipeline conduit (sleeving and protection)

- Subway, airport, and highway tunnel drainage

- Fire fighting distribution and recycled water systems

"Cast drain pipe" as firewater main at international airport terminal

Real-World Application Cases & User Feedback

Project: Beijing International Airport (2022 Retrofit)

- Scope: 12,000m EN877 cast iron water main pipe DN200 with VJ coupling

- Results: Zero leakage over 12 months under 5.5 bar constant pressure

- Reference: China Urban Drainage Association

- Product: DN150/250 gray cast iron, hubless

- Installer Feedback: "Smooth cutting, optimal internal lining, twice as fast installation vs steel pipe"

- Product: Customized DN300-400, cement-mortar lined, for chemical wastewater

- Performance: Excellent chemical resistance & pipe joint reliability, far exceeding PVC alternative’s lifetime

"Cast iron conduit" used in petrochemical plant for cable protection

Field installation of cast iron drain pipes for sale – minimal sealing failures reported by contractors

FAQ: Professional Questions about Cast Iron Water Main Pipe

1. What base material is used for DIN EN877 cast iron water main pipes?

High-purity gray cast iron, compliant with EN-GJL-150 or EN-GJL-200 standards. Metallurgy ensures flake graphite structure for optimal damping and corrosion resistance.

2. What surface coatings are available for extended lifespan?

Standard pipes feature a two-layer system: internal cement mortar or epoxy lining; external zinc-rich primer and polyurethane or epoxy coating, certified by ISO 12944 for corrosion protection zones up to C5.

3. What jointing systems are supported?

Bell and spigot, hubless couplings (EN877 compliant), mechanical (MJ, flange, push-on) and bespoke rubber-gasketed joints for pressurized lines.

4. How are pipes tested for safety and compliance?

EN877/ISO 6594 mandates hydrostatic pressure testing at 1.5x rated working pressure, X-ray and ultrasonic NDT of welds/ends, and full traceable batch QC documentation.

5. Can pipes be used with aggressive wastewaters?

Yes. For industrial/wastewater applications, pipes are specified with acid- and alkali-resistant cement or fusion-bonded epoxy lining, exceeding EN 877 appendix E requirements.

6. Are there specific installation standards?

All cast iron water main pipe installations must follow ISO 10803 and EN 877:2023, ensuring correct bedding, jointing, and corrosion protection for 50+ years of safe operation.

7. What after-sales or warranty support is included?

China Original Factory provides a 5-year full product warranty and lifetime technical consultation. Global onsite support is available for large-scale projects.

Delivery, Warranty & After-Sales Support

- Production Lead Time: Normally 10–20 days from order confirmation (rush for urgent projects available)

- Warranty: Minimum 5 years full warranty against structural failure, 20+ years expected maintenance-free performance in potable water systems

- Technical Consulting: Engineering team provides specification review, on-site support, and 3D drawing services

- Sample Policy: Free samples (up to 1.5m) available for lab testing and field qualification

- Contact: Direct Quote/Support

Finished cast iron water main pipe shipment ready for global delivery

Summary & Further Resources

According to industry experts at the Eng-Tips Structural Engineering Forum and the 2023 edition of "Journal of Urban Water," cast iron water main pipe remains irreplaceable for mainline projects demanding exceptional longevity, corrosion resistance, and load handling—attributes proven in installations over the last 100+ years. For deeper technical reading, see: ASCE Journal of Urban Water.

Share

Next:

This is the last article

Latest news

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025