- afrikanesch

- Albanesch

- Amharesch

- Arabesch

- Armenesch

- Aserbaidschan

- Baskesch

- wäissrussesch

- Bengalesch

- Bosnesch

- Bulgarescg

- katalanesch

- Cebuano

- China

- China (Taiwan)

- korsesch

- Kroatesch

- Tschechesch

- Dänesch

- Hollänesch

- Englesch

- esperanto

- Estonesch

- Finnesch

- Franséisch

- friesesch

- Galizesch

- Georgesch

- Däitsch

- Griichesch

- Gujarati

- Haitescht Creole

- Haussa

- Hawaianesch

- Hebräesch

- Nee

- Miao

- Ungaresch

- Islännesch

- igbo

- Indonesesch

- Iresch

- Italienesch

- Japanesch

- Javanesesch

- Kannada

- kasachesch

- Khmer

- Rwandaner

- Koreanesch

- kurdesch

- kirgisesch

- Aarbecht

- laténgesch

- Lettesch

- litauesch

- lëtzebuergesch

- Mazedonesch

- Malgashi

- Malaiesch

- Malajalam

- Maltesesch

- maoresch

- Marathi

- mongolesch

- Myanmar

- Nepalesesch

- Norweegesch

- Norweegesch

- Okzitanesch

- pashtu

- Persesch

- Polnesch

- Portugisesch

- pundschabi

- Rumänesch

- Russesch

- Samoanesch

- Schottesch Gaelesch

- serbesch

- Englesch

- Shona

- Sindhi

- Sinhala

- Slowakesch

- Slowenesch

- somalesch

- Spuenesch

- Sundanesesch

- Swahili

- Schweedesch

- Tagalog

- Tadschikesch

- Tamil

- Tataresch

- Telugu

- Thai

- tierkesch

- turkmenesch

- Ukrainesch

- Urdu

- Uighur

- Usbekesch

- Vietnamesesch

- Waliser

- Hëllef

- jiddesch

- Yoruba

- Zulu

Mar . 10, 2025 13:59 Zréck op d'Lëscht

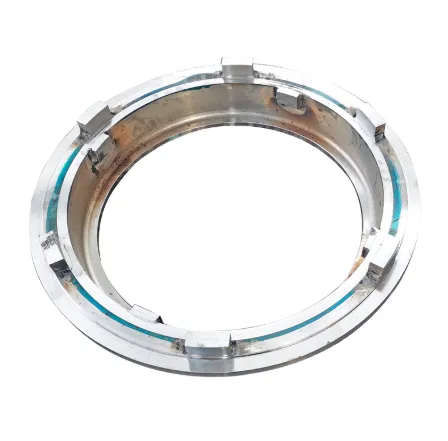

Key Factors to Consider When Buying Cast Iron Pipe Mold Pallets

When it comes to selecting the right cast iron pipe mold pallet, several important factors need to be considered to ensure the best results in pipe production. From strength and durability to compatibility with various molds, choosing the right pallet plays a pivotal role in the efficiency and quality of the pipes produced. Here's a closer look at the key aspects to keep in mind when purchasing cast iron pipe mold pallets, especially those designed for cement pipe production.

Strength and Durability of Cast Iron Pipe Mould Pallets

One of the most important factors to consider when selecting a cast iron pipe mold pallet is its strength and durability. Since these pallets will be used to support heavy loads during the molding process, they must be capable of withstanding the pressure and weight of the concrete or cement. The stamp cement pipe mould pallet is specifically designed to handle the high pressures involved in the casting process without compromising on strength.

A stamp cement pipe mold pallet made from high-quality cast iron is capable of resisting wear and tear, ensuring that it remains in optimal condition even after prolonged use. This durability is crucial in preventing costly repairs and ensuring the efficiency of your production line. Be sure to choose a pallet that can handle the weight and pressure your molds will encounter.

Cast Iron Pipe Mold Pallets:Compatibility with Molding Equipment and Processes

The stamp cement pipe mold pallet or punch cement pipe mold pallet should also be compatible with the type of molding equipment and processes being used in your production. These pallets are available in various designs, such as punch cement pipe mould pallet, which may work better with specific types of equipment that require a certain level of precision and support.

When selecting the right punch cement pipe mould pallet, consider the type of cement pipe being produced and the machinery you are using. Molds need to fit perfectly within the pallet to ensure that the pipes are cast uniformly, without any deformation or inconsistency. Understanding the technical compatibility of your pallet with your molding machinery will help ensure that the entire production process runs smoothly and efficiently.

Cost-Effectiveness and Long-Term Investment with Cast Iron Pipe Mold Pallets

While the initial cost of purchasing cast iron pipe mold pallets may be higher than alternatives made from other materials, they are an investment that can offer long-term savings. A stamp cement pipe mould pallet made from cast iron is designed to endure the rigors of heavy-duty use, reducing the need for frequent replacements. This makes them more cost-effective in the long run.

The durability of punch cement pipe mold pallets ensures that they continue to function well over an extended period, which in turn helps maintain the quality and consistency of your production. Since these pallets last longer and require fewer repairs, the long-term savings far outweigh the initial investment.

Cast Iron Pipe Mold Pallets:Customization Options for Specific Production Needs

Another key factor to consider is whether the cast iron pipe mold pallet can be customized to suit the specific needs of your production process. Some manufacturers may require special features such as specific dimensions or unique mold designs to meet the unique demands of their pipe production lines.

Choosing a punch cement pipe mold pallet with customization options allows you to fine-tune the pallet to your requirements, ensuring better performance and increased efficiency. Whether it's adjusting the thickness or enhancing the mold release features, customization ensures that the pallet supports the specific needs of your manufacturing process.

Lastly, it's crucial to consider the maintenance and care requirements of the cast iron pipe mould pallet to ensure its longevity. Cast iron molds, while highly durable, still require regular maintenance to keep them functioning at peak efficiency. Cleaning and inspecting the pallets after each use, as well as checking for wear and tear, will help extend their life and prevent costly downtime.

For example, punch cement pipe mold pallets may need to be treated with special coatings or cleaned using specific methods to maintain their resistance to corrosion and wear. Proper care ensures that the pallet continues to meet the demanding requirements of cement pipe production, ultimately helping your business maintain high levels of productivity and efficiency.

In conclusion, selecting the right cast iron pipe mold pallet involves a careful assessment of factors such as strength, durability, compatibility with equipment, cost-effectiveness, and customization options. By considering these elements, you can ensure that your investment in punch cement pipe mould pallets or stamp cement pipe mold pallets delivers long-term benefits in terms of quality and production efficiency. For high-quality, reliable products tailored to your needs, visit our website to explore our selection of cast iron pipe mould pallets.

-

The Ultimate Choice for Optimal Thermal Exchange: Hex Heat Exchangers

NeiegkeetenJun.24,2025

-

Hydronic Gas Boiler: The Efficient Heating Solution For Your Needs

NeiegkeetenJun.24,2025

-

Discover the Efficiency of Mini Boiler Gas

NeiegkeetenJun.24,2025

-

Concrete Pipe Mold Pallet Solutions

NeiegkeetenJun.24,2025

-

Unveiling the Benefits of Light Pallet Mould

NeiegkeetenJun.24,2025

-

Discover the Benefits of Ductile Cast Iron Pipe Mold Pallet

NeiegkeetenJun.24,2025