ພ.ຈ. . 25, 2024 11:18 Back to list

aluminum silicon alloy

Aluminum-Silicon Alloys Composition, Properties, and Applications

Aluminum-silicon alloys, commonly referred to as Al-Si alloys, are a class of materials widely used across various industries due to their exceptional properties and versatility. These alloys are primarily composed of aluminum, with silicon being the most significant alloying element. The addition of silicon enhances the mechanical properties of aluminum while also imparting improved castability and corrosion resistance.

Composition and Types

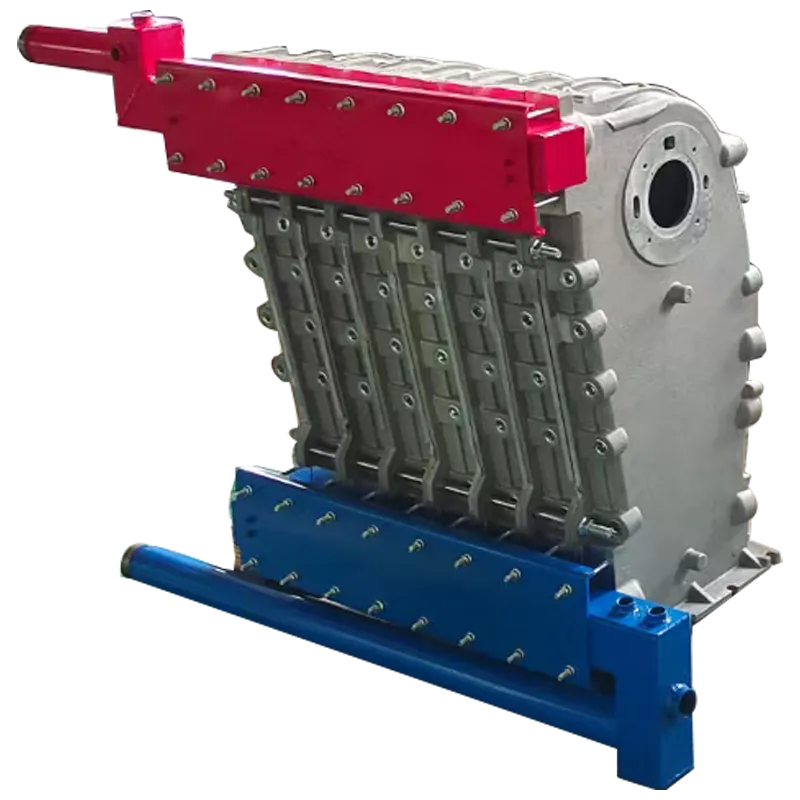

Aluminum-silicon alloys can be categorized into two main types wrought and cast alloys. The wrought Al-Si alloys are typically used in applications that require excellent mechanical properties and are often subjected to processing methods like rolling or forging. Cast Al-Si alloys, on the other hand, are primarily used in applications where complex shapes and high dimensional stability are essential, such as automotive engine components and complex housings.

The silicon content in these alloys usually ranges from 1% to 12%. Lower silicon concentrations (1%-5%) impart improved ductility and strength, making them suitable for applications requiring excellent mechanical performance. Higher silicon levels (5%-12%) create a strong alloy that provides enhanced wear resistance and lower thermal expansion, which are vital characteristics in engine blocks and cylinder heads.

Properties

One of the notable features of aluminum-silicon alloys is their excellent fluidity. This property allows for intricate cast designs, making them ideal for complex geometries. Moreover, the presence of silicon enhances the alloy's resistance to thermal and mechanical stress, which is crucial in high-temperature applications.

aluminum silicon alloy

Al-Si alloys demonstrate low density and high strength-to-weight ratios, making them suitable for lightweight structural applications. Their good corrosion resistance is attributed to the passive oxide layer that forms on the alloy's surface, protecting the metal from environmental degradation. Furthermore, the alloys display good electrical conductivity and are well-suited for applications requiring specific electrical performance characteristics.

Applications

The applications of aluminum-silicon alloys are vast and span multiple industries. In the automotive sector, these alloys are commonly used for manufacturing engine components, such as cylinder heads, engine blocks, and pump housings. Their lightweight nature contributes to improved fuel efficiency, while their heat resistance allows for reliable performance in high-temperature environments.

In the aerospace industry, Al-Si alloys are chosen for their low weight and strength characteristics, making them ideal for structural components and components that must withstand extreme conditions. The electrical and electronics industries also utilize these alloys for their excellent conductivity, particularly in the manufacturing of connectors and other electronic components.

Moreover, the casting capabilities of aluminum-silicon alloys make them ideal for producing complex shapes in various consumer products, including kitchenware, machinery parts, and decorative items. The ability to create intricate designs while maintaining material integrity is a significant advantage.

Conclusion

In conclusion, aluminum-silicon alloys are a critical material in modern engineering and manufacturing practices. Their favorable properties—such as excellent castability, low density, high strength, and good corrosion resistance—make them suitable for a wide range of applications. As technology advances, the potential for new applications continues to grow, ensuring that aluminum-silicon alloys remain vital components in various industries for years to come. Whether in automotive, aerospace, or consumer products, the importance of these alloys cannot be overstated, and their continued development promises to enhance the capabilities of modern engineering.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025