ສ.ຫ. . 06, 2025 00:40 Back to list

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

The Unseen Backbone of Modern Cities: The Role of Cast Iron Pipes

Beneath our bustling cities lies a critical network that sustains life and industry: the water distribution system. For over a century, the material of choice for this vital infrastructure has been iron. The journey from traditional gray cast iron to today's high-tech centrifugally cast iron pipe—specifically ductile iron—is a story of remarkable engineering advancement. This evolution has solidified its position as the premier material for cast iron water main pipe systems, prized for its unparalleled strength, longevity, and reliability.

Industry trends now gravitate towards sustainability and "smart" infrastructure. Modern ductile iron pipes are not only made from a high percentage of recycled materials but their long service life (often exceeding 100 years) reduces the environmental and economic impact of frequent replacements. According to a market analysis by Grand View Research, the global iron and steel pipes market is projected to grow, driven by escalating water infrastructure demands worldwide. This underscores the continued relevance and critical importance of robust piping solutions.

Understanding the nuances of this material—from the cast iron outside diameter to its pressure ratings—is crucial for engineers, contractors, and municipal planners. This guide will provide a comprehensive overview, covering everything from the manufacturing process and technical specifications to application scenarios and how to buy cast iron pipe that meets stringent international standards.

From Molten Iron to Mighty Pipe: The Manufacturing Process Unveiled

The superior quality of a modern cast iron water main pipe is not accidental; it is the result of a highly controlled and sophisticated manufacturing process. The primary method used today is centrifugal casting, also known as the de Lavaud process. This technique ensures a pipe wall with a dense, uniform grain structure, free from the impurities and gas pockets that can plague static castings.

The Centrifugal Casting Journey

The transformation from raw materials to a finished pipe involves several critical stages, each governed by strict quality control measures adhering to standards like ISO 2531 and ANSI/AWWA C151/A21.51.

1. Raw Material Preparation

2. Induction Furnace Melting

3. Centrifugal Casting

4. Annealing

5. Finishing & Coating

6. Hydrostatic Testing

- Material Science: It begins with high-quality raw materials, including scrap steel, pig iron, and magnesium for the nodulizing process which transforms brittle gray iron into strong, flexible ductile iron.

- Precision Casting: In the centrifugally cast iron process, molten iron is poured into a rapidly rotating water-cooled mold. Centrifugal force distributes the metal evenly, creating a pipe with superior dimensional accuracy and material integrity.

- Heat Treatment (Annealing): This crucial step relieves internal stresses from the casting process and optimizes the metal's mechanical properties, enhancing its ductility and impact resistance.

- Finishing and Protection: Pipes undergo zinc coating and bitumen finishing externally for corrosion protection. Internally, a cement mortar lining is applied (per AWWA C104) to prevent tuberculation and maintain water quality. This makes them ideal as both water mains and as a durable cast iron conduit.

- Rigorous Testing: Every single pipe is subjected to hydrostatic pressure testing far exceeding its designed working pressure. Other tests include dimensional checks, Brinell hardness tests, and tensile strength tests to ensure compliance with international standards.

Technical Specifications and Performance Metrics

When specifying a cast iron water main pipe, engineers rely on a set of standardized technical parameters. These specifications ensure that the selected pipe can withstand the operational stresses of a modern water system. Ductile Iron Pipe is typically classified by its Pressure Class or Thickness Class (e.g., K-Class).

Below is a typical specification table for Ductile Iron Pipe (Class K9), a common standard for municipal water applications. Understanding these parameters is key for anyone looking to buy cast iron pipe for a specific project.

| Nominal Diameter (DN) mm | Outside Diameter (OD) mm | Nominal Wall Thickness (mm) | Working Pressure (bar) | Standard Compliance |

|---|---|---|---|---|

| 100 | 118 | 6.0 | 64 | ISO 2531 / EN 545 |

| 200 | 222 | 6.3 | 56 | ISO 2531 / EN 545 |

| 300 | 326 | 7.2 | 50 | ISO 2531 / EN 545 |

| 400 | 429 | 8.1 | 45 | ISO 2531 / EN 545 |

| 500 | 532 | 9.0 | 42 | ISO 2531 / EN 545 |

| 600 | 635 | 9.9 | 38 | ISO 2531 / EN 545 |

Note: Data is illustrative for K9 class. Always consult manufacturer-specific data sheets for project design.

Data-Driven Advantages: Visualizing Performance

The superiority of modern casting technology isn't just a claim; it's backed by data. While we specialize in a wide array of precision casting products, the underlying principles of material integrity and performance are universal. The charts below illustrate key performance indicators relevant to high-quality cast products, from cast drain pipe to complex industrial components.

Material Composition of Modern Ductile Iron

The unique properties of ductile iron come from its specific elemental composition, which is carefully controlled during manufacturing.

Key Technical Advantages of Ductile Iron Piping

The decision to use cast ductile iron pipe for water infrastructure is based on a compelling set of technical and economic advantages over other materials like PVC, steel, or concrete.

- Unmatched Strength and Durability: Ductile iron possesses high tensile strength (minimum 42,000 psi) and flexibility. It can withstand significant internal pressure, pressure surges (water hammer), deep burial depths, and heavy surface traffic without fracturing.

- Inherent Corrosion Resistance: The graphitic and siliceous nature of iron forms a stable oxide layer upon exposure to the environment, providing a natural barrier to corrosion. This is further enhanced by modern zinc and epoxy coatings, making it suitable even for aggressive soil conditions. This also applies to other uses like cast iron heating pipes.

- Exceptional Lifespan: With a documented service life exceeding 100 years in many locations, ductile iron pipes represent a long-term investment, offering the lowest life-cycle cost of any common pipe material.

- Superior Joint Integrity: Push-on and mechanical joints (like the Tyton Joint®) are robust yet flexible, allowing for deflection during installation and accommodating ground settlement without leaking, a critical factor in seismically active areas.

- Tapping and Installation Ease: Ductile iron pipes can be easily and directly tapped for service connections without the need for expensive and failure-prone saddles, simplifying installation and maintenance.

Corrosion Resistance Comparison (Normalized Rate)

This chart illustrates the superior long-term performance of coated ductile iron compared to unprotected steel in typical soil conditions.

Sourcing and Partnership: Beyond the Product

Choosing a supplier for a critical infrastructure component like a cast iron water main pipe involves more than just comparing prices. It's about securing a partnership with a manufacturer that demonstrates profound expertise, certified quality, and reliable support. These are principles we embed in every product we create.

Our Expertise in Advanced Casting Technology

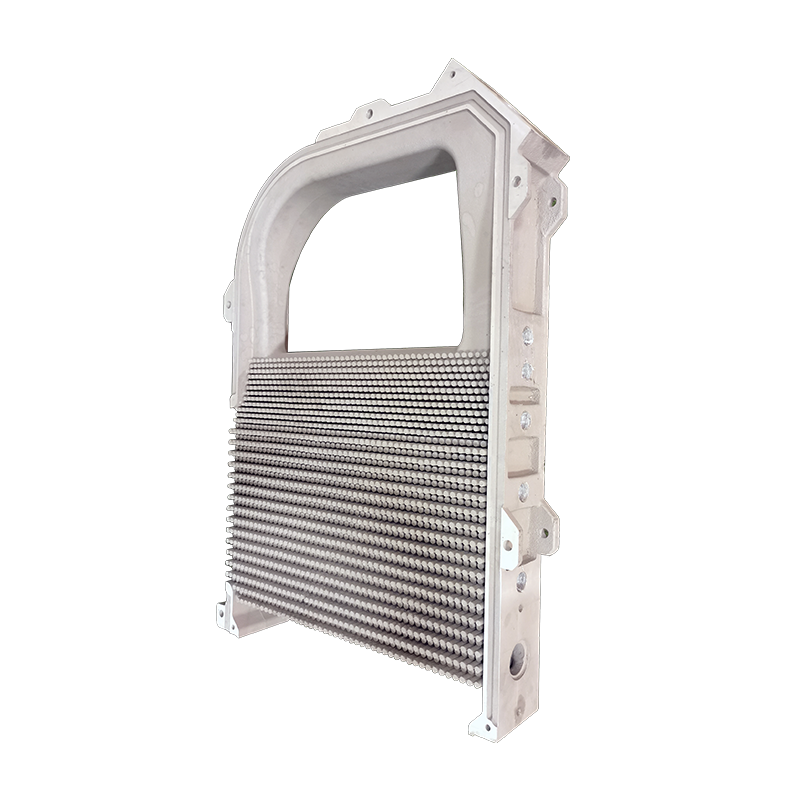

Our mastery in metallurgical science and precision casting isn't confined to pipes. It's the core competency that drives the innovation behind all our high-performance products. A prime example is our Cast Aluminum-Silicon Alloy Radiator/Exchanger. This product, designed for natural gas-fired boilers, leverages sophisticated casting techniques to achieve complex geometries, superior heat transfer, and exceptional corrosion resistance—the same foundational principles of quality and durability that define a superior centrifugally cast iron pipe.

Whether it's an industrial heat exchanger or a municipal water main, our commitment to ISO 9001 certified processes, rigorous material testing, and advanced manufacturing ensures every component delivers unmatched performance and longevity.

Manufacturer Comparison: What to Look For

| Feature | Premium, Certified Manufacturer | Standard Supplier |

|---|---|---|

| Certifications | ISO 9001, ANSI/AWWA, NSF/ANSI 61 | May have basic or no certifications |

| Material Traceability | Full traceability from raw material to finished pipe | Limited or no traceability |

| Quality Control | In-house hydrostatic, tensile, and chemical analysis per pipe batch | Random or external spot checks |

| Technical Support | Dedicated engineering support for design and installation | Basic sales support |

| Warranty & Lifespan | Comprehensive warranty, proven 100+ year service life | Limited warranty, unproven longevity |

Customization and Real-World Application Case Studies

While standard sizes cover most needs, many projects require specialized solutions. We offer customization options including non-standard lengths, special coatings for highly corrosive environments (e.g., polyurethane), and a wide array of fittings. This flexibility extends to various applications, from potable water to specialized uses like cast iron drain pipes for sale in large-scale commercial developments.

Case Study: Metropolis Water Grid Modernization

Challenge: The City of Metropolis was facing frequent water main breaks in its aging, 80-year-old gray cast iron network, leading to service disruptions and significant water loss.

Solution: A multi-year replacement program was initiated using modern cast ductile iron pipe. The choice was based on its proven longevity, its ability to withstand heavy urban traffic loads, and the ease of installation with flexible push-on joints, which minimized traffic disruption.

Outcome: After the first phase of replacement, the city reported an 85% reduction in water main breaks in the upgraded zones. The cement mortar lining maintained water quality and hydraulic efficiency, and the project was completed ahead of schedule due to the streamlined installation process. This success story showcases the tangible benefits of investing in high-quality infrastructure.

Frequently Asked Questions (FAQ)

The primary difference lies in the form of graphite in the metal's microstructure. In Gray Cast Iron, graphite exists as sharp flakes, making the material brittle. In Ductile Iron, a treatment with magnesium converts the graphite into spheroidal nodules. This rounded shape eliminates stress points, making Ductile Iron significantly stronger, more flexible (ductile), and far more resistant to impact and pressure than gray iron.

The most globally recognized standards are ISO 2531 and its European equivalent EN 545. In the United States, the American Water Works Association (AWWA) standards are paramount, such as AWWA C151/A21.51 for the pipe itself, AWWA C104 for cement mortar lining, and AWWA C111 for rubber-gasket joints. Adherence to these standards ensures product quality and interoperability.

The outside diameter is a critical dimension controlled by the precision-machined internal diameter of the centrifugal casting mold. This ensures consistent ODs across production runs, which is essential for proper fitment with standardized joints and fittings. The ODs are standardized according to specifications like AWWA C151.

Absolutely. Its strength and durability make it an excellent choice for a variety of applications, including sewage and wastewater force mains, raw water intakes, industrial process piping, and as a protective cast iron conduit for other utilities. Its use as a cast drain pipe is common in large buildings and industrial settings due to its fire resistance and sound-dampening qualities.

With modern manufacturing techniques, corrosion protection systems (like zinc coatings and polyethylene sleeving in aggressive soils), and cement mortar linings, the expected service life of a ductile iron pipe is well over 100 years. This longevity is a key factor in its low overall life-cycle cost.

To properly specify the pipe, you need to define the Nominal Diameter (e.g., DN 300), the Pressure Class or Thickness Class (e.g., K9 or PC 350), the required joint type (e.g., Push-on or Mechanical Joint), and the applicable standard (e.g., ISO 2531 or AWWA C151). Contacting a reputable manufacturer with these details will ensure you receive a precise quote and the correct product.

While copper and PEX are common in modern residential heating, cast iron is still widely used in large-scale hydronic heating systems, such as in industrial facilities, large commercial buildings, and district heating networks. Its strength, pressure tolerance, and excellent heat retention make it a very effective and durable choice for these demanding applications.

Our Commitment to Trust, Quality, and Service

Trust is the foundation of any critical infrastructure project. We build that trust by embedding quality into every step of our process and backing it with unwavering customer support. Our manufacturing facilities are ISO 9001:2015 certified, and our products meet or exceed the highest international standards.

- Guaranteed Quality: Every cast iron water main pipe we produce undergoes a battery of tests before it leaves our facility. We provide full material test reports (MTRs) and certificates of compliance with every shipment.

- Reliable Delivery: We understand that project timelines are critical. Our logistics team works diligently to ensure on-time delivery to your job site, anywhere in the world. Typical lead times range from 4 to 8 weeks, depending on order size and customization.

- Comprehensive Warranty: We stand behind our products with a comprehensive manufacturer's warranty, giving you peace of mind and protecting your investment.

- Expert Support: Our team of engineers and product specialists is available to assist you with everything from initial design and product selection to installation guidance and troubleshooting.

Authoritative References & Further Reading

This content is compiled based on extensive industry knowledge and authoritative sources. For deeper technical exploration, we recommend the following resources:

1. Ductile Iron Pipe Research Association (DIPRA): A leading authority on ductile iron pipe, providing extensive research, technical papers, and design guides. Visit DIPRA

2. American Water Works Association (AWWA): The primary organization for setting standards in the North American water industry. The AWWA C151/A21.51 standard is a benchmark for pipe manufacturing. Visit AWWA

3. Journal of Pipeline Systems Engineering and Practice: An academic journal from the American Society of Civil Engineers (ASCE) that often publishes peer-reviewed research on the performance and longevity of different pipe materials. Explore the Journal

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025