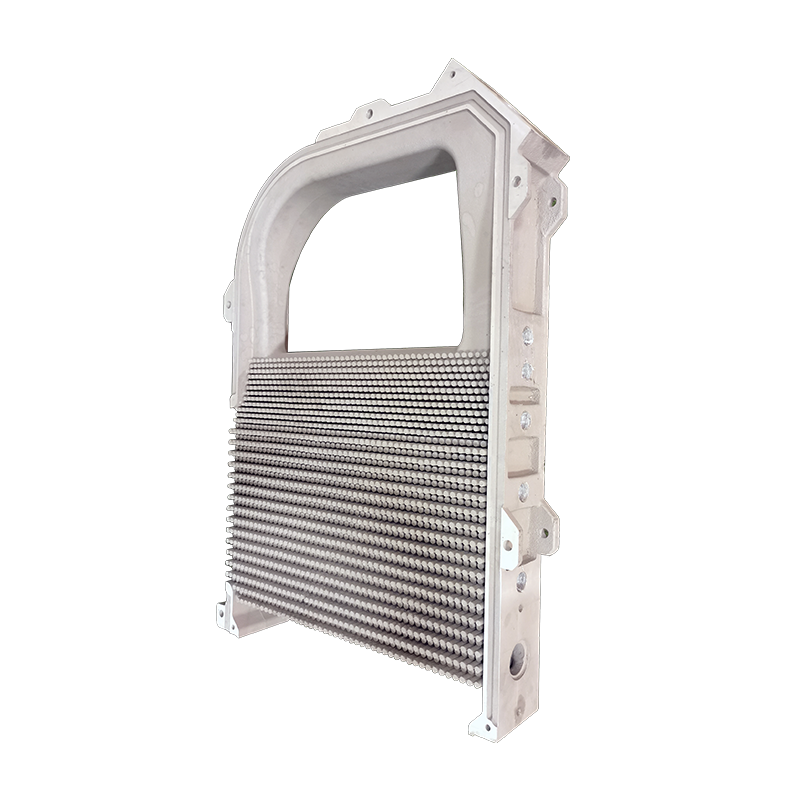

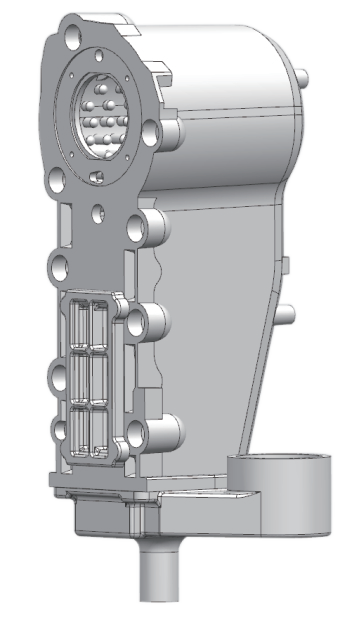

Cast Aluminum-Silicon Alloy Radiator/ Exchanger for Natural Gas Fired Boiler

Material Introduction

High-silicon aluminum alloy is a binary alloy composed of silicon and aluminum, and is a metal-based thermal management material. The high-silicon aluminum alloy material can maintain the excellent properties of silicon and aluminum, does not pollute the environment, and is harmless to the human body. The density of high-silicon aluminum alloy is between 2.4~2.7 g/cm³, and the coefficient of thermal expansion (CTE) is between 7-20ppm/℃. Increasing the silicon content can significantly reduce the density and thermal expansion coefficient of the alloy material. At the same time, high-silicon aluminum alloy also has good thermal conductivity, high specific stiffness and rigidity, good plating performance with gold, silver, copper, and nickel, weldable with the substrate, and easy precision machining. It is an electronic packaging material with broad application prospects.

The manufacturing methods of high-silicon aluminum alloy composite materials mainly include the following: 1) smelting and casting; 2) infiltration method; 3) powder metallurgy; 4) vacuum hot pressing method; 5) rapid cooling/spray deposition method.

Production Process

1) Melting and casting method

The equipment for smelting and casting method is simple , low cost, and can realize large-scale industrial production, and it is the most extensive preparation method for alloy materials.

2) Impregnation method

The impregnation method consist of two methods: pressure infiltration method and pressureless infiltration method. The pressure infiltration method uses mechanical pressure or compressed gas pressure to make the base metal melt immerse into the reinforcement gap.

3) Powder metallurgy

Powder metallurgy is to disperse a certain proportion of aluminum powder, silicon powder and binder uniformly, mix and shape the powders by dry pressing, injection and other methods, and finally sinter in a protective atmosphere to form a denser material.

4) Vacuum hot pressing method

The vacuum hot pressing method refers to a sintering process in which pressure forming and pressure sintering are carried out at the same time. Its advantages are: ①The powder is easy to plastically flow and densify; ②The sintering temperature and sintering time are short; ③The density is high. The general process is: under vacuum conditions, the powder is placed in the mold cavity, the powder is heated while being pressurized, and a compact and uniform material is formed after a short time of pressurization.

5) Rapid cooling/spray deposition

Rapid cooling/spray deposition technology is a rapid solidification technology. It has the following advantages: 1) no macro-segregation; 2) fine and uniform equiaxed crystal microstructure; 3) fine primary precipitation phase; 4) low oxygen content; 5) improved thermal processing performance.

Classification

(1) Hypoeutectic silicon aluminum alloy contains 9%-12% silicon.

(2) Eutectic silicon aluminum alloy contains 11% to 13% silicon.

(3) The silicon content of hypereutectic aluminum alloy is above 12%, mainly in the range of 15% to 20%.

(4) Those with a silicon content of 22% or more are called high-silicon aluminum alloys, of which 25%-70% are the main ones, and the highest silicon content in the world can reach 80%.

Application

1) High-power integrated circuit packaging: high-silicon aluminum alloy provides effective heat dissipation;

2) Carrier: It can be used as a local heat sink to make the components more closely arranged;

3) Optical frame: high silicon aluminum alloy provides low thermal expansion coefficient, high rigidity and workability;

4) Heat sink: High silicon aluminum alloy provides effective heat dissipation and structural support.

5) Auto parts: High-silicon aluminum alloy material (silicon content 20%-35%) has excellent tribological properties, and can be used as an advanced lightweight wear-resistant material for use in various transportation tools, various power machinery, and machine tools. , Special fasteners and tools have been widely used.

High-silicon aluminum alloy has a series of advantages such as small specific gravity, light weight, good thermal conductivity, low thermal expansion coefficient, volume stability, good wear resistance, and good corrosion resistance, and is widely used as cylinder liners, pistons, and rotors of automobile engines. , Brake discs and other materials.