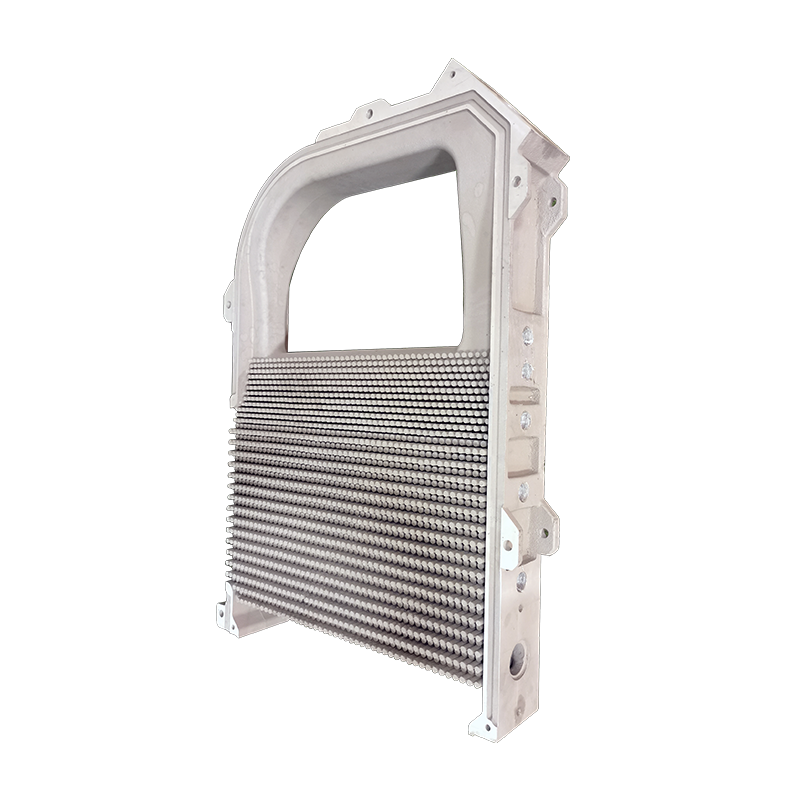

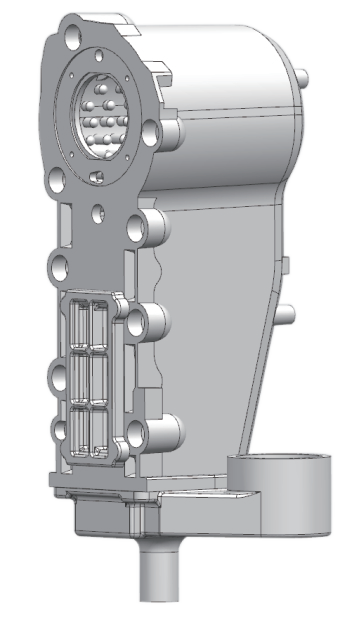

Cam khwb cia Aluminium-Silicon Alloy Radiator / Exchanger rau Natural Gas Fired Boiler

Khoom Taw Qhia

High-silicon aluminium alloy yog binary alloy tsim ntawm silicon thiab txhuas, thiab yog cov khoom siv thermal tswj cov hlau. Cov khoom siv high-silicon aluminium alloy tuaj yeem tswj tau cov khoom zoo ntawm silicon thiab txhuas, tsis ua paug rau ib puag ncig, thiab tsis muaj teeb meem rau tib neeg lub cev. Qhov ceev ntawm high-silicon aluminium alloy yog nruab nrab ntawm 2.4 ~ 2.7 g / cm³, thiab cov coefficient ntawm thermal expansion (CTE) yog nyob nruab nrab ntawm 7-20ppm / ℃. Ua kom cov ntsiab lus silicon tuaj yeem txo qhov ceev thiab thermal expansion coefficient ntawm cov khoom siv hlau. Nyob rau tib lub sijhawm, high-silicon aluminium alloy kuj muaj cov thermal conductivity zoo, siab tshwj xeeb nruj thiab rigidity, zoo plating kev ua tau zoo nrog kub, nyiaj, tooj liab, thiab npib tsib xee, weldable nrog substrate, thiab yooj yim precision machining. Nws yog cov khoom ntim khoom siv hluav taws xob nrog rau kev thov dav dav.

Kev tsim cov txheej txheem ntawm high-silicon aluminium alloy cov ntaub ntawv feem ntau suav nrog cov hauv qab no: 1) smelting thiab casting; 2) txoj kev infiltration; 3) hmoov metallurgy; 4) lub tshuab nqus tsev kub nias txoj kev; 5) ceev cua txias / tshuaj tsuag deposition txoj kev.

Txheej txheem ntau lawm

1) Melting thiab casting txoj kev

Cov cuab yeej siv rau smelting thiab casting txoj kev yog yooj yim, tsis tshua muaj nqi, thiab muaj peev xwm paub loj-scale industrial ntau lawm, thiab nws yog ib tug ntau yam kev npaj rau cov ntaub ntawv alloy.

2) Impregnation txoj kev

Txoj kev impregnation muaj ob txoj hauv kev: txoj hauv kev siab infiltration thiab pressureless infiltration method. Lub siab infiltration txoj kev siv cov neeg kho tshuab siab los yog compressed gas siab ua rau lub hauv paus hlau yaj rau hauv qhov sib txawv ntawm qhov reinforcement.

3) hmoov metallurgy

Hmoov metallurgy yog disperse ib feem ntawm txhuas hmoov, silicon hmoov thiab binder uniformly, sib tov thiab puab cov hmoov los ntawm qhuav nias, txhaj tshuaj thiab lwm txoj kev, thiab thaum kawg sinter nyob rau hauv ib tug tiv thaiv cua los tsim ib tug denser khoom.

4) Vacuum kub nias txoj kev

Lub tshuab nqus tsev kub nias txoj kev hais txog cov txheej txheem sintering uas lub siab tsim thiab siab sintering tau ua tib lub sijhawm. Nws qhov zoo yog: ① Cov hmoov yog yooj yim rau plastically ntws thiab densify; ② Lub sintering kub thiab sintering lub sij hawm luv luv; ③ Qhov ceev yog siab. Cov txheej txheem dav dav yog: nyob rau hauv lub tshuab nqus tsev, cov hmoov yog muab tso rau hauv pwm kab noj hniav, cov hmoov yog rhuab thaum lub sij hawm pressurized, thiab ib tug compact thiab uniform khoom yog tsim tom qab ib tug luv luv lub sij hawm ntawm pressurization.

5) Kev ua kom txias / tshuaj tsuag sai sai

Kev ua kom txias / tshuaj tsuag sai sai yog lub tshuab ua kom khov sai. Nws muaj qhov zoo hauv qab no: 1) tsis muaj kev sib cais; 2) zoo thiab niaj hnub equiaxed crystal microstructure; 3) zoo thawj theem nag lossis daus; 4) cov pa oxygen tsawg; 5) txhim kho thermal ua haujlwm.

Kev faib tawm

(1) Hypoeuectic silicon aluminium alloy muaj 9% -12% silicon.

(2) Eutectic silicon aluminium alloy muaj 11% mus rau 13% silicon.

(3) Cov ntsiab lus silicon ntawm hypereutectic aluminium alloy yog siab dua 12%, feem ntau yog nyob rau hauv thaj tsam ntawm 15% mus rau 20%.

(4) Cov uas muaj cov ntsiab lus silicon ntawm 22% lossis ntau dua yog hu ua high-silicon aluminium alloys, ntawm 25% -70% yog cov tseem ceeb, thiab cov ntsiab lus silicon siab tshaj hauv ntiaj teb tuaj yeem ncav cuag 80%.

Daim ntawv thov

1) High-power integrated circuit ntim: high-silicon aluminium alloy muab cov cua sov kom zoo;

2) Carrier: Nws tuaj yeem siv los ua lub dab dej kub hauv zos los ua kom cov khoom sib txuas ntau dua;

3) Optical thav duab: siab silicon aluminium alloy muab qis thermal expansion coefficient, siab rigidity thiab workability;

4) Thaum tshav kub kub dab dej: High silicon aluminium alloy muab cov cua sov dissipation zoo thiab kev txhawb nqa.

5) Nws pib qhov chaw: High-silicon aluminium alloy cov khoom (silicon cov ntsiab lus 20% -35%) muaj cov khoom zoo heev tribological, thiab tuaj yeem siv los ua cov khoom siv hnyav hnyav hnyav rau siv ntau yam khoom siv thauj mus los, ntau lub tshuab fais fab, thiab tshuab cuab yeej. , Tshwj xeeb fasteners thiab cov cuab yeej siv tau dav siv.

High-silicon aluminium alloy muaj cov txiaj ntsig zoo xws li lub ntiajteb txawj nqus me me, lub teeb yuag, zoo thermal conductivity, tsis tshua muaj thermal expansion coefficient, ntim stability, zoo hnav tsis kam, thiab zoo corrosion kuj, thiab yog dav siv los ua lub tog raj kheej liner, pistons, thiab rotors ntawm tsheb cav. , Nres discs thiab lwm yam khoom siv.