Ponyani Aluminiyamu-Silicon Aloyi Radiator/ Kusinthana kwa Boiler Yachilengedwe Yowotchedwa ndi Gasi

Mau Oyamba a Nkhani

High-silicon aluminium alloy ndi alloy binary wopangidwa ndi silikoni ndi aluminiyamu, ndipo ndizitsulo zopangira matenthedwe zopangira matenthedwe. Zida za aluminiyamu zapamwamba za silicon zimatha kusunga zinthu zabwino kwambiri za silicon ndi aluminiyamu, siziipitsa chilengedwe, ndipo sizivulaza thupi la munthu. Kachulukidwe ka aloyi wa aluminiyamu wapamwamba kwambiri wa silicon ndi pakati pa 2.4 ~ 2.7 g/cm³, ndipo kuchuluka kwa kukulitsa kwamafuta (CTE) kuli pakati pa 7-20ppm/℃. Kuchulukitsa za silicon kumatha kuchepetsa kwambiri kachulukidwe ndi kukulitsa kutentha kwazinthu za alloy. Pa nthawi yomweyo, mkulu-silicon zotayidwa aloyi amakhalanso ndi matenthedwe matenthedwe, mkulu enieni kuuma ndi kuuma, bwino plating ntchito ndi golide, siliva, mkuwa, ndi faifi tambala, weldable ndi gawo lapansi, ndi mosavuta mwatsatanetsatane Machining. Ndi chipangizo chamagetsi chamagetsi chomwe chili ndi chiyembekezo chogwiritsa ntchito.

Njira zopangira zida zapamwamba za silicon aluminium alloy composite makamaka zimaphatikizapo izi: 1) kusungunula ndi kuponyera; 2) njira yolowera; 3) ufa zitsulo; 4) vakuyumu otentha kukanikiza njira; 5) kuzizira kofulumira/kupopera mbewu mankhwalawa.

Njira Yopanga

1) Njira yosungunula ndi kuponyera

Zida zopangira smelting ndi kuponyera ndizosavuta, zotsika mtengo, ndipo zimatha kuzindikira kupanga kwakukulu kwamafakitale, ndipo ndiyo njira yayikulu kwambiri yokonzekera zida za alloy.

2) Njira ya Impregnation

Njira yopangira impregnation imakhala ndi njira ziwiri: njira yolowera kukakamiza komanso njira yolowera mosavutikira. Njira yolowera kukakamiza imagwiritsa ntchito kukakamiza kwamakina kapena kupanikizika kwa gasi kuti zitsulo zoyambira zisungunuke zilowe mumpata wolimbikitsira.

3) Ufa zitsulo

Ufa wazitsulo ndikumwaza gawo lina la ufa wa aluminiyamu, ufa wa silicon ndi binder mofanana, kusakaniza ndi kuumba ufawo mwa kukanikiza kowuma, jekeseni ndi njira zina, ndipo pamapeto pake sinter mumlengalenga wotetezera kuti mupange chinthu cholimba.

4) Vuta njira yotentha yotentha

The vacuum otentha kukanikiza njira amatanthauza njira sintering momwe kukakamiza kupanga ndi pressure sintering kumachitika nthawi imodzi. Ubwino wake ndi: ①Ufawu ndi wosavuta kuyenda komanso kuchulukitsa; ②Kutentha kwa sintering ndi nthawi ya sintering ndi yaifupi; ③Kachulukidwe ndi kwakukulu. Njira yonseyi ndi: pansi pazitsulo zowonongeka, ufa umayikidwa mu nkhungu, ufa umatenthedwa pamene ukukakamizidwa, ndipo chinthu chophatikizika ndi yunifolomu chimapangidwa pakapita nthawi yochepa.

5) Kuzizira kofulumira/kupopera mankhwala

Ukadaulo wozizira mwachangu/utsi wotsikirapo ndiukadaulo wolimbitsa mwachangu. Ili ndi zotsatirazi: 1) palibe tsankho lalikulu; 2) chabwino ndi yunifolomu equiaxed galasi microstructure; 3) gawo labwino kwambiri lamvula; 4) otsika mpweya wokhutira; 5) kuwongolera magwiridwe antchito amafuta.

Gulu

(1) Hypoeutectic silicon aluminium alloy ili ndi 9% -12% ya silicon.

(2) Eutectic silicon aluminium alloy ili ndi 11% mpaka 13% ya silikoni.

(3) Zomwe zili mu silicon za hypereutectic aluminium alloy ndi pamwamba pa 12%, makamaka mu 15% mpaka 20%.

(4) Amene ali ndi silicon okhutira 22% kapena kuposa amatchedwa mkulu-silicon zotayidwa aloyi, amene 25% -70% ndi waukulu, ndipo apamwamba silikoni zili padziko lonse akhoza kufika 80%.

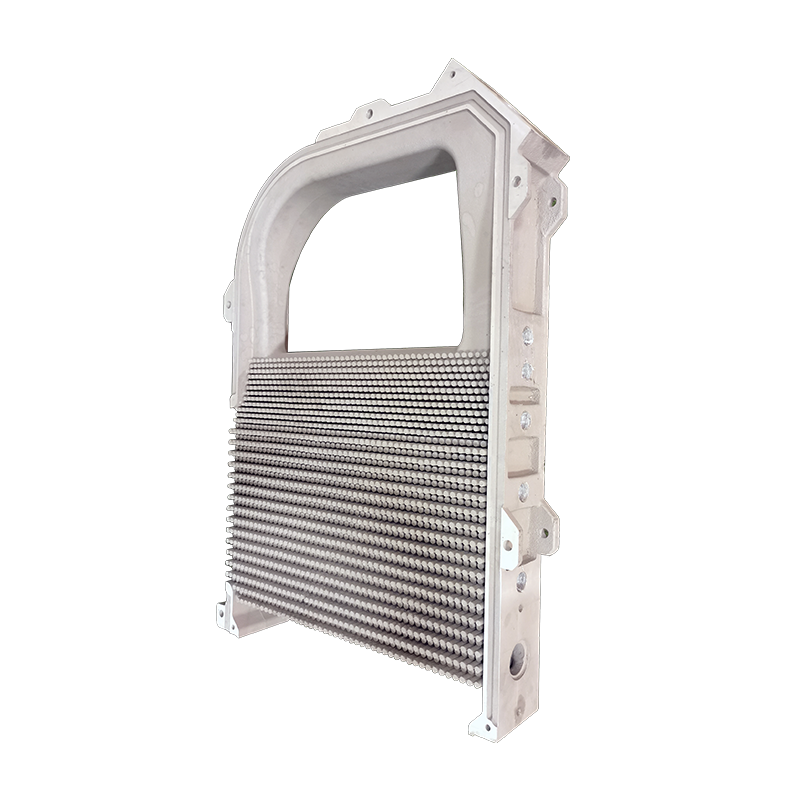

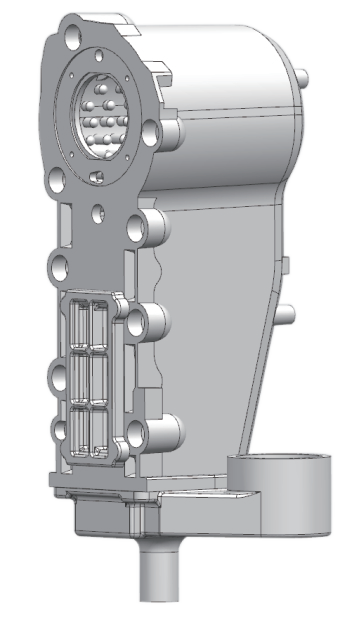

Kugwiritsa ntchito

1) Kuyika kwapang'onopang'ono kwapang'onopang'ono: zitsulo zotayidwa zapamwamba za silicon zimapereka kutentha kwabwino;

2) Chonyamulira: Ikhoza kugwiritsidwa ntchito ngati kutentha kwapafupi kuti zigawozo zikhale zogwirizana kwambiri;

3) Kuwala chimango: mkulu pakachitsulo zotayidwa aloyi amapereka otsika matenthedwe kukulitsa coefficient, mkulu olimba ndi workability;

4) Kutentha kwamadzi: High silicon aluminiyamu alloy imapereka kutentha kwabwino komanso chithandizo chamapangidwe.

5) Zigawo zamagalimoto: Zida za aluminiyamu zapamwamba za silicon (20% -35%) zili ndi zinthu zabwino kwambiri za tribological, ndipo zitha kugwiritsidwa ntchito ngati zida zapamwamba zopepuka zosagwira ntchito pazida zosiyanasiyana zoyendera, makina osiyanasiyana amagetsi, ndi makina. zida. , Zomangira zapadera ndi zida zakhala zikugwiritsidwa ntchito kwambiri.

Aluminiyamu ya aluminiyamu yapamwamba ya silicon ili ndi ubwino wambiri monga mphamvu yokoka yaing'ono, kulemera kwake, kutsekemera kwabwino kwa kutentha, kutsika kwa kutentha kwapakati, kukhazikika kwa voliyumu, kukana kuvala bwino, komanso kukana kwa dzimbiri, ndipo amagwiritsidwa ntchito kwambiri ngati ma cylinder liners, pistoni, ndi ma rotor a injini zamagalimoto. , Zimbale ananyema ndi zipangizo zina.