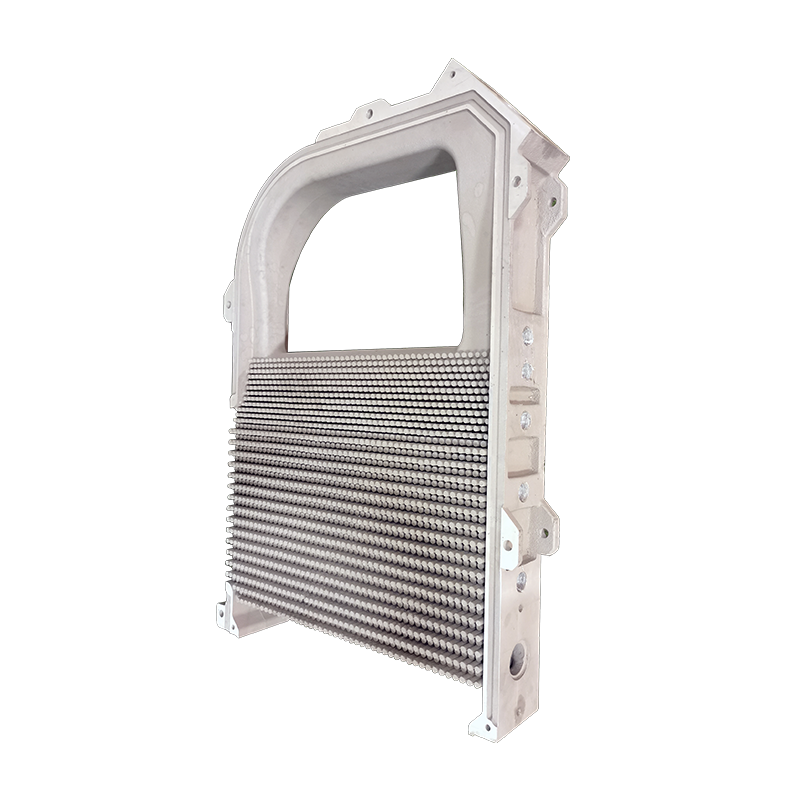

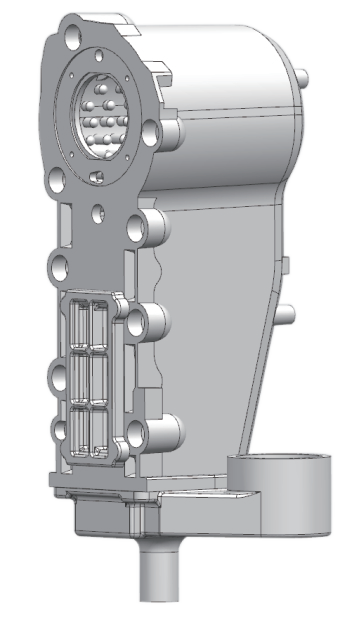

Ihe nkedo Aluminom-Silicon Alloy Radiator/ Onye na-agbanwe maka ọkụ ọkụ ọkụ ọkụ

Okwu Mmalite ihe

Alloy silicon aluminum alloy bụ ọnụọgụ ọnụọgụ abụọ mejupụtara silicon na aluminom, ma bụrụ ihe njikwa ọkụ sitere na ọla. Ngwongwo aluminom nke silicon dị elu nwere ike idowe ihe ndị dị mma nke silicon na aluminom, anaghị emetọ gburugburu ebe obibi, ọ dịghịkwa emerụ ahụ mmadụ. The njupụta nke elu-silicon aluminum alloy bụ n'etiti 2.4 ~ 2.7 g / cm³, na ọnụọgụ nke thermal mgbasa (CTE) bụ n'etiti 7-20ppm / ℃. Ịba ụba ọdịnaya silicon nwere ike ibelata njupụta na mkpokọta okpomọkụ nke ihe alloy. N'otu oge ahụ, silicon aluminum alloy na-enwekwa ezigbo conductivity thermal, elu kpọmkwem isi ike na isi ike, ezigbo plating arụmọrụ na ọla edo, ọlaọcha, ọla kọpa, na nickel, weldable na mkpụrụ, na mfe nkenke machining. Ọ bụ ihe nkwakọ ngwaahịa eletrọnịkị nwere atụmanya ngwa sara mbara.

Ụzọ mmepụta nke nnukwu silicon aluminum alloy ihe mejupụtara na-agụnye ihe ndị a: 1) ịgbaze na nkedo; 2) usoro infiltration; 3) ntụ ntụ metallurgy; 4) usoro ikpo ọkụ ọkụ; 5) usoro nkwụnye oyi / ịgbasa ngwa ngwa.

Usoro mmepụta

1) Usoro ịgbaze na nkedo

Ngwá ọrụ maka ịgbaze na usoro nkedo dị mfe, ọnụ ala dị ala, ma nwee ike ịghọta nnukwu mmepụta ụlọ ọrụ mmepụta ihe, ọ bụkwa usoro nkwadebe kachasị maka ihe alloy.

2) Usoro impregnation

Usoro impregnation nwere ụzọ abụọ: usoro ntinye nrụgide na usoro ntinye enweghị nrụgide. Usoro ntinye nrụgide na-eji nrụgide igwe ma ọ bụ nrụgide gas abịakọrọ iji mee ka metal isi gbazee na-emikpu n'ime oghere nkwado ahụ.

3) metallurgy ntụ ntụ

Ntụ ntụ metallurgy bụ achụsasịa ụfọdụ nkezi nke aluminum ntụ ntụ, silicon ntụ ntụ na ihe nkedo uniformly, mix na ịkpụzi powders site akọrọ ịpị, injection na ụzọ ndị ọzọ, na n'ikpeazụ sinter na a nchebe ikuku na-etolite a denser ihe.

4) Vacuum hot pressing method

Usoro ịpị ọkụ na-ekpo ọkụ na-ezo aka na usoro nkwụsịtụ nke a na-eme ka nrụgide na-akpụ na nrụgide nrụgide n'otu oge. Uru ya bụ: ①The ntụ ntụ dị mfe plastically eruba na densify; ②Okpomọkụ na-ekpo ọkụ na oge nkwụsịtụ dị mkpụmkpụ; ③Njupụta dị elu. Usoro n'ozuzu bụ: n'okpuru ọnọdụ agụụ, a na-etinye ntụ ntụ n'ime oghere ebu, ntụ ntụ na-ekpo ọkụ mgbe a na-agbanye ya, a na-emepụta ihe na-emepụta ihe na ihe eji eme ihe mgbe obere oge nke nrụgide gasịrị.

5) Ntinye ngwa ngwa jụrụ oyi / ịgbasa

Nkà na ụzụ nkwụnye oyi na-atụ ngwa ngwa / ịgbasa bụ nkà na ụzụ siri ike ngwa ngwa. Ọ nwere uru ndị a: 1) enweghị oke-iche; 2) mma na edo equiaxed crystal microstructure; 3) ezigbo mmiri ozuzo mbụ; 4) obere ikuku oxygen; 5) arụ ọrụ nhazi okpomọkụ ka mma.

Nhazi

(1) Hypoeutectic silicon aluminum alloy nwere 9% -12% silicon.

(2) Eutectic silicon aluminum alloy nwere 11% ruo 13% silicon.

(3) Ọdịnaya silicon nke hypereutectic aluminum alloy dị n'elu 12%, tumadi na nso nke 15% ka 20%.

(4) Ndị nwere ọdịnaya silicon nke 22% ma ọ bụ karịa ka a na-akpọ akwa silicon aluminum alloys, nke 25% -70% bụ ndị bụ isi, na ọdịnaya silicon kachasị elu n'ụwa nwere ike iru 80%.

Ngwa

1) Ngwunye sekit agbakwunyere ike dị elu: nnukwu silicon aluminum alloy na-enye nkwụsị ọkụ dị irè;

2) Onye na-ebu: Enwere ike iji ya dị ka ebe a na-ekpo ọkụ na-ekpo ọkụ na-eme ka ihe ndị ahụ na-edozi ya;

3) Igwe anya anya: elu silicon aluminum alloy na-enye ọnụọgụ mgbasawanye ọkụ dị ala, nnukwu siri ike na arụ ọrụ;

4) Igwe ọkụ ọkụ: Igwe aluminom silicon silicon dị elu na-enye nkwụsị ọkụ dị irè na nkwado nhazi.

5) Akụkụ akpaaka: ihe aluminom alloy silicon dị elu (ọdịnaya silicon 20% -35%) nwere akụrụngwa tribological magburu onwe ya, enwere ike iji ya dị ka ihe na-egbochi ịdị arọ dị arọ maka iji ya na ngwa ụgbọ njem dị iche iche, igwe ike dị iche iche, na igwe. ngwá ọrụ. , A na-eji ngwa ngwa na ngwa ngwa pụrụ iche mee ihe.

Alloy silicon silicon alloy nwere usoro uru dị ka obere obere ike ndọda, ịdị arọ dị arọ, ezigbo ọkụ eletrik, ọnụọgụ mgbasawanye dị ala, nkwụsi ike olu, nkwụsi ike dị mma na nguzogide corrosion dị mma, a na-ejikwa ya dị ka cylinder liners, pistons. na rotors nke ụgbọ ala. , diski breeki na ihe ndị ọzọ.