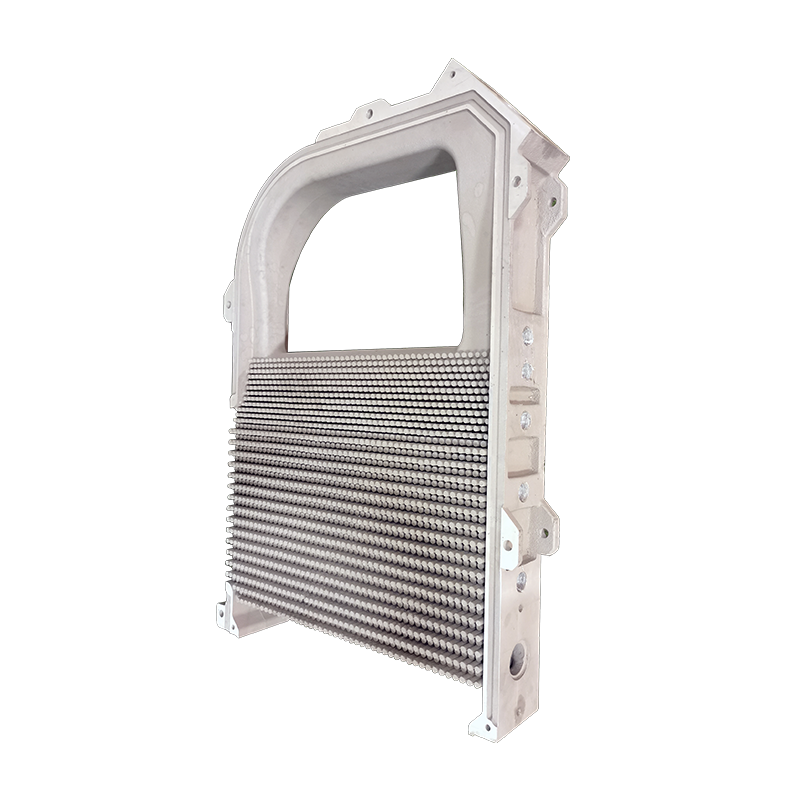

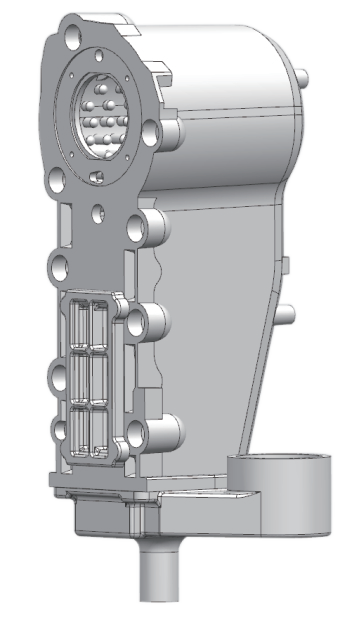

Kanda Aluminium-Silicon Alloy Radiator/ Exchanger yeGasi Rakasvirwa Boiler

Material Sumo

High-silicon aluminium alloy ibhinari alloy inoumbwa nesilicon nealuminium, uye isimbi-based thermal management material. Iyo yakakwirira-silicon aluminium alloy zvinhu inogona kuchengetedza yakanakisa zvimiro zvesilicon nealuminium, haisvibise nharaunda, uye haina kukuvadza kumuviri wemunhu. Kuwanda kwepamusoro-silicon aruminiyamu alloy iri pakati pe2.4 ~ 2.7 g/cm³, uye coefficient yekuwedzera kwekupisa (CTE) iri pakati pe7-20ppm/℃. Kuwedzera iyo silicon yemukati inogona kuderedza zvakanyanya density uye kupisa kwekuwedzera coefficient yealloy zvinhu. Panguva imwecheteyo, yakakwira-silicon aruminiyamu alloy zvakare ine yakanaka yekupisa yekupisa, yakanyanya kuomarara uye kuomarara, yakanaka plating kuita negoridhe, sirivheri, mhangura, uye nickel, inokwenenzverwa ne substrate, uye nyore kuita machining. Iyo yemagetsi yekurongedza zvinhu ine yakakura application tarisiro.

Nzira dzekugadzira dzepamusoro-silicon aluminium alloy composite zvinhu zvinonyanya kusanganisira zvinotevera: 1) kunyunguduka nekukanda; 2) nzira yekupinza; 3) upfu metallurgy; 4) vacuum inopisa kudzvanya nzira; 5) kukurumidza kutonhora / kupfapfaidza deposition nzira.

Production Process

1) Kunyunguduka uye kukanda nzira

Midziyo yekunyungudutsa uye yekukanda nzira iri nyore, yakaderera mutengo, uye inogona kuona yakakura-yakakura kugadzirwa kwemaindasitiri, uye ndiyo yakanyanya kuwanda nzira yekugadzirira yealloy zvinhu.

2) Impregnation nzira

Iyo nzira yekupinza inosanganisira nzira mbiri: nzira yekumanikidza yekupinza uye isina kudzvanywa nzira yekupinza. Iyo yekumanikidza kupinza nzira inoshandisa mechanical kudzvanywa kana kudzvanywa gasi kumanikidza kuita kuti hwaro hwesimbi hunyunguduke kunyura mukati megeji rekusimbisa.

3) Poda metallurgy

Powder metallurgy ndeyekuparadzira chimwe chikamu chealuminium poda, silicon poda uye binder zvakafanana, kusanganisa uye kuumba hupfu nekudzvanya kwakaoma, jekiseni nedzimwe nzira, uye pakupedzisira sinter mumhepo inodzivirira kuti iite denser material.

4) Vacuum inopisa kudzvanya nzira

Iyo vacuum inopisa yekutsikirira nzira inoreva nzira yekuisa umo dhizaini inoumba uye kudzvanya sintering inoitwa panguva imwe chete. Zvakanakira zvaro ndezvi: ① Hupfu huri nyore kuyerera mupurasitiki uye kuomesa; ②The sintering tembiricha uye sintering nguva ipfupi; ③Density yakakwira. Iyo yakajairika maitiro ndeiyi: pasi pevacuum mamiriro, hupfu hunoiswa mugomba rekuumbwa, hupfu hunopisa uchiri kumanikidzwa, uye compact uye yunifomu zvinhu zvinoumbwa mushure menguva pfupi yekumanikidza.

5) Kukurumidza kutonhora / kupfapfaidza deposition

Kukurumidza kutonhora / kupfapfaidza deposition tekinoroji inokurumidza kusimbisa tekinoroji. Iine zvinotevera zvakanakira: 1) hapana macro-segregation; 2) yakanaka uye yunifomu equiaxed crystal microstructure; 3) chikamu chakanaka chekunaya kwemvura; 4) okisijeni yakaderera; 5) yakagadziridzwa thermal processing performance.

Classification

(1) Hypoeutectic silicon aruminiyamu alloy ine 9% -12% nesilicon.

(2) Eutectic silicon aruminiyamu alloy ine 11% kusvika 13% silicon.

(3) Iyo silicon yemukati ye hypereutectic aluminium alloy iri pamusoro pe12%, kunyanya muhuwandu hwe15% kusvika 20%.

(4) Avo vane silicon content ye22% kana kupfuura vanonzi high-silicon aruminiyamu alloys, iyo 25% -70% ndiyo inonyanya, uye iyo yepamusoro-silicon yehuwandu munyika inogona kusvika 80%.

Application

1) High-power integrated circuit packaging: high-silicon aruminiyamu alloy inopa hunobudirira kupisa kupisa;

2) Mutakuri: Inogona kushandiswa senzvimbo yekupisa inonyura kuita kuti zvikamu zvinyatsorongeka;

3) Optical furemu: yakakwira silicon aluminium alloy inopa yakaderera thermal yekuwedzera coefficient, yakakwirira kuomarara uye kushanda;

4) Heat sink: Yakakwira silicon aruminiyamu alloy inopa inoshanda kupisa kupisa uye kutsigirwa kwechimiro.

5) Zvikamu zvemotokari: Yakakwira-silicon aruminiyamu alloy zvinhu (silicon yemukati 20% -35%) ine yakanakisa tribological zvivakwa, uye inogona kushandiswa seyepamberi isingapfeki zvinhu zvekushandisa mumidziyo yakasiyana-siyana yekufambisa, michina yemagetsi yakasiyana, uye muchina. zvishandiso. , Special fasteners uye zvishandiso zvakashandiswa zvakanyanya.

High-silicon aruminiyamu alloy ine zvakatevedzana zvakanakira senge diki chaiyo giravhiti, huremu huremu, yakanaka yekupisa conductivity, yakaderera thermal yekuwedzera coefficient, kugadzikana kwevhoriyamu, kupfeka kwakanaka kuramba, uye yakanaka corrosion resistance, uye inoshandiswa zvakanyanya semacylinder liners, pistons, uye rotor dzeinjini dzemotokari. , Brake discs nezvimwe zvinhu.