Radiator ea Aluminium-Silicon Alloy Radiator/ Exchanger bakeng sa Boiler e Tletseng Khase ea Tlhaho

Selelekela sa Boitsebiso

High-silicon aluminium alloy ke motsoako oa binary o entsoeng ka silicon le aluminium, 'me ke thepa ea tsamaiso ea mocheso e thehiloeng ka tšepe. Thepa e phahameng ea silicon alloy alloy e ka boloka thepa e babatsehang ea silicon le aluminium, ha e silafatse tikoloho, ebile ha e kotsi 'meleng oa motho. Boima ba alloy ea aluminium e phahameng ea silicon e pakeng tsa 2.4 ~ 2.7 g/cm³, 'me coefficient ea katoloso ea mocheso (CTE) e pakeng tsa 7-20ppm/℃. Ho eketsa dikahare tsa silicon ho ka fokotsa haholo boima ba 'mele le katoloso ea mocheso oa thepa ea alloy. Ka nako e ts'oanang, alloy ea aluminium e phahameng ea silicon e boetse e na le conductivity e ntle ea mocheso, ho satalla ho khethehileng le ho tiea, ts'ebetso e ntle ea ho roala ka khauta, silevera, koporo le nickel, e chesehang ka substrate, le machining a bonolo. Ke thepa ea ho paka ea elektroniki e nang le menyetla e pharaletseng ea ts'ebeliso.

Mekhoa ea tlhahiso ea lisebelisoa tse entsoeng ka silicon e ngata ea aluminium alloy haholo-holo e kenyelletsa tse latelang: 1) ho qhibiliha le ho lahla; 2) mokhoa oa ho kenella; 3) phofo ea metallurgy; 4) vacuum chesang ho tobetsa mokhoa; 5) mokhoa oa ho pholisa ka potlako / ho fafatsa mokhoa oa ho beha.

Mokhoa oa Tlhahiso

1) Mokhoa oa ho qhibiliha le oa ho lahla

Thepa ea ho qhibiliha le mokhoa oa ho lahla o bonolo, o theko e tlaase, 'me o khona ho lemoha tlhahiso e kholo ea indasteri,' me ke mokhoa o pharaletseng ka ho fetisisa oa ho lokisetsa lisebelisoa tsa alloy.

2) Mokhoa oa ho ima

Mokhoa oa ho kenya letsoho o na le mekhoa e 'meli: mokhoa oa ho kenya khatello le mokhoa oa ho kena ka ntle ho khatello. Mokhoa oa ho kenella ka khatello o sebelisa khatello ea mochine kapa khatello ea khase e hatelitsoeng ho etsa hore tšepe e qhibilihe e qoelisoe ka har'a lekhalo la ho matlafatsa.

3) Metallurgy ea phofo

Metallurgy ea phofo ke ho qhala karolo e itseng ea phofo ea aluminium, phofo ea silicon le binder ka mokhoa o ts'oanang, ho kopanya le ho bopa li-powders ka ho hatella ka ho omella, ente le mekhoa e meng, 'me qetellong sinter sebakeng se sireletsang ho etsa thepa e teteaneng.

4) Vacuum e chesang e hatellang mokhoa

Mokhoa oa ho hatella o chesang oa vacuum o bolela mokhoa oa sintering oo ho oona ho thehoang khatello le khatello ea khatello e etsoang ka nako e le 'ngoe. Melemo ea eona ke: ① phofo e bonolo ho phalla ka polasetiki le ho teteana; ②Thempereichara ea sintering le nako ea sintering e khuts'oane; ③Tekano e holimo. Ts'ebetso e akaretsang ke: tlas'a maemo a vacuum, phofo e kenngoa ka sekoting sa hlobo, phofo e futhumetse ha e ntse e hatelloa, 'me thepa e kopanetsoeng le e ts'oanang e thehoa ka mor'a nako e khutšoanyane ea khatello.

5) Pholiso e potlakileng / ho fafatsa ho beha

Theknoloji ea ho pholile ka potlako / spray deposition ke theknoloji e potlakileng ea ho tiisa. E na le melemo e latelang: 1) ha ho na karohano e kholo; 2) e ntle le e junifomo equiaxed kristale microstructure; 3) mohato o motle oa pele oa pula; 4) oksijene e fokolang; 5) ho ntlafatsa ts'ebetso ea mocheso oa mocheso.

Karolelano

(1) Hypoeutectic silicon aluminium alloy e na le 9% -12% silicon.

(2) Eutectic silicon aluminium alloy e na le silicon ea 11% ho isa ho 13%.

(3) Likahare tsa silicon tsa hypereutectic aluminium alloy li ka holimo ho 12%, haholo-holo ho tloha ho 15% ho ea ho 20%.

(4) Ba nang le silicon content ea 22% kapa ho feta ba bitsoa high-silicon aluminium alloys, eo 25% -70% e leng eona e ka sehloohong, 'me lihlahisoa tse phahameng ka ho fetisisa tsa silicon lefatšeng li ka fihla ho 80%.

Kopo

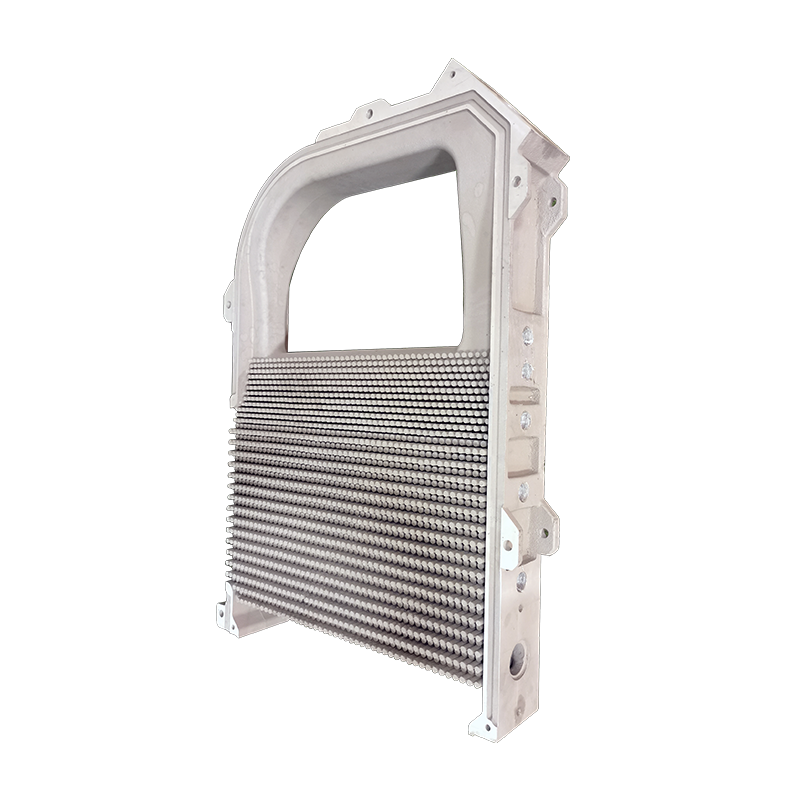

1) Sephutheloana sa potoloho se kopantsoeng ka matla a phahameng: alloy ea aluminium e phahameng ea silicon e fana ka mocheso o sebetsang hantle oa mocheso;

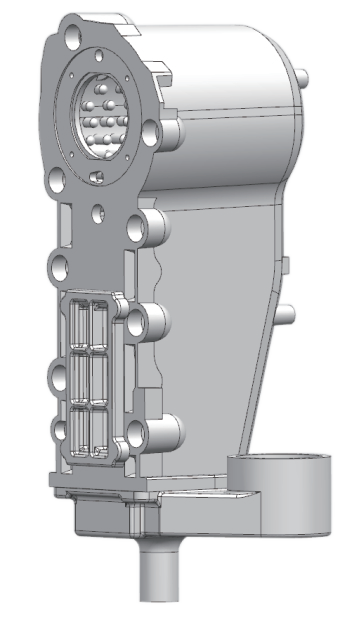

2) Carrier: E ka sebelisoa e le setsi sa mocheso sa sebakeng seo ho etsa hore likarolo li behoe haufi-ufi;

3) Foreimi ea Optical: alloy e phahameng ea silicon aluminium e fana ka coefficient e tlase ea katoloso ea mocheso, ho tiea ho hoholo le ho sebetsa;

4) Mocheso oa mocheso: Alloy ea silicon e phahameng ea aluminium e fana ka mokhoa o sebetsang oa ho senya mocheso le tšehetso ea sebopeho.

5) Likarolo tsa likoloi: Lisebelisoa tsa alloy alloy ea silicon e phahameng (liteng tsa silicon 20% -35%) li na le thepa e ntle ea tribological, 'me li ka sebelisoa e le lisebelisoa tse sa sebetseng tse bobebe ho sebelisoa lisebelisoa tse fapaneng tsa lipalangoang, metjhini e fapaneng ea matla le mochini. lisebelisoa. , Li-fasteners tse khethehileng le lisebelisoa li 'nile tsa sebelisoa haholo.

High-silicon alloy alloy e na le letoto la melemo e kang matla a khoheli a manyane, boima bo bobebe, conductivity e ntle ea mocheso, coefficient e tlase ea katoloso ea mocheso, botsitso ba molumo, khanyetso e ntle ea ho roala le ho hanyetsa kutu, 'me e sebelisoa haholo joalo ka li-cylinder liners, pistons. le li-rotor tsa enjine ea likoloi. , Li-disk tsa Brake le lisebelisoa tse ling.