ທ.ວ. . 10, 2024 19:53 Back to list

Understanding the Process of Casting Cast Iron Pipes for Effective Delivery Systems

Understanding Cast Iron Pipe Casting A Comprehensive Overview

Cast iron pipe casting has been a fundamental process in the manufacturing and construction industries for decades. Its durability, strength, and resistance to corrosion have made cast iron an ideal material for a variety of applications, particularly in plumbing and sewage systems. In this article, we will explore the intricacies of cast iron pipe casting, its manufacturing processes, advantages, and the future of this vital industrial practice.

What is Cast Iron?

Cast iron is an iron-carbon alloy that typically contains 2-4% carbon, along with varying percentages of silicon, manganese, and other elements. Its composition gives cast iron its unique properties, making it an exceptionally malleable material that can be easily cast into complex shapes. The primary forms of cast iron used in pipe manufacturing include gray iron and ductile iron, each offering distinct characteristics suitable for different applications.

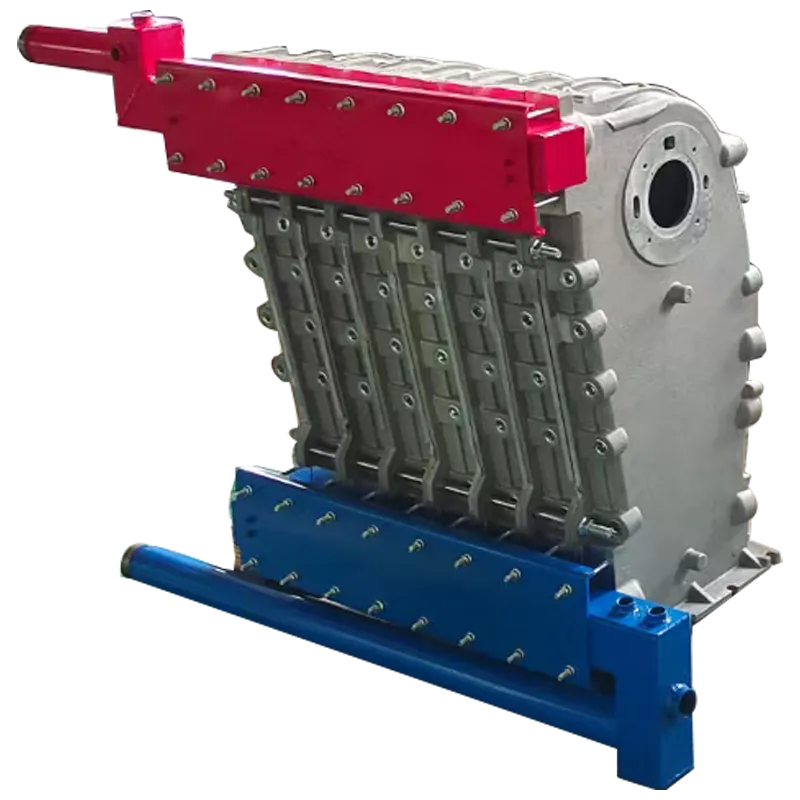

The Casting Process

The casting of iron pipes involves several key steps, beginning with the creation of molds. These molds can be made from sand, metal, or other materials and are shaped according to the specifications needed for the pipes. Once the molds are prepared, molten iron is poured into them. The temperature of the molten iron typically reaches around 1,400 to 1,600 degrees Celsius. After the iron cools and solidifies, the mold is removed, leaving behind the cast iron pipe.

A critical component of this process is ensuring that the iron is free from impurities. The quality of the final product depends heavily on the purity of the raw materials used, making it essential for manufacturers to source high-quality iron and maintain stringent quality control measures throughout the casting process.

Advantages of Cast Iron Pipes

Cast iron pipes boast numerous advantages that have contributed to their enduring popularity.

1. Durability Cast iron pipes are known for their strength and longevity. They can withstand high pressure and heavy loads, making them ideal for use in infrastructure projects such as water distribution systems and sewage lines.

cast iron pipe casting

2. Corrosion Resistance Unlike many other materials, cast iron has a natural resistance to corrosion, particularly when coated with protective layers. This resistance helps to extend the lifespan of pipes and reduces the need for frequent replacements.

3. Sound Damping Cast iron pipes have excellent sound-damping properties. This characteristic minimizes noise pollution, making them an ideal choice for urban plumbing installations where noise can be a concern.

4. Fire Resistance Cast iron is non-combustible, offering an additional layer of safety when used in building applications.

5. Environmental Impact Cast iron is fully recyclable. The use of recycled materials in new pipe casting reduces waste and conserves resources, making it an environmentally friendly option.

Future Trends in Cast Iron Pipe Casting

As society moves towards more sustainable practices, the future of cast iron pipe casting is looking promising. Innovations in manufacturing techniques, such as 3D printing and advanced alloy compositions, are being explored to enhance the strength and reduce the weight of cast iron pipes while maintaining their exceptional properties.

Moreover, the growing emphasis on infrastructure modernization and green construction practices is likely to drive demand for cast iron pipes. Their recyclability and durability align well with current environmental goals, suggesting that cast iron will continue to play a crucial role in modern engineering.

Conclusion

In summary, cast iron pipe casting remains a cornerstone of manufacturing due to its myriad advantages, including durability, resistance to corrosion, and sound-damping properties. Understanding the casting process and recognizing the potential future trends can help stakeholders make informed decisions in the construction and plumbing industries. As we move forward, cast iron pipes will undoubtedly continue to provide vital solutions to the growing challenges of modern infrastructure.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025