- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ກ.ພ. . 10, 2025 09:48 Back to list

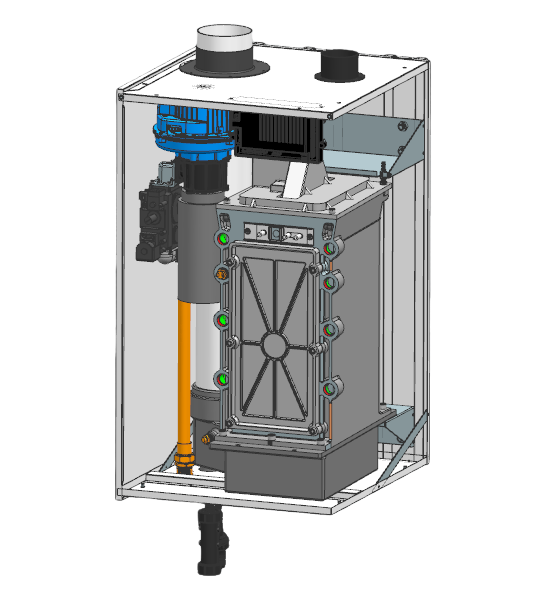

liquid to liquid heat exchanger

Liquid to liquid heat exchangers are pivotal in a variety of industries, known for their efficiency in transferring heat between two fluid streams. These devices are indispensable in sectors ranging from chemical processing to HVAC systems, ensuring optimal thermal management and energy efficiency.

Authoritativeness in the field comes from staying updated with the latest technological advancements and regulatory standards. Modern heat exchangers integrate sophisticated design features such as optimized flow paths and enhanced surface areas, which significantly boost their performance. Attending industry conferences, participating in webinars, and subscribing to trade publications are excellent ways to maintain authoritative knowledge. This continuous learning not only aids in selecting the best systems but also in troubleshooting and improving existing setups. Trustworthiness, a key aspect of a reliable setup, is enhanced by recognizing recognized brands and manufacturers who have a track record of quality and innovation. Investing in systems from reputable sources assures quality and compliance with industry standards. Furthermore, seeking certifications such as ISO 9001 or ASME accreditation can provide additional assurance of a system’s reliability. In conclusion, liquid to liquid heat exchangers are a fundamental component of efficient thermal management in various industries. Drawing from real-world experience and comprehensive expertise, alongside authoritative insights and reliable sources, ensures these systems deliver optimal performance and long-term value. Understanding these facets not only improves operational efficiency but also fosters an environment of trust and reliability among stakeholders. By effectively navigating the complexities of liquid to liquid heat exchangers, companies can enhance their production processes, reduce costs, and maintain a competitive edge in their respective industries.

Authoritativeness in the field comes from staying updated with the latest technological advancements and regulatory standards. Modern heat exchangers integrate sophisticated design features such as optimized flow paths and enhanced surface areas, which significantly boost their performance. Attending industry conferences, participating in webinars, and subscribing to trade publications are excellent ways to maintain authoritative knowledge. This continuous learning not only aids in selecting the best systems but also in troubleshooting and improving existing setups. Trustworthiness, a key aspect of a reliable setup, is enhanced by recognizing recognized brands and manufacturers who have a track record of quality and innovation. Investing in systems from reputable sources assures quality and compliance with industry standards. Furthermore, seeking certifications such as ISO 9001 or ASME accreditation can provide additional assurance of a system’s reliability. In conclusion, liquid to liquid heat exchangers are a fundamental component of efficient thermal management in various industries. Drawing from real-world experience and comprehensive expertise, alongside authoritative insights and reliable sources, ensures these systems deliver optimal performance and long-term value. Understanding these facets not only improves operational efficiency but also fosters an environment of trust and reliability among stakeholders. By effectively navigating the complexities of liquid to liquid heat exchangers, companies can enhance their production processes, reduce costs, and maintain a competitive edge in their respective industries.

Share

Pervious:

Latest news

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025