ທ.ວ. . 30, 2024 01:02 Back to list

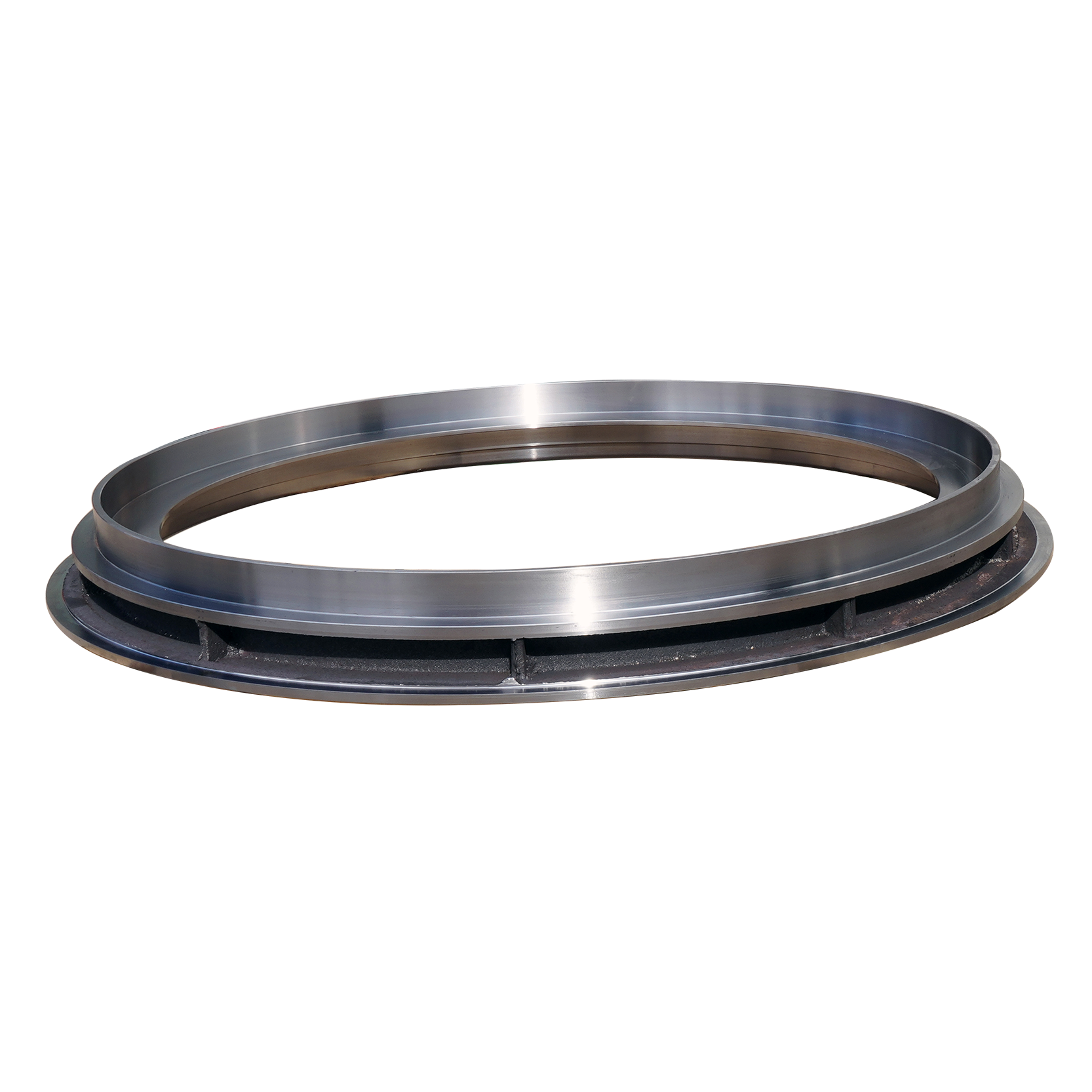

precision casting factory

The Advantages of Precision Casting in Modern Manufacturing

Precision casting, often referred to as investment casting or lost-wax casting, is a sophisticated manufacturing process that has gained significant attention across various industries. This technique offers unparalleled accuracy and surface finish, making it the preferred choice for producing complex parts. In this article, we will explore the benefits of precision casting, how it works, and its applications.

Understanding Precision Casting

Precision casting involves creating a detailed model of a part using a wax pattern. This pattern is coated with a ceramic material to form a mold. Once the mold hardens, the wax is melted away, leaving a hollow cavity that accurately represents the desired part. Molten metal is then poured into this cavity, solidifying to create a component that mirrors the original design with extreme fidelity.

This method is particularly advantageous for producing intricate parts with complex geometries that would be challenging or impossible to achieve through traditional machining methods. The precision casting process allows for remarkable detail, which is essential in industries like aerospace, automotive, medical devices, and jewelry.

Advantages of Precision Casting

1. High Precision and Accuracy One of the standout benefits of precision casting is its capability to produce parts with tight tolerances. This level of accuracy reduces the need for extensive machining after casting, saving both time and costs.

2. Complex Geometries Precision casting can create components with intricate shapes and fine details that are often difficult to achieve with conventional methods. This flexibility allows designers to innovate without fearing manufacturing limitations.

3. Excellent Surface Finish The casting process results in a smooth surface finish, which can sometimes eliminate or reduce the need for secondary processing. A finer surface finish is particularly important for applications requiring aesthetics or minimizing friction.

4. Material Versatility Precision casting is compatible with a wide range of metals, including stainless steel, aluminum, bronze, and titanium. This versatility enables manufacturers to select the best material for their specific requirements.

precision casting factory

5. Waste Reduction Unlike some traditional methods that cut away material from a larger block (subtractive manufacturing), precision casting generates significantly less waste. This eco-friendly aspect is becoming increasingly important in sustainable manufacturing practices.

6. Cost-Effective for Large Runs While the initial setup for precision casting can be higher than other methods, it becomes cost-effective when producing large volumes. The ability to create multiple parts simultaneously in one mold maximizes efficiency.

Applications of Precision Casting

Precision casting has found numerous applications across diverse fields

- Aerospace In aerospace, components such as turbine blades, structural parts, and engine casings benefit from the high strength and lightweight characteristics provided by precision casting.

- Automotive The automotive industry utilizes precision casting for various engine parts, gearboxes, and structural components, where performance and durability are paramount.

- Medical Devices Precision casting is also crucial in the manufacturing of medical instruments and implants, where precision and biocompatibility are essential factors.

- Art and Jewelry In the artistic realm, precision casting allows for exquisite jewelry designs and artistic sculptures, showcasing intricate details that attract attention.

Conclusion

In a world where precision and efficiency are increasingly demanded, precision casting stands out as a superior manufacturing technique. Its ability to produce complex geometries, maintain fine tolerances, and minimize waste makes it invaluable across many industries. As technology continues to advance, we can anticipate even more innovations in precision casting, further enhancing its role in modern manufacturing processes. Whether it's in crafting intricate medical devices or producing lightweight aerospace components, precision casting is transforming the landscape of how we create and build.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025