- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Gru . 04, 2024 17:35 Back to list

Silica Sol Casting Exporters for High-Quality Precision Manufacturing Solutions

Silica Sol Casting Exporters The Future of Precision Manufacturing

In the world of manufacturing, precision is paramount. One of the methods gaining significant traction for its ability to create intricate designs with high dimensional accuracy is silica sol casting. As global demand for high-quality components continues to rise, so does the need for effective silica sol casting exporters who can meet these challenges. This article delves into the intricacies of silica sol casting, its advantages, the role of exporters, and future trends in the industry.

Understanding Silica Sol Casting

Silica sol casting, also known as the lost wax process or investment casting, involves creating a mold from a wax pattern coated in a silica sol. The silica sol is a colloidal solution of silica particles in water, which provides excellent strength and fine detail to the mold. Once the mold is created, the wax is melted away, leaving a precise cavity that is filled with molten metal. This innovative casting technique is particularly favored in industries such as aerospace, automotive, and medical, where components must meet stringent specifications.

Advantages of Silica Sol Casting

One of the most significant advantages of silica sol casting is its ability to produce complex geometries. Traditional casting methods often struggle with intricate designs, leading to limitations in product innovation. However, silica sol casting allows manufacturers to create components with intricate details, thin walls, and fine surface finishes, making it an ideal choice for high-precision applications.

Another key benefit is the enhanced surface finish. The smoothness of the silica sol mold leads to less post-processing work, which can save time and resources. Additionally, this method reduces the likelihood of defects, such as voids and sand inclusions, which are common in conventional casting processes. The result is a higher yield of quality parts, contributing to better overall productivity.

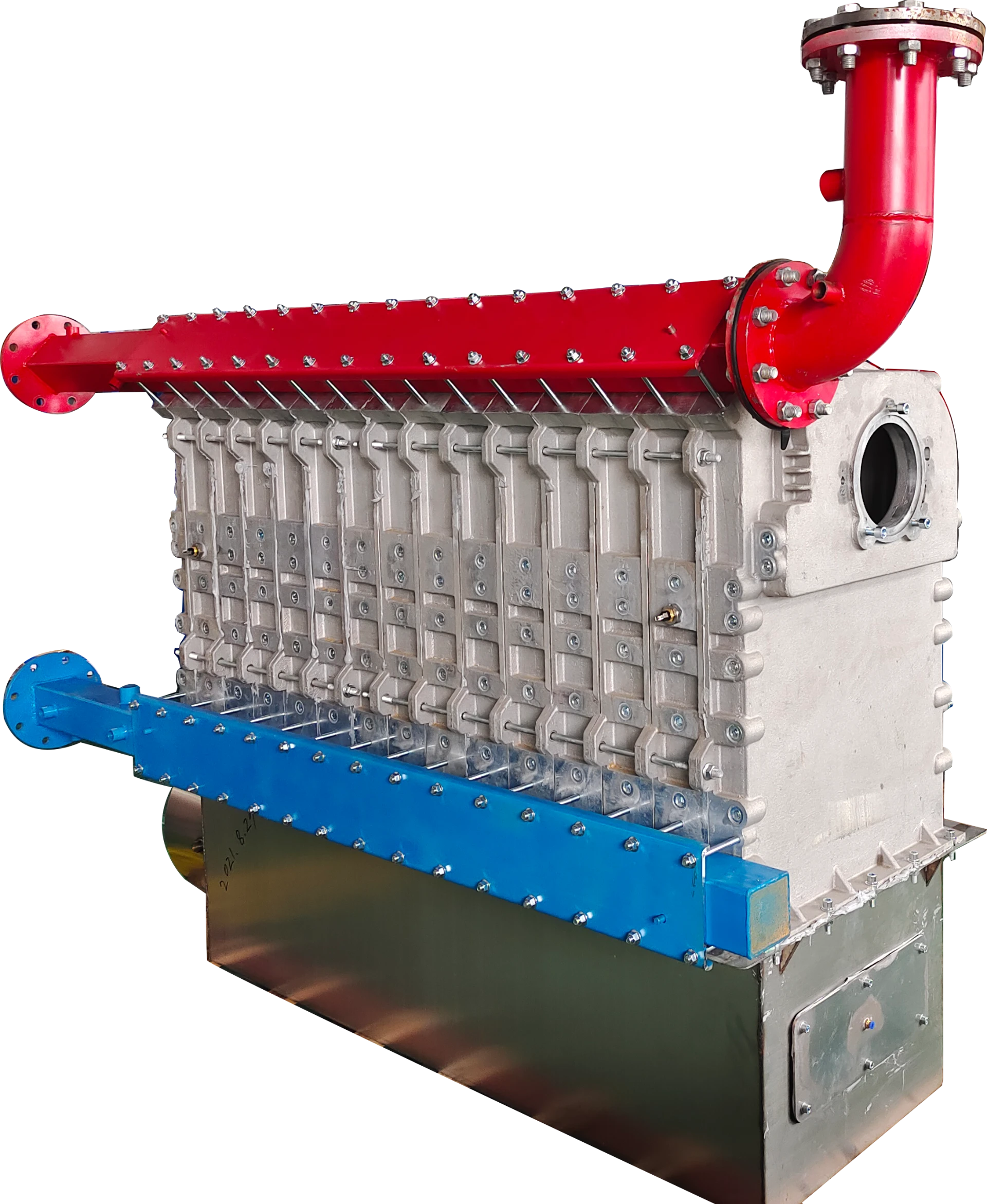

silica sol casting exporters

The Role of Exporters in the Silica Sol Casting Market

As global markets expand and industries grow more interconnected, the role of silica sol casting exporters becomes crucial. These exporters act as a bridge between manufacturers and global clientele, facilitating the distribution of high-quality cast components across borders. They often have extensive knowledge of compliance regulations, ensuring that products meet the necessary safety standards and specifications outlined by various industries.

Moreover, silica sol casting exporters can provide localized support, offering insights into market trends and assisting clients in selecting the best materials and processes for their specific needs. By leveraging their expertise, exporters help manufacturers optimize their production processes and deliver top-notch products to consumers, significantly impacting overall efficiency and profitability.

Future Trends in Silica Sol Casting

The future of silica sol casting looks promising, driven by advancements in technology and increased automation in production processes. As the industry embraces Industry 4.0, the integration of digital technologies and smart manufacturing practices will streamline operations and enhance product quality further.

Moreover, the ongoing demand for lightweight materials in sectors like aerospace and automotive is expected to fuel growth in the silica sol casting market. As manufacturers strive to reduce weight and improve fuel efficiency, they will increasingly turn to precision casting methods to meet these goals.

In conclusion, silica sol casting offers a range of advantages, enabling manufacturers to produce high-quality components with complex designs and superior finishes. The role of silica sol casting exporters is paramount in navigating the global marketplace and ensuring that these state-of-the-art products reach their intended destinations. With the constant evolution of manufacturing technologies and the growing demand for precision components, the future of silica sol casting and its exporters appears bright and full of opportunity.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025