- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Okt . 01, 2024 16:46 Back to list

Exploring the Benefits of ODM Water Glass Sand Casting Techniques for Efficient Production

The Role of ODM Water Glass in Sand Casting An Overview

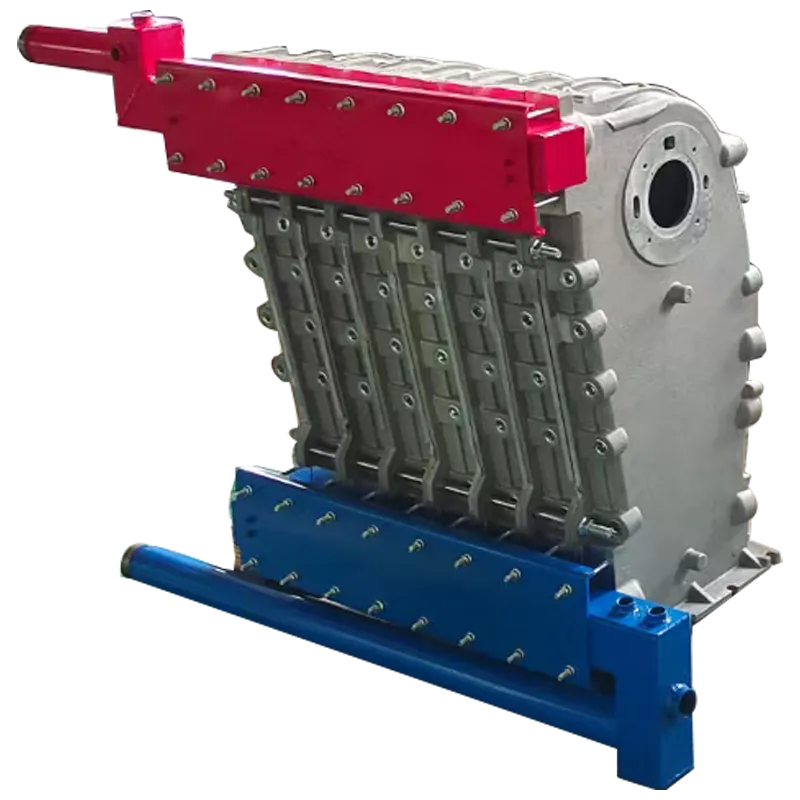

Sand casting, a widely used manufacturing process, has been integral to various industries for producing complex metal components. One of the key aspects that significantly enhance the quality and efficiency of sand casting is the molding material used, and among these, ODM water glass stands out as a vital component. This article explores the characteristics of ODM water glass, its application in sand casting, and the benefits it brings to the casting process.

Understanding ODM Water Glass

ODM water glass, also known as sodium silicate, is a versatile chemical compound that appears as a viscous liquid and can also be found in solid form. It is composed of sodium oxide and silica, which are combined in an alkaline solution. Its unique properties, including excellent adhesion, high-temperature resistance, and water solubility, make it a popular choice in various applications, including the foundry industry.

Applications in Sand Casting

In sand casting, the success of producing high-quality metal parts largely depends on the quality of the mold. ODM water glass is primarily used as a binding agent in making molds and cores from sand. When combined with a specific catalyst, usually an acidic hardener, it forms a strong bond that solidifies the sand particles, creating a durable and stable mold.

One of the advantages of using ODM water glass in sand casting is its ability to produce molds with intricate details and smooth surfaces. The liquid form of water glass allows it to penetrate the sand grains, ensuring better coating and adhesion. This results in improved dimensional accuracy of the final castings, which is crucial for industries that require parts with tight tolerances.

Benefits of Using ODM Water Glass in Sand Casting

odm water glass sand casting

1. Environmental Benefits ODM water glass is considered eco-friendly compared to traditional organic binders that may emit harmful fumes during the curing process. Its usage aligns with the industry's growing emphasis on sustainability and reducing environmental impact.

2. High Thermal Stability Sand molds made with ODM water glass demonstrate excellent thermal stability. This property enables them to withstand high temperatures during the metal pouring process without deforming, ensuring the integrity of the casting.

3. Improved Mechanical Properties The molds created with ODM water glass possess enhanced mechanical properties, such as increased strength and resilience. This characteristic contributes to better handling during the casting process and results in fewer defects in the final products.

4. Cost-Effectiveness Utilizing ODM water glass can also be a cost-effective solution. It reduces the need for additional materials often required in traditional molding methods, thus lowering overall production costs.

5. Versatility ODM water glass can be adjusted in concentration to cater to different casting requirements. This versatility allows foundries to modify properties such as setting time and strength according to specific production needs.

Conclusion

In sum, ODM water glass plays a pivotal role in the sand casting process by enhancing mold quality, detail accuracy, and mechanical strength while promoting environmental sustainability. As industries continue to innovate and seek efficient, reliable methods of production, the use of ODM water glass is likely to grow, paving the way for improvements in casting technology. Foundries that adopt this advanced material can expect not only enhanced product quality but also reduced environmental footprints in their manufacturing processes, ensuring a sustainable future for the industry.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025