- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Сеп . 22, 2024 22:43 Back to list

carbon steel lost wax casting suppliers

The Growing Market for Carbon Steel Lost Wax Casting Suppliers

The manufacturing industry is constantly evolving, driven by advancements in technology and an increasing demand for high-quality components. One of the processes gaining traction is lost wax casting, particularly with carbon steel. This method offers superior precision and complexity, making it an appealing choice for various applications, from automotive to aerospace. As a result, the market for carbon steel lost wax casting suppliers is rapidly expanding.

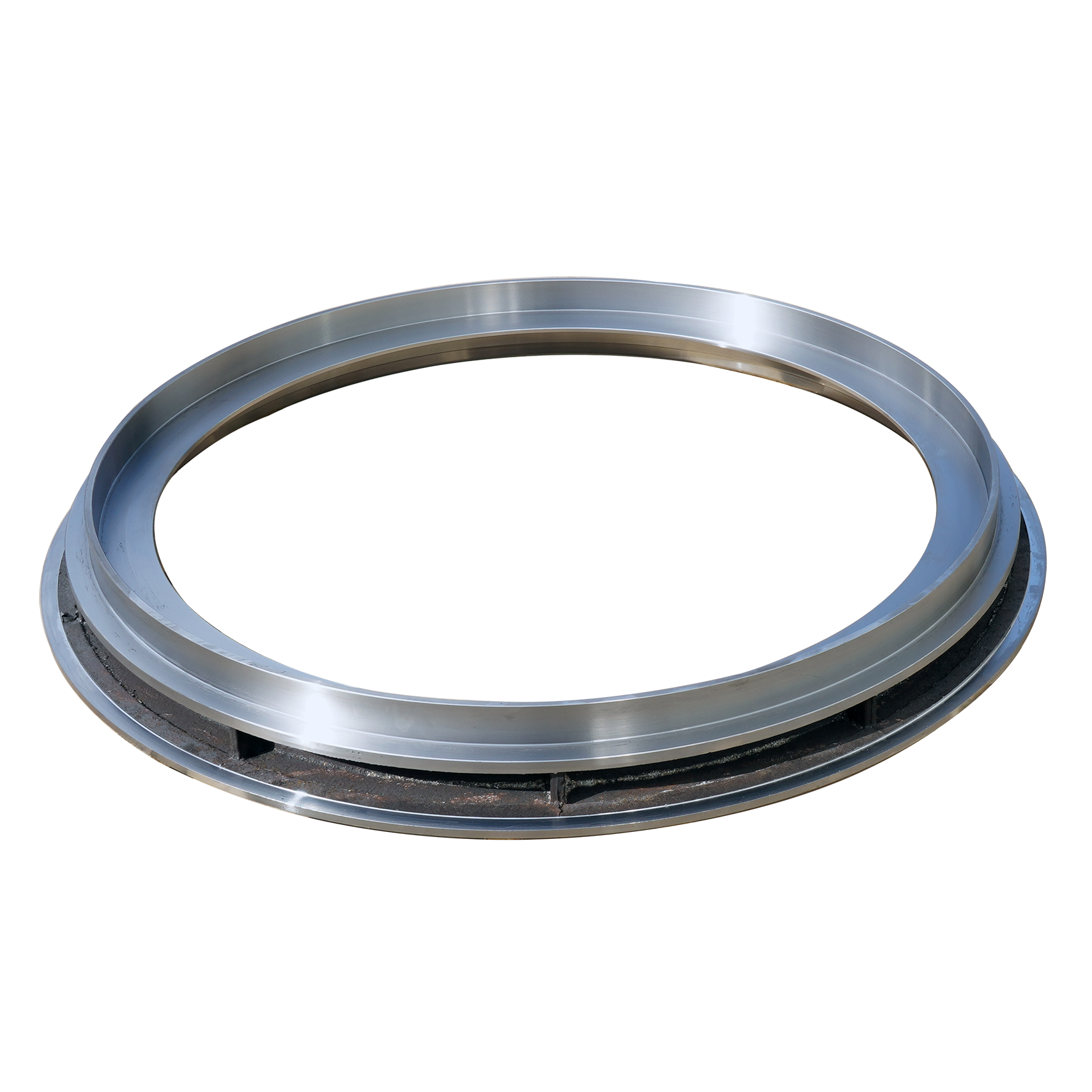

Lost wax casting, also known as investment casting, is an ancient method that has been refined over the centuries. It involves creating a wax model of the desired part, which is then coated in a ceramic shell. Once the shell hardens, the wax is melted away, leaving a cavity into which molten metal, such as carbon steel, is poured. This process allows for intricate designs and tight tolerances, which are often challenging to achieve with other casting techniques.

Carbon steel is a preferred material for many industrial applications due to its strength, durability, and excellent mechanical properties. Its versatility makes it suitable for manufacturing a wide range of products, including gears, valves, and various machine components. Carbon steel lost wax casting suppliers are essential in ensuring that the cast parts meet stringent quality standards and specifications.

carbon steel lost wax casting suppliers

As industries worldwide continue to prioritize efficiency and precision, the demand for lost wax casting has surged. This increase can be attributed to several factors. First, the ability to produce complex shapes without the need for extensive machining saves both time and materials, contributing to cost-effectiveness. Additionally, lost wax casting produces components with smooth surfaces, reducing the need for secondary finishing processes.

In this expanding market, businesses are faced with the challenge of choosing reliable carbon steel lost wax casting suppliers. Quality, experience, and technical expertise are critical factors in making this decision. Reputable suppliers often employ advanced technologies and skilled labor to ensure high-quality outputs. They also invest in rigorous quality control systems to meet industry standards and client expectations.

Furthermore, many suppliers are adopting sustainable practices to reduce their environmental footprint. This commitment to sustainability is becoming increasingly important for customers who prioritize environmentally friendly production methods. By integrating eco-friendly practices into the lost wax casting process, suppliers not only enhance their market appeal but also contribute to a greener manufacturing landscape.

In conclusion, the market for carbon steel lost wax casting suppliers is thriving as industries seek high-quality, precise components. The benefits of lost wax casting, coupled with the versatility of carbon steel, position this method as a preferred choice in various sectors. As the demand continues to grow, suppliers who emphasize quality, innovation, and sustainability will likely lead the way, ensuring they meet the ever-evolving needs of their customers. The future of lost wax casting in carbon steel looks promising, making it an exciting area of growth in the manufacturing industry.

-

Silica Sol Casting Supplier – Custom, ODM & Buy Services High Precision Casting Solutions

NewsJun.10,2025

-

High-Performance AODD Pumps for Diverse Applications Buy Custom & ODM AODD Solutions Online

NewsJun.10,2025

-

High-Quality Casting Machinery Parts Custom & ODM Services Available

NewsJun.10,2025

-

Premium Punching Cement Concrete Pipe Mold Pallets Custom ODM Available

NewsJun.10,2025

-

Premium Cast Aluminum Silicon Radiator Castings For Sale

NewsJun.10,2025

-

Custom Cast Steel Pipe Mold Pallet for Durable Precision

NewsJun.10,2025