- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Јан . 11, 2025 11:03 Back to list

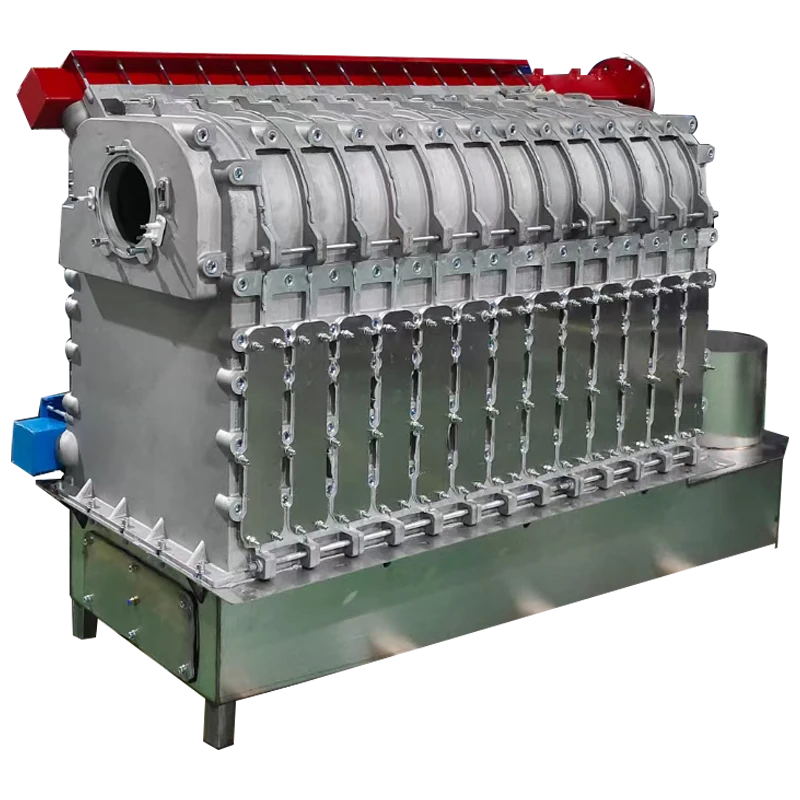

making a mold for aluminum casting

Choosing the right bottom ring for a stamping concrete pipe mold is an essential element in the manufacturing process of high-quality concrete pipes. With years of hands-on experience in the industry, I can confidently guide you through selecting the ideal bottom ring - a critical component that not only influences the efficiency of production but also determines the durability and performance of the final product.

In the realm of expertise, consulting with industry professionals or specialists can provide invaluable insights into the selection and maintenance of bottom rings. Their years of knowledge and technical know-how can help to pinpoint the most suitable options that align with your specific production goals and environmental conditions. Engaging with professional networks and forums can also aid in staying informed about the latest advancements in materials and technology improvements. Trustworthiness is crucial when selecting suppliers and manufacturers for concrete pipe mold components. Establishing trust with a reputable supplier guarantees not only the quality of the bottom ring but also reliable after-sales support and customer service. Supplier transparency in manufacturing practices and adherence to international standards can further build confidence in their products. Trust is reinforced through clear communication, availability of comprehensive technical documentation, and opportunities for product testing and validation before full-scale implementation. Ultimately, the choice of a bottom ring for a stamping concrete pipe mold should reflect a balance of technical expertise, material durability, design flexibility, and supplier reliability. This balanced approach promises to enhance production performance and ensure the longevity and quality of the concrete pipes produced, thus supporting successful infrastructure projects and long-term operational goals.

In the realm of expertise, consulting with industry professionals or specialists can provide invaluable insights into the selection and maintenance of bottom rings. Their years of knowledge and technical know-how can help to pinpoint the most suitable options that align with your specific production goals and environmental conditions. Engaging with professional networks and forums can also aid in staying informed about the latest advancements in materials and technology improvements. Trustworthiness is crucial when selecting suppliers and manufacturers for concrete pipe mold components. Establishing trust with a reputable supplier guarantees not only the quality of the bottom ring but also reliable after-sales support and customer service. Supplier transparency in manufacturing practices and adherence to international standards can further build confidence in their products. Trust is reinforced through clear communication, availability of comprehensive technical documentation, and opportunities for product testing and validation before full-scale implementation. Ultimately, the choice of a bottom ring for a stamping concrete pipe mold should reflect a balance of technical expertise, material durability, design flexibility, and supplier reliability. This balanced approach promises to enhance production performance and ensure the longevity and quality of the concrete pipes produced, thus supporting successful infrastructure projects and long-term operational goals.

Share

Pervious:

Next:

Latest news

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025