- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ное . 10, 2024 16:50 Back to list

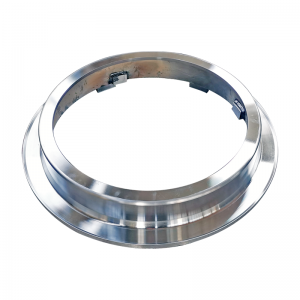

Stainless Steel Component Manufacturing Facilities for High-Quality Industrial Solutions

Stainless Steel Parts Factories The Backbone of Modern Manufacturing

In the world of industrial production, stainless steel parts play a crucial role across various sectors, from automotive to aerospace, and from medical devices to consumer goods. The factories dedicated to producing these stainless steel components are not merely manufacturing plants; they are the backbone of modern manufacturing, driving innovation, efficiency, and quality in an ever-evolving market.

Stainless steel, renowned for its durability, corrosion resistance, and aesthetic appeal, has become a material of choice in many applications. Stainless steel parts factories are equipped with advanced technologies and skilled labor to ensure high-quality production standards. These facilities utilize state-of-the-art machinery, including CNC (Computer Numerical Control) machines, laser cutting tools, and advanced welding technologies, to produce precise and complex parts that meet stringent industry requirements.

One of the primary advantages of stainless steel is its versatility. In automotive manufacturing, for example, stainless steel parts are used in exhaust systems, fuel tanks, and structural components due to their ability to withstand high temperatures and resist rust and corrosion. In the aerospace industry, the lightweight and strength properties of stainless steel make it an excellent choice for critical components that require both durability and reliability under extreme conditions. Likewise, in the medical sector, stainless steel is preferred for surgical instruments and implants, as it can be sterilized and is less likely to provoke adverse reactions in the human body.

The production process in stainless steel parts factories is meticulous and involves several key steps. First, raw materials are sourced, commonly in the form of stainless steel sheets, rods, or bars. These materials undergo various processes such as cutting, bending, and shaping to create the desired components. Quality control is a paramount aspect of manufacturing; throughout the process, rigorous inspections are conducted to ensure that every part meets predefined specifications.

stainless steel parts factories

Moreover, many stainless steel parts factories are shifting towards sustainable practices. The manufacturing industry is witnessing a growing emphasis on reducing waste and energy consumption. Many factories are adopting lean manufacturing principles and investing in environmentally friendly technologies that minimize their carbon footprint. For instance, recycling scrap stainless steel not only reduces material costs but also contributes to a more sustainable production model. Factories are also exploring renewable energy sources, such as solar and wind power, to operate their machinery and reduce dependence on fossil fuels.

The global market for stainless steel parts continues to expand, driven by increasing demand in emerging economies and technological advancements. As manufacturers strive for innovation, stainless steel parts factories are evolving to incorporate automation and digital technologies such as the Internet of Things (IoT) and artificial intelligence (AI). These technologies optimize production workflows, enhance product quality, and enable real-time monitoring, thereby improving overall efficiency and responsiveness to market changes.

Moreover, the competitive landscape encourages stainless steel parts manufacturers to focus on customer-centric approaches. Customization is becoming increasingly important, as clients seek tailored solutions that fit their specific needs. Factories are leveraging advanced design software and rapid prototyping techniques to deliver bespoke components rapidly, ensuring higher levels of customer satisfaction.

In conclusion, stainless steel parts factories are indispensable to the fabric of modern manufacturing, providing the essential components that drive various industries forward. With their commitment to quality, innovation, and sustainability, these factories are not only meeting current demands but are also paving the way for the future of industrial production. As technology continues to evolve, and as the world places greater emphasis on sustainability and customization, stainless steel parts factories will undoubtedly play a pivotal role in shaping the landscape of manufacturing for years to come. Whether in the form of automotive parts, medical devices, or consumer products, the significance of stainless steel parts—and the factories that produce them—cannot be overstated.

-

Premium Cast Aluminum Parts Casting - Custom & ODM Solutions Available

NewsJun.08,2025

-

Premium Custom Heat Exchanger for Low NOx Condensing Boilers Efficient

NewsJun.08,2025

-

Domestic Hot Water Heat Exchanger - Customizable, High-Efficiency Solutions

NewsJun.08,2025

-

Precision Sand Casts Custom Quality Durable & Reliable

NewsJun.08,2025

-

Custom Low Nitrogen Domestic Hot Water Condensing Gas Boiler

NewsJun.08,2025

-

Premium Reinforced Concrete Pipe Mold/Mould Pallet Durable & Efficient Design

NewsJun.07,2025