ഡിസം . 05, 2024 15:39 Back to list

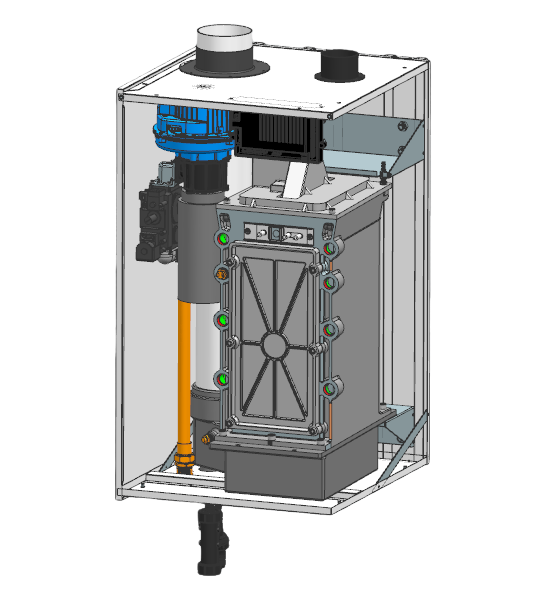

gas fired boiler made from cast silico aluminum heat exchanger manufacturer

The Advantages of Cast Silico Aluminum Heat Exchangers in Gas-Fired Boilers

In the realm of energy production and heating systems, gas-fired boilers play a pivotal role in providing efficient heating and hot water solutions for both residential and commercial applications. A critical component of these boilers is the heat exchanger, which is responsible for transferring heat from the combustion gas to the water used for heating. Among various materials, cast silico aluminum has emerged as a remarkable choice for manufacturing heat exchangers in gas-fired boilers. This article explores the advantages of using cast silico aluminum in these applications.

High Thermal Conductivity

One of the primary advantages of cast silico aluminum is its excellent thermal conductivity. The alloy, primarily composed of silicon and aluminum, can efficiently transfer heat from the combustion process to the water, resulting in improved energy efficiency. This property allows gas-fired boilers to reach higher efficiency levels, maximizing heat output while minimizing energy consumption. With energy costs rising, this efficiency is crucial for both homeowners and businesses aiming to reduce their operational costs.

Corrosion Resistance

Heat exchangers often operate in harsh environments where they are exposed to a variety of corrosive elements, including water, combustion residues, and other byproducts. Cast silico aluminum offers exceptional corrosion resistance, which significantly extends the lifespan of heat exchangers in gas-fired boilers. The alloy is less prone to rust and deterioration compared to traditional materials such as steel, making it an ideal choice for long-term installation. This durability translates to lower maintenance costs and reduced downtime due to repairs or replacements.

Lightweight Design

gas fired boiler made from cast silico aluminum heat exchanger manufacturer

Another significant benefit of cast silico aluminum is its lightweight nature. Compared to other metals commonly used in heat exchangers, such as copper or steel, aluminum alloys can significantly reduce the overall weight of the boiler system. This reduction in weight can lead to more straightforward installation processes and less structural support required, which is particularly advantageous in older buildings or those with weight restrictions. Additionally, lighter units typically facilitate easier handling and transport, benefiting manufacturers and installers alike.

Enhanced Thermal Efficiency

The design flexibility afforded by cast silico aluminum allows for intricate and efficient heat exchanger designs. Innovative configurations can be created to increase surface area exposure, resulting in improved heat transfer rates. Enhanced thermal efficiency enables these gas-fired boilers to run at optimal performance levels, thus contributing to lower emissions. As environmental awareness grows and regulations tighten, the combination of efficiency and reduced emissions becomes increasingly important.

Cost-Effectiveness

While the initial investment in a cast silico aluminum heat exchanger may be competitive, the overall cost-effectiveness becomes apparent over time. Due to their durability and resistance to corrosion and wear, these heat exchangers require less frequent replacement than those made from other materials. Furthermore, the energy savings gained from improved thermal efficiency can result in significant financial benefits for users, offsetting the cost of investment in the long run.

Conclusion

In conclusion, cast silico aluminum represents a superior choice for manufacturers of heat exchangers in gas-fired boilers, combining high thermal conductivity with durability, lightweight properties, enhanced thermal efficiency, and cost-effectiveness. As the demand for efficient and sustainable heating solutions continues to increase, the adoption of advanced materials like cast silico aluminum will likely play a crucial role in shaping the future of heating technology. For manufacturers seeking to enhance the performance and longevity of their products, investing in cast silico aluminum heat exchangers is a strategic move toward meeting modern energy demands.

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025