- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ആഗ . 03, 2025 01:00 Back to list

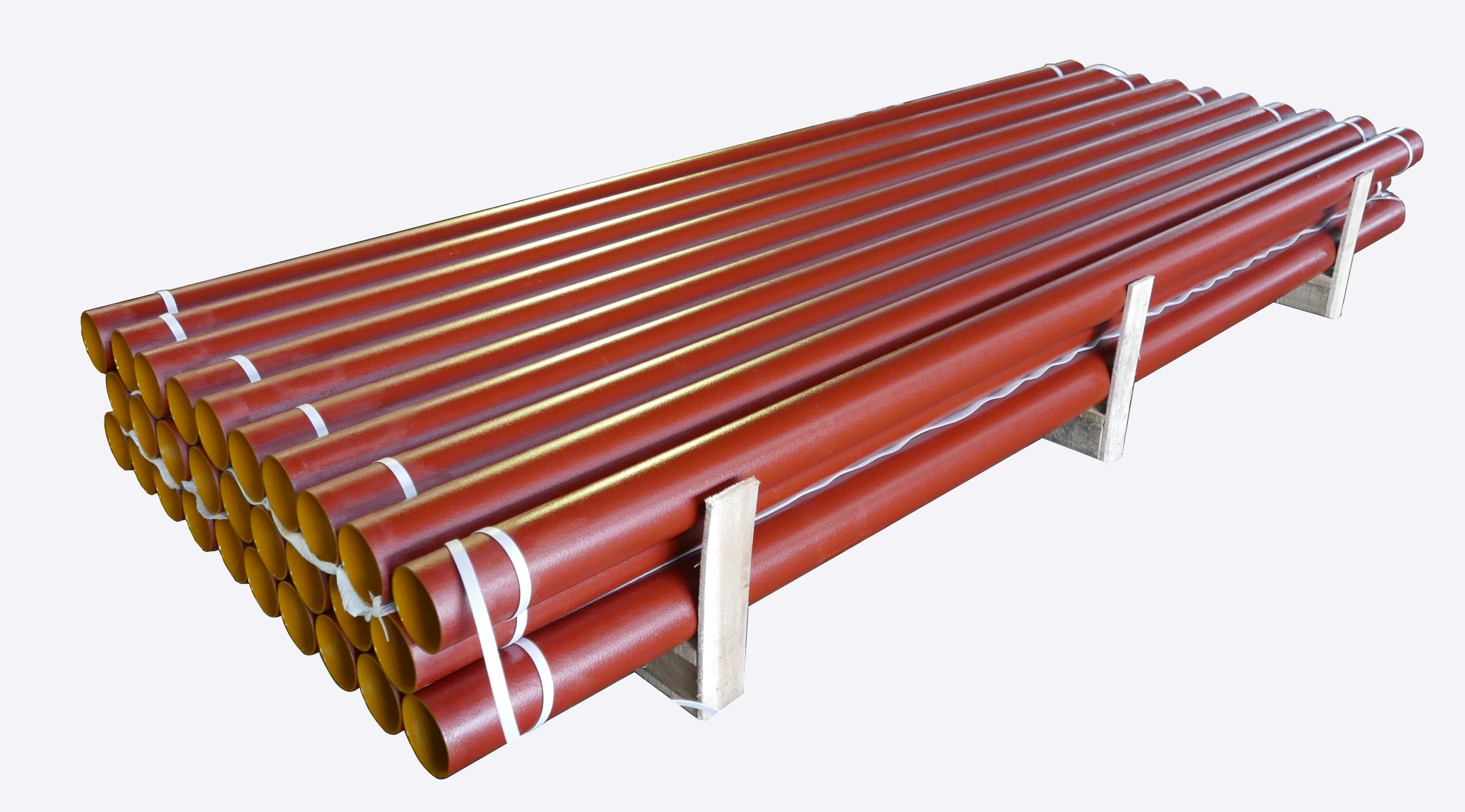

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

As urban infrastructure accelerates worldwide, selecting reliable pipelines for water distribution and drainage becomes crucial. Cast iron water main pipe solutions remain the backbone of municipal engineering, industrial manufacturing, and building systems due to their superior mechanical properties, remarkable corrosion resistance, and unrivaled life span. This article explores advanced cast iron water main pipe technology, focusing on DIN EN877 Cast Iron Pipes and Fittings, Gray Cast Iron Product Service, China Original Factory (cast iron water main pipe) and key industry keywords: centrifugally cast iron, bell and spigot ductile iron pipe, cast iron conduit, and more.

1. Industry Overview & Trends: Cast Iron Water Main Pipes

Cast iron water main pipe has been fundamental to global water supply networks for over 150 years. Today, cutting-edge manufacturing—especially centrifugally cast iron pipe technologies—meets rising demands for:

- Extended service life: median lifespan exceeds 80-100 years (source: AWWA Journal).

- Efficient corrosion protection: thanks to improved gray iron alloys and interior/exterior lining technologies (epoxy, cement).

- Compliance with international standards: e.g., EN877, ISO 2531, ANSI/AWWA C150/C151.

- Sustainable manufacturing: over 95% of the iron content typically sourced from recycled materials.

The global market for cast iron water main pipes in 2023 surpassed USD 6.4 billion, with Asia-Pacific representing over 35% of new pipeline projects (data: GrandViewResearch).

The global market for cast iron water main pipes in 2023 surpassed USD 6.4 billion, with Asia-Pacific representing over 35% of new pipeline projects (data: GrandViewResearch).

2. Key Technologies and Material Advantages

- Centifugally Cast Iron: Utilizes centrifugal force during casting, yielding dense pipe walls and evenly distributed graphite flakes—substantially improving pressure rating and crack resistance versus sand cast iron pipes.

- Ductile Iron (DI): Incorporates magnesium or cerium in molten iron, forming spheroidal graphite, which increases flexibility, yield strength (typically 420–520 MPa), and impact resistance (bell and spigot ductile iron pipe excels here).

- Gray Cast Iron: Classic material for drainage and conduit due to excellent vibration damping, machinability, and cost-effectiveness. Often used for cast iron conduit and cast drain pipe installations.

Material Comparison Table: Cast Iron vs Ductile Iron Pipes

| Parameter | Gray Cast Iron Pipe | Ductile Iron Pipe |

|---|---|---|

| Material Microstructure | Lamelar graphite; brittle | Spheroidal graphite; ductile |

| Yield Strength | 150–200 MPa | 420–520 MPa |

| Ultimate Tensile Strength | 200–300 MPa | 500–700 MPa |

| Impact Toughness | Low | High |

| Corrosion Resistance | Moderate (with lining/cover) | Excellent (with lining/cover) |

| Average Life Cycle | 70–90 years | 100+ years |

| Common Uses | Drainage, conduit, non-pressure | Water supply, mains, pressure lines |

3. Manufacturing Process: Cast Iron Water Main Pipe

DIN EN877 Cast Iron Pipes and Fittings Manufacturing Diagram

→ Raw Material Selection: High-purity iron scrap + alloys (≥95% recycled iron)

→ Melting: Electric induction furnace, accurate temperature and composition control

→ Centrifugal Casting: Molten iron spun at 800-1000 RPM in water-cooled molds

→ CNC Finishing: Automated trimming of pipe ends, precise internal diameter

→ Surface Treatments: Internal epoxy or cement mortar lining; external zinc-rich and bitumen coatings

→ Quality Inspection: EN877, ISO 2531, ANSI/AWWA standards—hydrostatic testing, ultrasonic & X-ray

→ Packing & Logistics: Automated stacking, container111ized shipments

4. DIN EN877 Cast Iron Pipe – Product Specifications

| Standard | Diameter Range (DN) | Wall Thickness (mm) | Length (m) | Coating | Hydro Test Pressure | ISO/EN Certification |

|---|---|---|---|---|---|---|

| EN877 | DN40 – DN400 | 3.0 – 10.0 | 3.0 | Epoxy lining, bitumen/zinc external | 5–15 bar | ISO 2531, EN 877 |

5. Application Scenarios & Success Cases

Cast iron water main pipe systems are crucial in:

- Municipal Water Networks: Resilient backbone for city water supply—high-pressure mains, distribution lines (London, Paris, Beijing projects).

- Industrial Plants: Effluent, chemical, and fire-fighting service pipes in petrochemical and metallurgical sectors.

- Commercial & Residential Drainage: EN877-certified cast iron drain pipes for sale mitigate acoustic noise and ensure non-flammable, leak-resistant waste removal.

- Bridge, Subway, & Tunnel Projects: Cast iron conduit protects electrical/data lines from hazards.

Client Feedback Example: Industrial Project

“After switching to DIN EN877 cast iron pipes for our steel plant, leak rates decreased by 80% and long-term maintenance costs dropped by 37%. Conforms perfectly to EN877 load-bearing requirements; outstanding performance in high-salinity, industrial wastewater removal.”

—Mr. Wang, Project Manager, Wuhan Metallurgy Group (2022)

6. Manufacturer Comparison: China Original Factory vs. Competitors

| Attribute | DIN EN877 China Original Factory | European Producer (EU Standard) | US Top Brand |

|---|---|---|---|

| Standard Compliance | EN877, ISO 2531, ANSI C151 | EN877/ISO | ANSI/AWWA, ASTM |

| Diameter Range | DN40 – DN400 | DN100 – DN400 | DN80 – DN1200 |

| Custom Solutions (OEM/ODM) | Yes (design, markings, coatings) | Limited | Standard only |

| MOQ (Min Order Qty) | Flexible (20 tons+) | Strict (50+ tons) | 20+ tons |

| Lead Time | 15–30 days | 30–50 days | 20–40 days |

| Testing/Documentation | Hydrostatic, X-ray, 3.1 Cert | Mechanical, Hydrostatic | Hydrostatic |

| Cooperation Examples | China National Petroleum, Metro Beijing | Metro Paris | New York Water Dept. |

7. Customization & Engineering Support

- OEM/ODM pipe markings and length: Engraving customer logo, project spec code, or custom paint colors.

- Lining Options: Epoxy (ISO 15745), Bitumen, Cement (DIN 2614) for optimal corrosion protection.

- Joint Selection: Push-fit, socket/bell & spigot, grooved—compatible with both bell and spigot ductile iron pipe and gray iron variants.

- Ancillary Fittings: Wide assortment—bends, tees, couplings, and more, all EN877 certified.

- On-site Technical Support: Pre-install site analysis, installation training, after-sales inspection.

- Global Logistics Network: Containerized or bulk delivery, DDP available to 120+ countries.

8. Certifications, Test Data & Reliability

- Certifications: EN877, ISO 2531, ISO 9001, SGS, and CE marking. Third-party audited with annual compliance checks.

-

Product Test Data (Typical):

Test Standard Value Hydrostatic Pressure EN877/ISO 2531 15 bar (no leakage/rupture, 3hr) Coating Adhesion ISO 21809-3 >6 MPa Salt Spray Corrosion (500hr) ISO 9227 No rust or loss Impact Test (pipe) EN877 <1.0% visible defect

9. Delivery, Warranty & After-sales Service

- Lead Time: 15–30 business days after formal order & deposit.

- Warranty: Standard 24-month factory warranty. Service life—85+ years in typical installations.

- After-sales Support: 24h technical response, on-site troubleshooting, free replacement for quality faults.

- Customer Protection: Full QC inspection record, 3.1 certificate attached to each shipment.

- Support Channels: Email, WhatsApp, WeChat, telephone—global support coverage.

10. Professional FAQ — Cast Iron Water Main Pipe Technology

Q1: What is the difference between centrifugally cast iron pipe and sand cast iron pipe?

A: Centrifugally cast pipes are made by spinning molten iron at high speed in molds, ensuring solid, denser walls with uniform thickness—ideal for higher pressure water main applications. Sand-cast pipes (now rarely used) tend to have uneven walls and lower mechanical strength.

Q2: What are the common joint types for connecting cast iron water main pipes?

A: The leading joint types are: push-fit (rubber gasketed), bell and spigot (with gasket or lead), flanged, and mechanical couplings. EN877 pipes, in particular, support rapid push-fit assemblies for leak-free installation.

Q3: How is corrosion resistance achieved in modern cast iron water main pipe systems?

A: Corrosion resistance results from dual layer protection. Internally: cement or high-performance epoxy linings prevent erosion by water/chemicals. Externally: zinc-rich coatings and bitumen or PU shields block soil/salt attack, extending pipe life far beyond bare metal.

Q4: Which standards apply to cast iron and ductile iron pipes for water mains?

A: Principal standards include EN877 (Europe), ISO 2531 (International), ANSI/AWWA C150/C151/C110 (USA), and local codes. These regulate chemical composition, hydrostatic testing, coatings, straightness, markings, and joint integrity.

Q5: What is the difference between cast iron drain pipe and cast ductile iron pipe?

A: Cast iron drain pipe (gray iron) is intended for above-ground, non-pressurized drainage and conduit—known for excellent sound attenuation and low combustibility. Ductile iron pipes handle higher pressure, underground, or external water supply jobs, thanks to their impressive tensile/impact strength.

Q6: What should I know before I buy cast iron pipe or buy ductile iron pipe for major projects?

A: Confirm the project’s applicable design pressure, chemical exposure, length and diameter requirements, required certifications (EN877 or others), and site installation conditions. Request complete documentation, test certificates, and if needed, custom marking or specific coating options from your supplier.

Q7: Are cast iron water main pipe solutions suitable for high-salinity coastal or industrial wastewater environments?

A: Yes, provided you select epoxy-lined, zinc/PU coated pipes in line with DIN EN877/ISO specs. Many real-world deployments exist in petrochemical, coastal, and metro projects attesting to the product's durability against aggressive media.

11. Purchasing & Integration Steps

- Submit inquiry at the cast iron water main pipe product page.

- Share project specification and drawings for accurate BOQ (Bill of Quantity).

- Receive quotation, technical data sheets, reference test certificates.

- Confirm order and technical requirements, arrange factory inspection if required.

- Production, quality checks, packaging, and ready for shipment.

- Receive goods, schedule on-site technical support for large projects.

12. References & Industry Insights

- AWWA: Water Main Pipe Materials Forum

- Analysis of Failure in Gray and Ductile Iron Pipes in Water Supply Networks

- Durability Evaluation of Cast Iron Pipes in Buried Environments (ScienceDirect, 2022)

- Ductile Iron Pipes Market Size, Share, & Trends (GrandViewResearch)

- EN877 Cast Iron Pipe Specification (Industry Technical Guide)

Content compiled with reference to standards (EN877/ISO2531/ANSI), industry associations, and direct manufacturing data from China Original Factory.

For technical advice or detailed spec sheets, contact our experts.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025