ഫെബ്രു . 10, 2025 21:29 Back to list

CONCRETE PIPE MOLD PALLETS

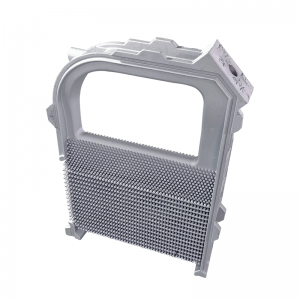

Water-to-water plate heat exchangers have become indispensable in various industrial and commercial sectors due to their efficiency and reliability. These devices are pivotal in transferring heat between two water streams, ushering in a multitude of benefits including energy savings, effective thermal management, and reduced environmental impact.

Authoritativeness Industry Standards and Best Practices Manufacturers adhere to stringent industry standards set forth by entities such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO). These standards ensure that plate heat exchangers meet essential safety, efficiency, and environmental benchmarks. Users are encouraged to prioritize certified units, which are manufactured following rigorous testing and quality assurance processes. Additionally, best practices suggest regular maintenance checks—such as cleaning and inspecting for plate fouling—to extend lifespan and efficiency. Trustworthiness Proven Track Record and Reliability The track record of water-to-water plate heat exchangers speaks volumes about their reliability. Case studies reveal that once integrated, these units consistently perform with minimal downtime and maintenance issues. They offer a sustainable solution that is not only cost-effective but also aligned with green technology goals. With the adaptability to various scales and processes, they represent a trustworthy choice for industries aiming to optimize thermal systems. Future of Water-to-Water Plate Heat Exchangers As industries move towards more sustainable practices, the role of water-to-water plate heat exchangers will likely expand. Emerging technologies such as IoT integration and real-time monitoring can further enhance their performance, providing data-driven insights and predictive maintenance capabilities. Innovations in materials and design will continue to push the envelope, making these devices even more integral to energy efficiency strategies across sectors. In conclusion, water-to-water plate heat exchangers stand as a cornerstone in thermal management solutions. Their design, supported by rich experience, expertise, and adherence to high standards, underscores their importance. For industries eager to improve energy efficiency, control costs, and support environmental sustainability, these exchangers present a verified and trusted method to achieve these goals. By investing in high-quality units, businesses not only secure operational improvements but also contribute positively to broader ecological objectives, aligning with modern energy policies and consumer expectations.

Authoritativeness Industry Standards and Best Practices Manufacturers adhere to stringent industry standards set forth by entities such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO). These standards ensure that plate heat exchangers meet essential safety, efficiency, and environmental benchmarks. Users are encouraged to prioritize certified units, which are manufactured following rigorous testing and quality assurance processes. Additionally, best practices suggest regular maintenance checks—such as cleaning and inspecting for plate fouling—to extend lifespan and efficiency. Trustworthiness Proven Track Record and Reliability The track record of water-to-water plate heat exchangers speaks volumes about their reliability. Case studies reveal that once integrated, these units consistently perform with minimal downtime and maintenance issues. They offer a sustainable solution that is not only cost-effective but also aligned with green technology goals. With the adaptability to various scales and processes, they represent a trustworthy choice for industries aiming to optimize thermal systems. Future of Water-to-Water Plate Heat Exchangers As industries move towards more sustainable practices, the role of water-to-water plate heat exchangers will likely expand. Emerging technologies such as IoT integration and real-time monitoring can further enhance their performance, providing data-driven insights and predictive maintenance capabilities. Innovations in materials and design will continue to push the envelope, making these devices even more integral to energy efficiency strategies across sectors. In conclusion, water-to-water plate heat exchangers stand as a cornerstone in thermal management solutions. Their design, supported by rich experience, expertise, and adherence to high standards, underscores their importance. For industries eager to improve energy efficiency, control costs, and support environmental sustainability, these exchangers present a verified and trusted method to achieve these goals. By investing in high-quality units, businesses not only secure operational improvements but also contribute positively to broader ecological objectives, aligning with modern energy policies and consumer expectations.

Share

Pervious:

Latest news

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025