- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

10 сар . 06, 2024 22:39 Back to list

casting product manufacturer

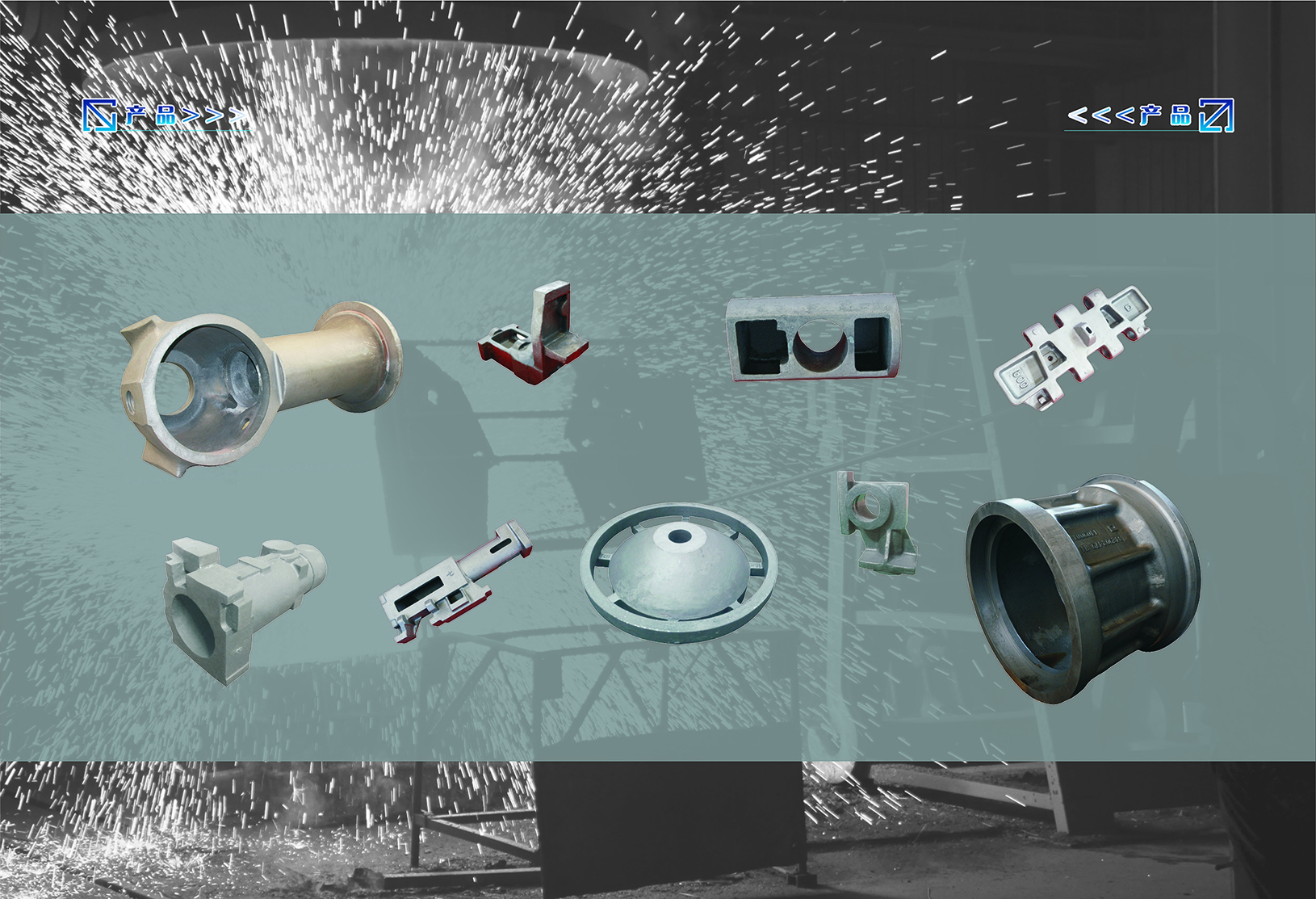

The Evolution and Importance of Casting Product Manufacturers

Casting is one of the oldest manufacturing processes known to humanity, tracing its origins back thousands of years. It involves pouring liquid material—typically metal, but also ceramics or plastics—into a mold to create specific shapes and forms. The role of casting product manufacturers is crucial in today’s industrial landscape, as they provide the foundation for numerous sectors including automotive, aerospace, construction, and consumer goods.

The casting process can be categorized into several methods, including sand casting, investment casting, die casting, and lost foam casting. Each method has its unique advantages and limitations, which influence the choice of process based on factors like material type, production volume, and desired accuracy. For instance, die casting is preferred for high-volume production due to its efficiency and the excellent surface finish it offers, while investment casting is ideal for complex shapes and high precision.

Over the years, the casting industry has undergone significant transformations driven by technological advancements. The emergence of computer-aided design (CAD) and computer-aided manufacturing (CAM) has revolutionized the way casting products are designed and produced. These technologies enable manufacturers to simulate the casting process, predict potential defects, and refine designs before actual production. This not only enhances productivity but also minimizes waste and reduces costs.

casting product manufacturer

Sustainability has become a key focus for casting product manufacturers as well. The industry is actively exploring ways to reduce energy consumption and minimize the environmental footprint of the casting process. Innovations such as using recycled materials and incorporating energy-efficient equipment are becoming increasingly common. Furthermore, many manufacturers are adopting lean manufacturing principles to streamline their operations, thereby enhancing productivity while also contributing to environmental sustainability.

The role of casting product manufacturers extends beyond just producing parts; they are also integral in driving innovation and improving product performance. By collaborating closely with design engineers and end-users, these manufacturers can develop bespoke solutions tailored to specific application requirements. This collaborative approach fosters a deeper understanding of customer needs and leads to the creation of high-quality products that meet rigorous industry standards.

In conclusion, casting product manufacturers are vital players in the global manufacturing arena. Their expertise in various casting methods, commitment to technological advancement, and dedication to sustainability position them as key contributors to various industries. As consumer demands evolve and the push for sustainability intensifies, the role of these manufacturers will continue to expand, adapting to meet the challenges of the future while delivering innovative casting solutions.

-

High-Precision Colloidal Silica Casting Solutions Custom & ODM

NewsMay.20,2025

-

High-Efficiency Cast Silico Aluminum Gas Boiler ODM & Custom Solutions

NewsMay.20,2025

-

Steel Reinforced Concrete Pipe Bottom Ring Moulds Buy Custom Solutions

NewsMay.19,2025

-

Original Concrete Pipe Mold Bottom Ring & Pallet Chinese Factory Direct Sale

NewsMay.19,2025

-

Custom Room Heating Heat Exchangers Energy-Efficient Solutions

NewsMay.18,2025

-

Precision Milling Body Casting Solutions Custom & ODM Options

NewsMay.18,2025