- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

12-р сар . 01, 2024 17:46 Back to list

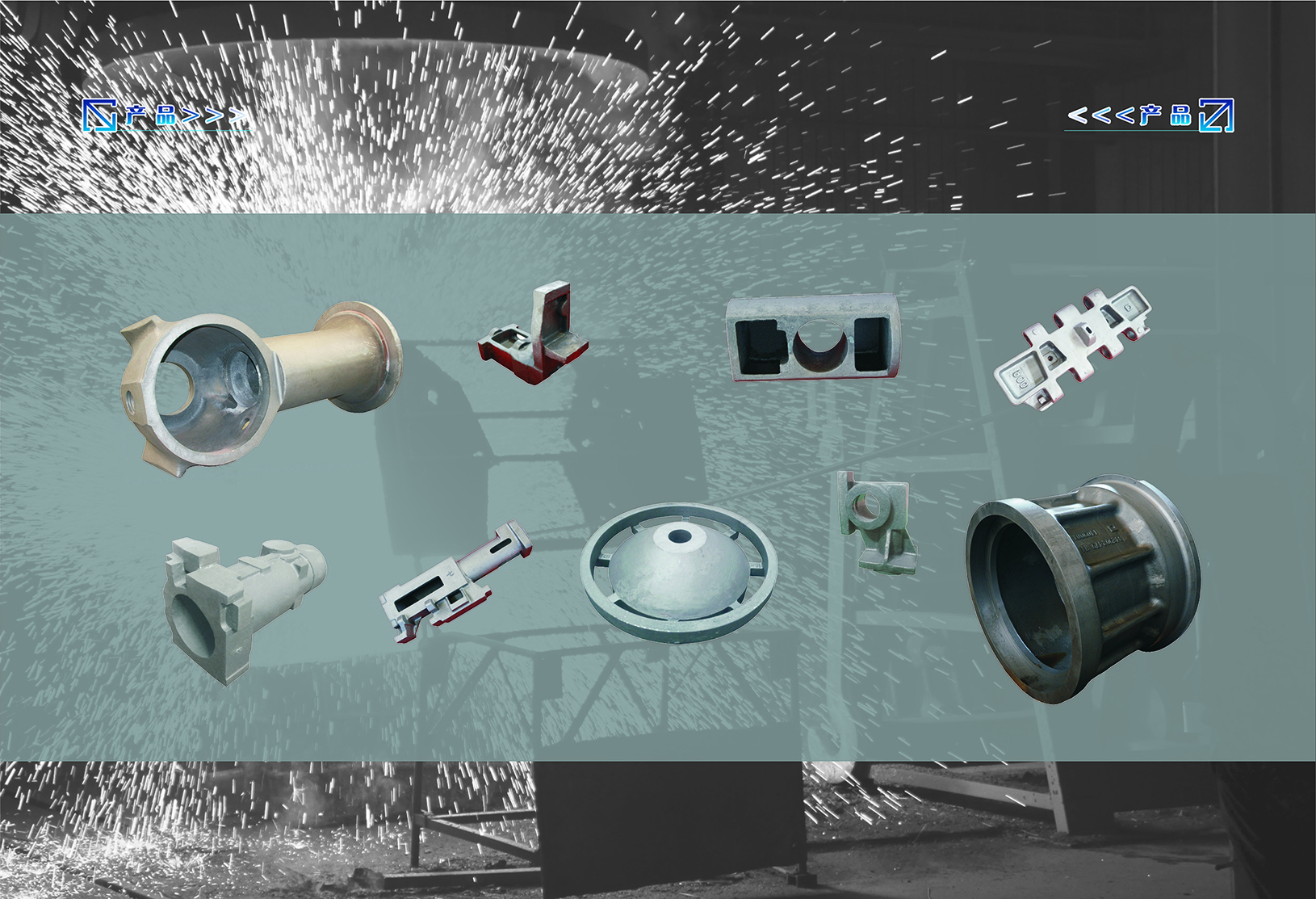

Exploring the Benefits and Applications of Ductile Iron Castings in Modern Manufacturing

The Significance of Ductile Castings in Modern Engineering

Ductile castings, also known as ductile iron castings, have emerged as a pivotal material in the realm of modern engineering and manufacturing. Characterized by their unique mechanical properties, ductile castings offer a blend of strength, flexibility, and impact resistance that sets them apart from traditional cast iron materials. As industries increasingly demand materials that can withstand dynamic loads and harsh environments, understanding the advantages and applications of ductile castings becomes essential.

One of the primary characteristics of ductile castings is their enhanced tensile strength and ductility compared to conventional gray cast iron. This is attributed to the presence of spherical graphite structures within the iron matrix, which allow for greater deformation without fracture. As a result, ductile iron can absorb shock and stress, making it ideal for components subjected to high impact and fatigue. In applications ranging from automotive parts to heavy machinery, the ability to endure rigorous conditions while maintaining structural integrity is crucial.

The versatility of ductile castings extends beyond their mechanical properties. They can be easily cast into complex shapes, enabling manufacturers to produce intricate components while minimizing machining requirements. This not only reduces production time and costs but also allows for innovative designs that enhance product functionality. Industries such as automotive, aerospace, and construction benefit significantly from this manufacturing efficiency, enabling them to meet the demands of rapid product development and customization.

ductile castings

In addition to mechanical strength and design flexibility, ductile castings also display excellent corrosion resistance. With appropriate alloying elements and proper treatment, ductile iron can resist oxidation and wear, making it suitable for both indoor and outdoor applications. For instance, in municipal infrastructure, ductile iron pipes are favored for their durability and low maintenance requirements, effectively transporting water and wastewater without the risk of leaks or failures.

The environmental aspect of ductile castings is also noteworthy. The manufacturing process for ductile iron is energy-efficient, often utilizing recycled scrap metal as a primary raw material. This not only reduces the carbon footprint associated with production but also supports sustainability efforts within various industries. As organizations strive to minimize their environmental impact, the adoption of ductile castings represents a step towards responsible manufacturing practices.

Despite their many advantages, it is essential to consider the limitations of ductile castings. While they are incredibly strong, they are not as suitable for extremely high-temperature applications or environments where they could be subjected to severe corrosion without protective coatings. Additionally, the costs associated with alloying and advanced processing methods can sometimes exceed those of traditional materials. Therefore, engineers must evaluate the specific requirements of their applications to determine the most suitable material choice.

In conclusion, ductile castings have established themselves as a cornerstone of modern engineering, offering remarkable strength, flexibility, and resistance to various environmental conditions. Their ability to be cast into complex shapes allows for innovation in design and efficiency in manufacturing, meeting the diverse needs of industries today. With an emphasis on sustainability and durability, ductile iron continues to play a crucial role in advancing engineering solutions. As technology evolves and industries seek out more resilient materials, ductile castings will undeniably remain a fundamental choice for engineers and manufacturers alike.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025